Flame straightening in a furnace

一种火焰、炉子的技术,应用在燃烧类型、照明和加热设备、非催化热裂化等方向,能够解决不能消除等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

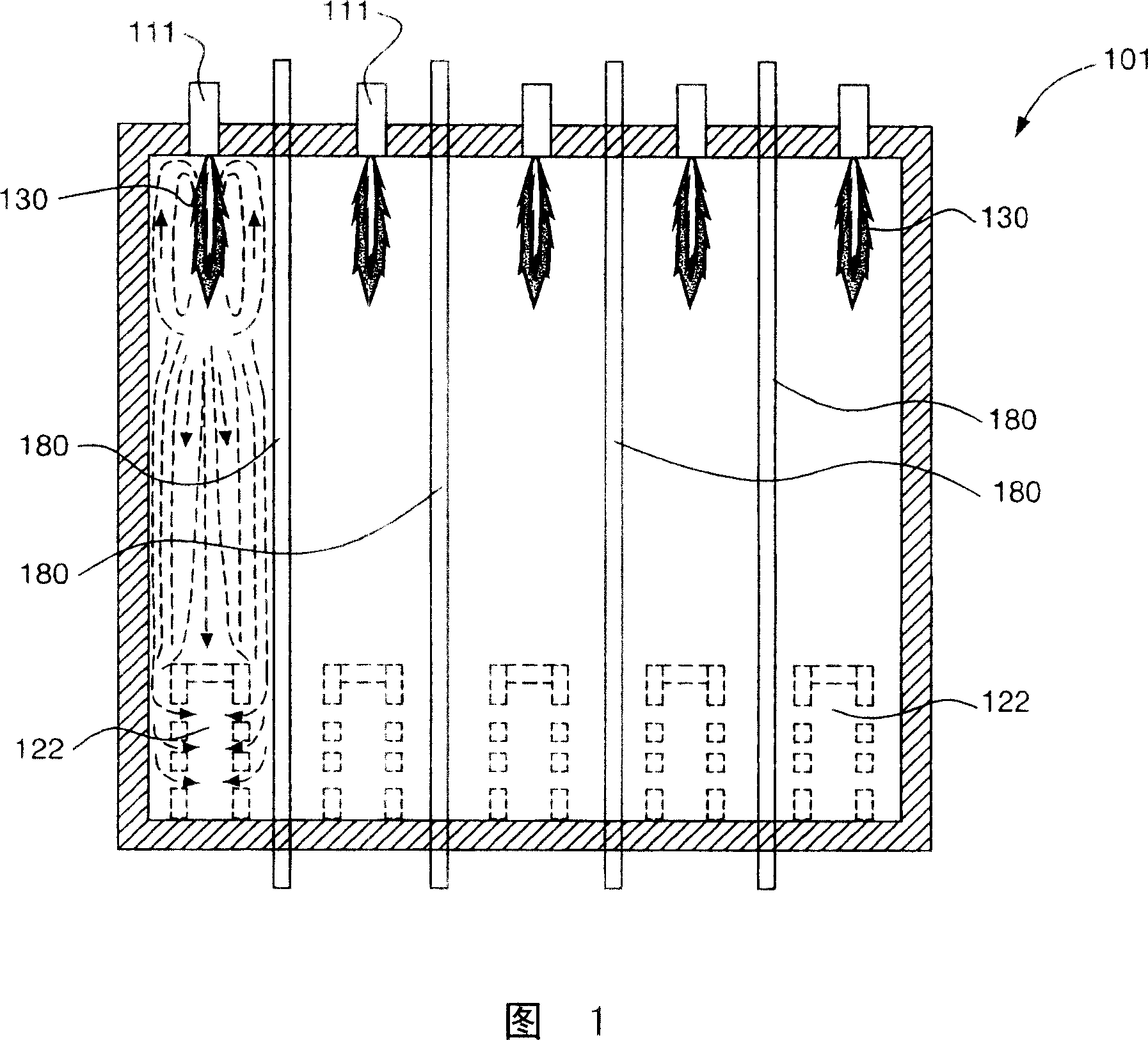

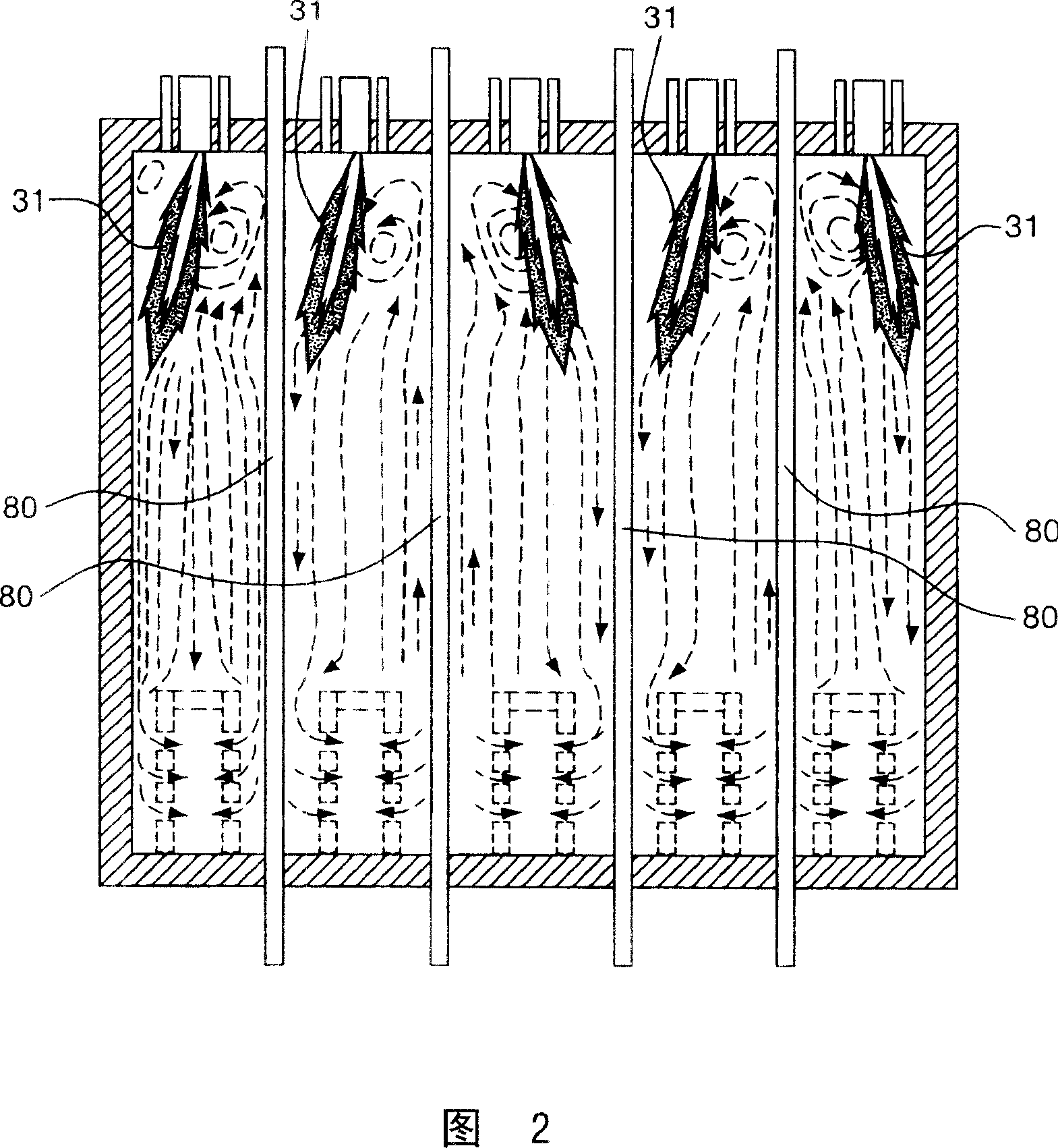

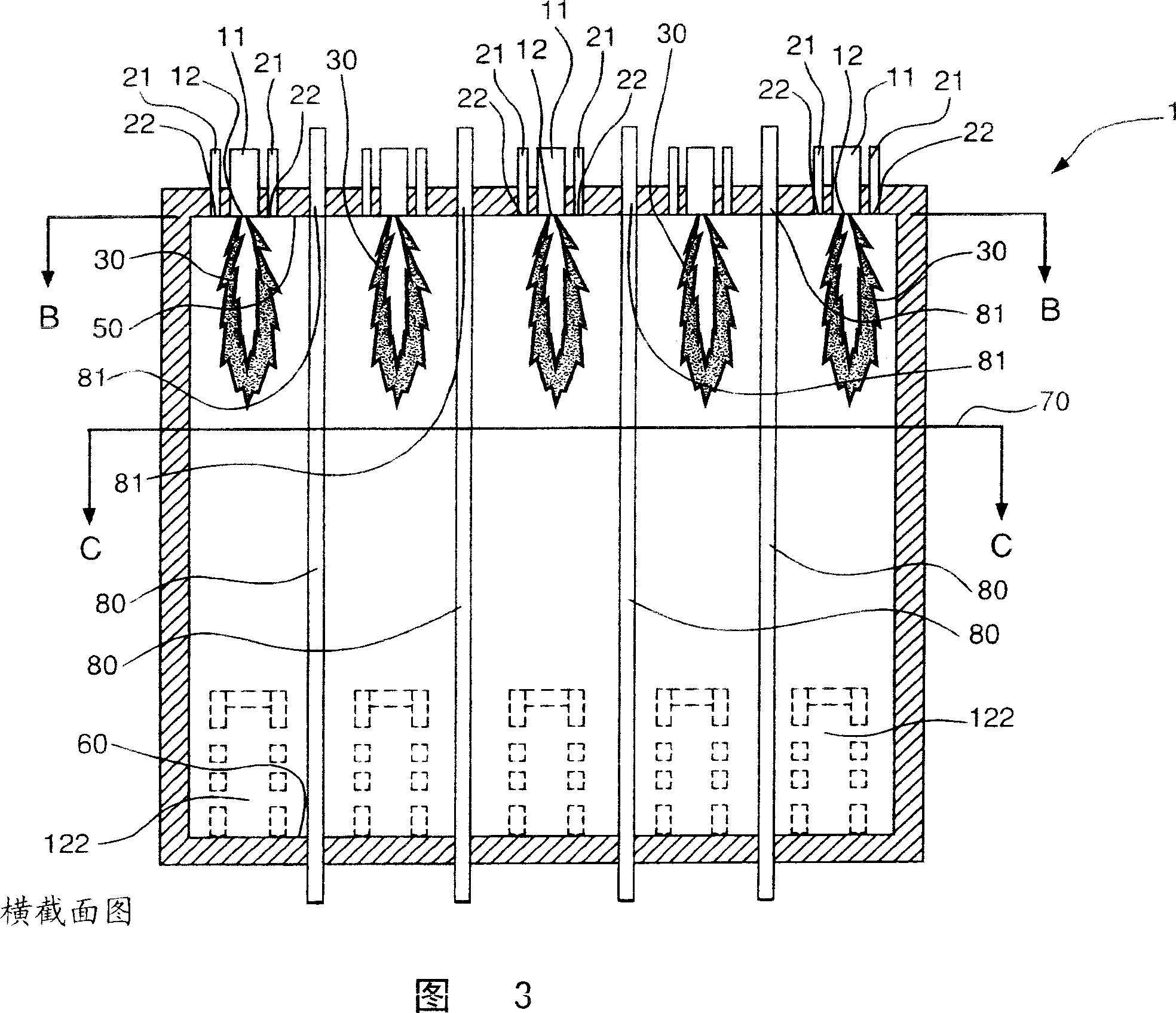

[0038] In one embodiment of the invention, the invention relates to a method of generating a straightening flame in a furnace. Referring to FIG. 3, which illustrates a cross-sectional view of the furnace 1, the method of the present invention includes introducing an oxidant into a plurality of oxidant pipes 11. The oxidant includes oxygen, and may additionally include fuel and / or combustion products. The oxidant may be air. The oxidant may include at least 10% oxygen by volume. The oxidant can be formed by pre-combustion of fuel and air in the pre-burner and is introduced through the oxidant pipe. The oxidant can be at ambient temperature or can be heated above ambient temperature.

[0039] The oxidant pipe 11 has an outlet 12 fluidly connected to the inside of the furnace 1, wherein the outlet 12 is closest to the inner end 50 of the furnace 1. The oxidant outlet 12 may be flush with the inner end 50. As shown in FIG. 3, the furnace 1 also has an inner end 60 opposite to the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com