Dense stacking burning die for RM type magnetic material product

A technology of magnetic materials and molds, which is applied in the field of close-packed and stacked firing molds, can solve the problems of lower pass rate, low pass rate, deglue cracking, etc., and achieve improved pass rate and production efficiency, good electrical performance and safety, and increased The effect of deglue gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

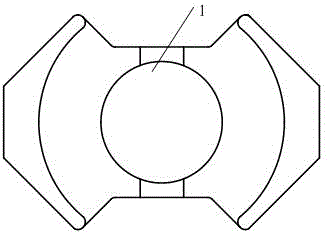

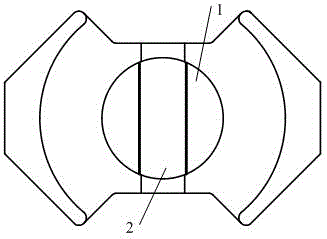

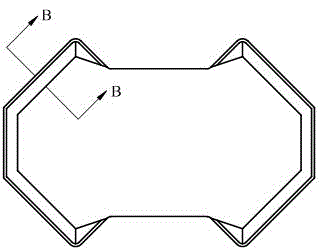

[0023] According to an embodiment of the present invention, a close-packed stacked firing mold for RM-type magnetic material products is provided. Such as Figure 1-Figure 6 As shown, this embodiment includes a mold body with a central column (such as the central column 1 ), and a groove (such as the groove 2 ) longitudinally provided at the center of the central column.

[0024] Preferably, the cross section of the groove is a rectangular groove; the width of the groove is half the radius of the cylinder where the central column is located; the depth of the groove is 0.13-0.17mm (preferably 0.15mm).

[0025] The close-packed stack-fired mold for the RM-type magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com