Automatic differential pressure balance type valve position indicator

An automatic balance and indicator technology, applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve the problems of non-operation of gears, high requirements for bearing type selection and quality, high tolerance and assembly requirements of gear seats and upper and lower connecting blocks, etc. Achieve the effects of reducing mechanical wear and running resistance, reducing processing technology and assembly accuracy requirements, and improving measurement accuracy and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

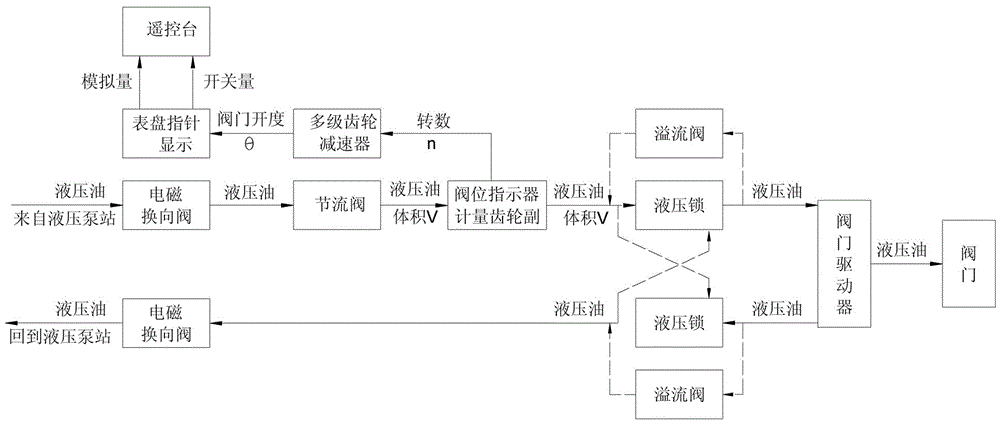

[0025] According to attached figure 1 , is the working principle diagram of the differential pressure automatic balance valve position indicator. The device includes electromagnetic reversing valve, throttle valve, differential pressure automatic balance valve position indicator, hydraulic lock, overflow valve, hydraulic driver, valve, pressure oil pipe, electrical interface, etc.

