Process for heavy oil and bitumen upgrading

A technology for heavy oil and bitumen, applied in chemical instruments and methods, processing tar pitch/petroleum pitch/natural pitch by distillation, processing hydrocarbon oil, etc., can solve problems such as the inability to provide the usefulness of recirculating flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

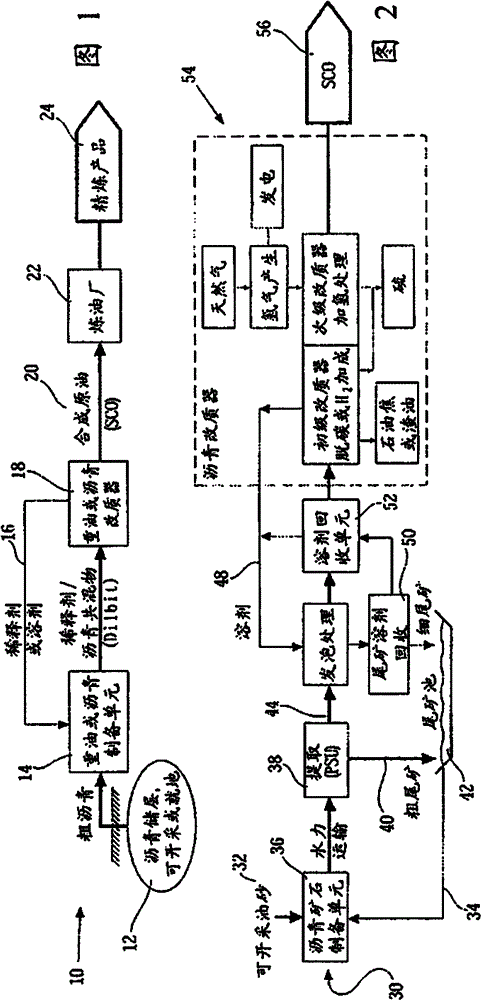

[0053] figure 1 A prior art method indicated at 10 is shown. Heavy oil or bitumen sources 12 may include recoverable or in-situ bitumen reservoirs. The bitumen may then be transported to preparation unit 14 into which a diluent or solvent may be introduced from reformer 18 via line 16 . The diluent or solvent may comprise any suitable material, such as a suitable liquid alkane. Once the diluent is introduced via line 16, a migratable bitumen blend (dilbit) is obtained. Once the diluted asphalt blend is processed in upgrader 18, the resulting synthetic crude product 20 is then processed in refinery 22 to subsequently produce a refined product represented by 24.

[0054] Preparation unit 14 primarily removes water and solids from the stream. Solvent 16 is added to the crude bitumen to provide the necessary migration and separation parameters, primarily a reduction in viscosity. In the case of bitumen derived from oil sands, water is added to the feedstock to provide a slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com