Hydraulic variable-speed transmission device

A transmission and hydraulic speed change technology, applied in transmission, fluid transmission, transmission control, etc., can solve the problems of high energy consumption, power energy conversion efficiency is not brought into full play, and mechanical transmission efficiency is low. The effect of strong overload capacity, reducing input power and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

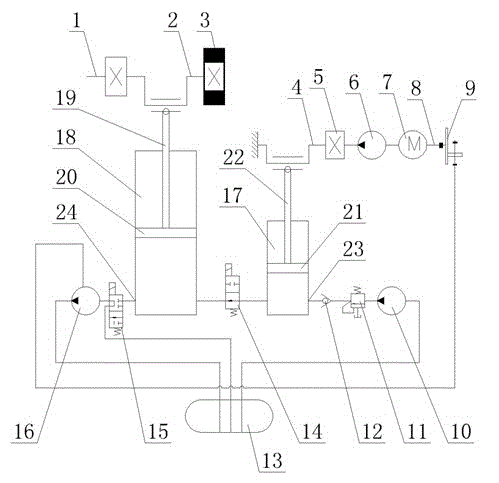

[0023] This embodiment provides a hydraulic transmission device, see figure 1 , the transmission device includes: a large hydraulic cylinder 18, a small hydraulic cylinder 17, a hydraulic oil tank 13, a stepless speed regulating device 9 and a drive motor 7, the large hydraulic cylinder 18 and the small hydraulic cylinder 17 are two mutually independent cylinder bodies, the large The hydraulic cylinder 18 and the small hydraulic cylinder 17 are connected by an oil pipeline, and a two-position two-way solenoid valve 14 is arranged on the oil pipeline connecting the large hydraulic cylinder 18 and the small hydraulic cylinder 17. The large hydraulic cylinder 18 and the small hydraulic cylinder 17 are communicated with the hydraulic oil tank 13 through the oil pipeline respectively.

[0024] A large piston 20 is arranged in the large hydraulic cylinder 18, and the large piston 20 is connected with the large piston crank mechanism 2 through the large piston connecting rod 19. One ...

Embodiment 2

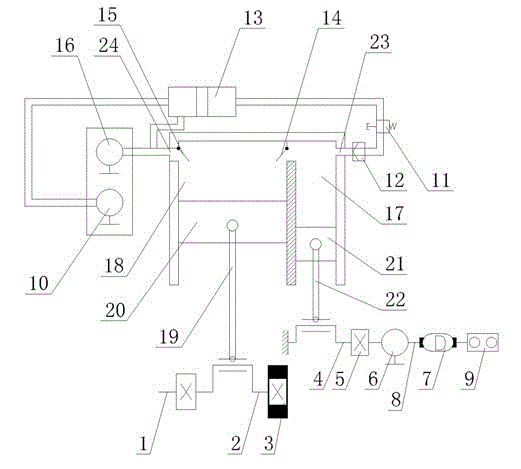

[0036] This embodiment provides a hydraulic transmission device, see figure 2 , the transmission device includes: a large hydraulic cylinder 18, a small hydraulic cylinder 17, a hydraulic oil tank 13, a stepless speed regulating device 9 and a drive motor 7, the large hydraulic cylinder 18 and the small hydraulic cylinder 17 are an integral cylinder with a partition Divided into. A communication hole is provided on the partition between the large hydraulic cylinder 18 and the small hydraulic cylinder 17, and a two-position two-way solenoid valve 14 is arranged at the communication hole, and the large hydraulic cylinder 18 and the small hydraulic cylinder 17 pass through the oil pipeline respectively. It communicates with the hydraulic oil tank 13.

[0037] A large piston 20 is arranged in the large hydraulic cylinder 18, and the large piston 20 is connected with the large piston crank mechanism 2 through the large piston connecting rod 19. One end of the large piston crank m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com