Erasable white board ink and manufacturing method thereof

An ink and whiteboard technology, applied in the field of ink, can solve problems such as low stability, affecting the user experience of end consumers, and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

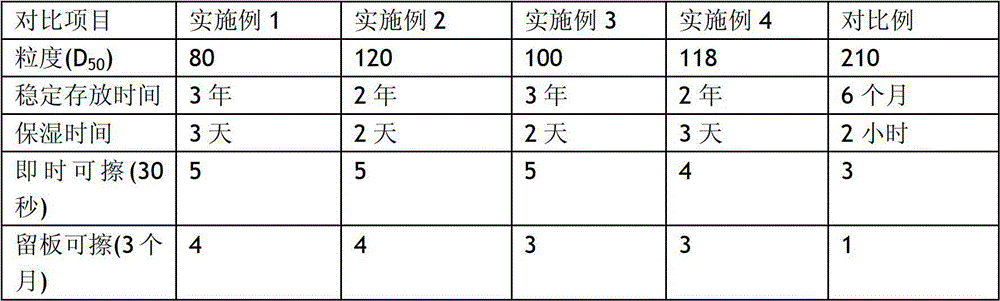

[0072] The preparation method of the erasable whiteboard ink of the present invention comprises the steps of: using a high-speed disperser to mix pigments, film-forming resins, humectants, emulsifiers, dispersants and appropriate solvents; Processed to obtain color paste, the particle size reaches D 50 = 80-120 nanometers; adding surfactants and film-forming aids to the color paste, diluting with a solvent, and shearing and dispersing to obtain the erasable whiteboard ink described in claim 1.

[0073] The "particle size reaches D 50 =80-120 nanometers" means: 50% of the particles have a particle size of 80-120 nanometers.

[0074] The preparation method of the present invention includes a high-pressure collision step. Specifically, the materials mixed by the high-speed disperser first go through a high-pressure collision step of 40 MPa, and then undergo high-speed sand milling.

[0075] The advantages of the present invention are:

[0076] (1) Long-term storage stability ...

Embodiment

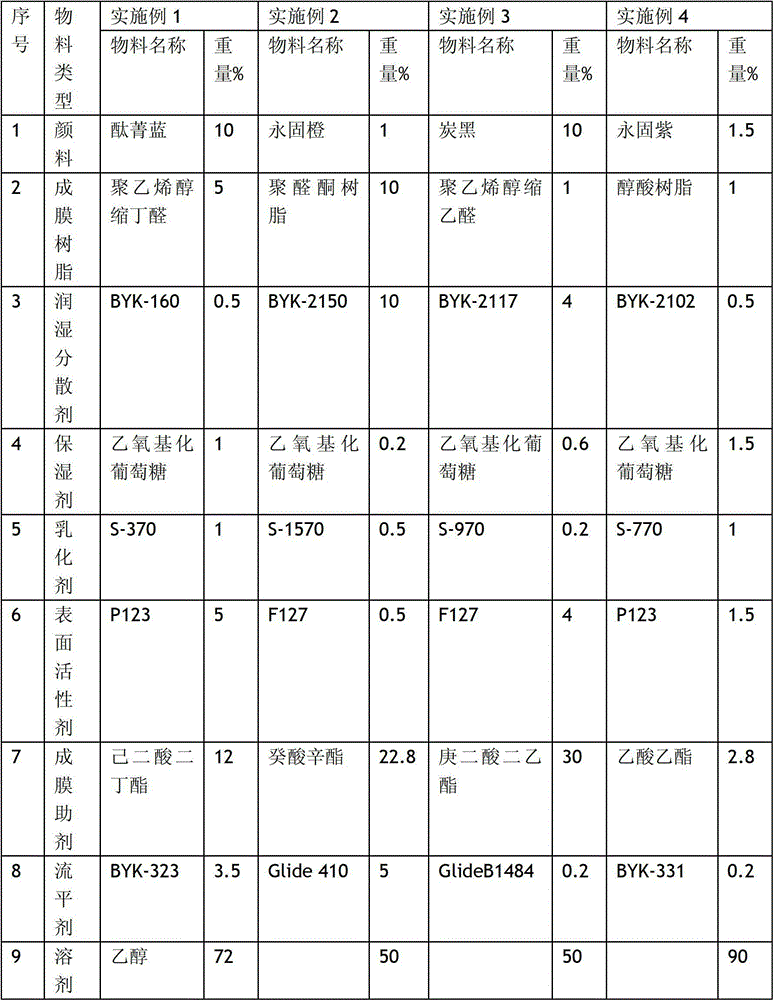

[0081] The formula of embodiment 1-4 is as shown in ink formula table 1:

[0082] Ink formula table 1

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com