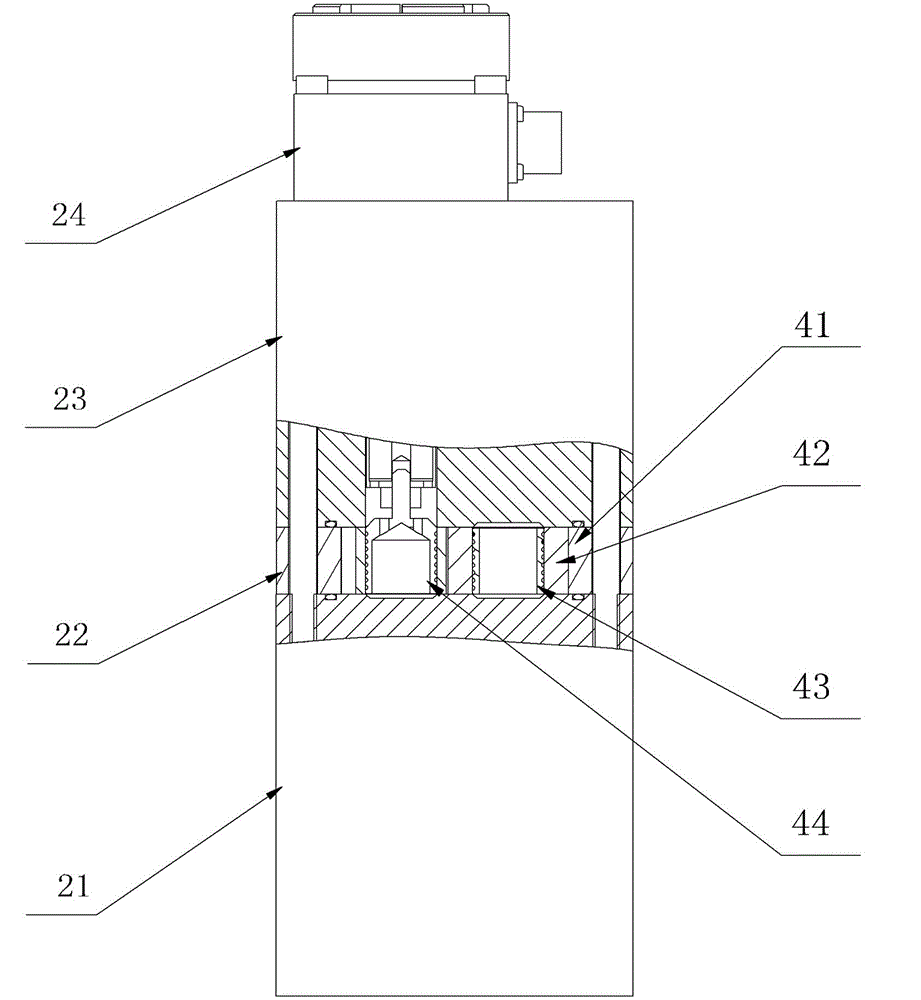

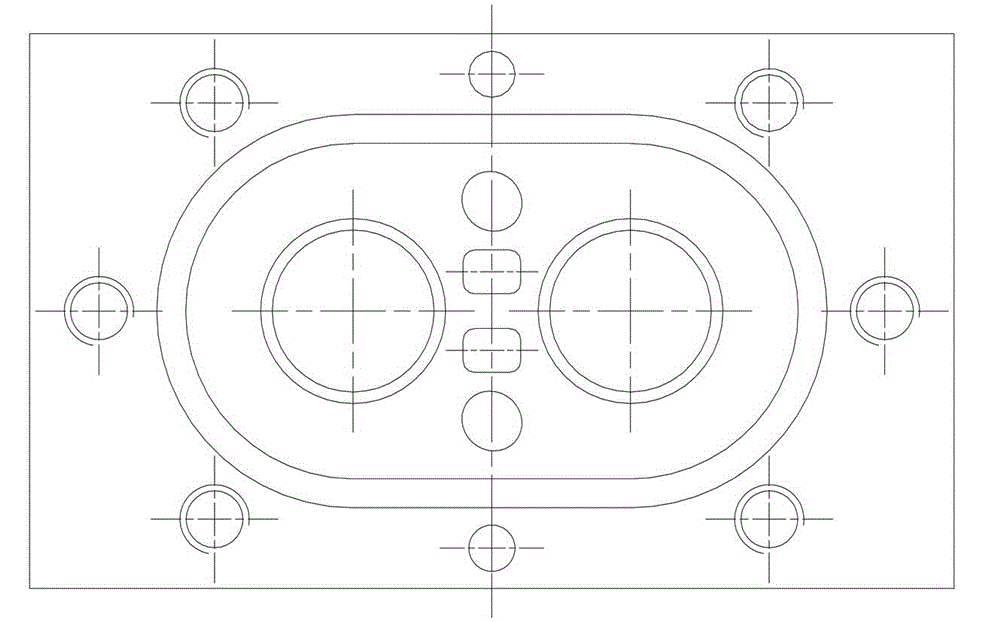

[0026] The hydraulic oil from the power pump station enters the oil inlet cavity of the metering gear pair 22 of the pressure difference automatic balance valve position indicator after passing through the electromagnetic reversing valve and the throttle valve to adjust the flow rate, and drives a pair of metering gears 42 to rotate. In this way, the volumetric flow measurement is realized, and the measured hydraulic oil is then sent to the valve driver through the hydraulic lock. The low-pressure hydraulic oil at the oil return port of the valve driver passes through the hydraulic lock, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com