Numerical control driving device of crank-connecting rod-toggle rod plate shearing machine

A technology of crank connecting rod mechanism and driving device, applied in shearing device, shearing machine equipment, metal processing equipment and other directions, can solve the problems of low transmission efficiency, large width of guide rail, and oil leakage environment, etc., to improve the shearing width and precision, improve work efficiency, and the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

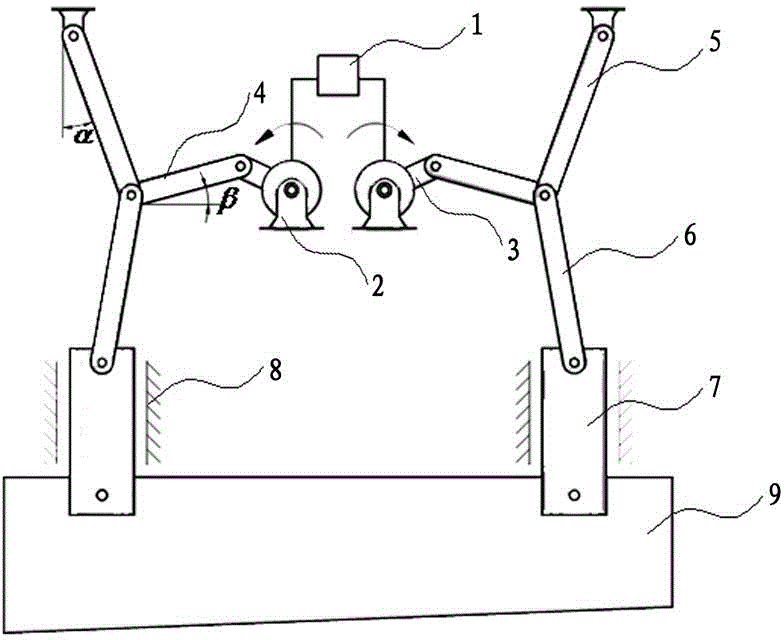

[0018] Embodiment one: see attached figure 1 shown.

[0019] Crank-connecting rod-knuckle rod shearing machine numerical control driving device, which includes a numerical control system 1, a motor 2, a transmission mechanism connected to the motor 2, a booster mechanism connected to the transmission mechanism, the first toggle lever 5, the second toggle lever 6, connected The slide block 7 of the booster mechanism, the slide block 7 is arranged in the chute 8, connects the moving tool rest 9 of the slide block, the transmission mechanism includes a crank linkage mechanism, and the booster mechanism includes the toggle mechanism, the first toggle lever 5, The second toggle 6, one end of the first toggle 5 is connected to the fuselage and the other end is connected to the second toggle 6, and the other end of the second toggle 6 is connected to the slider 7.

[0020] The crank-link mechanism includes a crank 3 and a connecting rod 4, one end of the crank is connected to the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com