Device and process adopted for rod-making by continuous casting and continuous rolling of red impure copper

A red miscellaneous copper and continuous casting technology, which is applied in the direction of metal rolling, can solve the problems of high resistivity of copper rods, unqualified product quality, poor pullability, etc., and achieve the goal of improving surface quality, good surface quality and reducing impurities volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

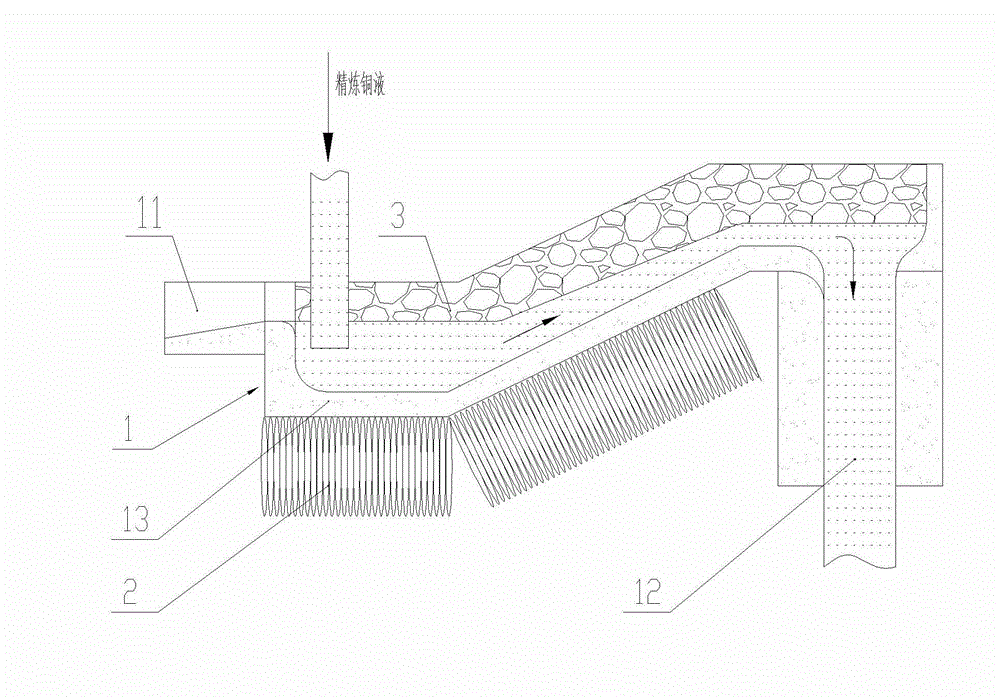

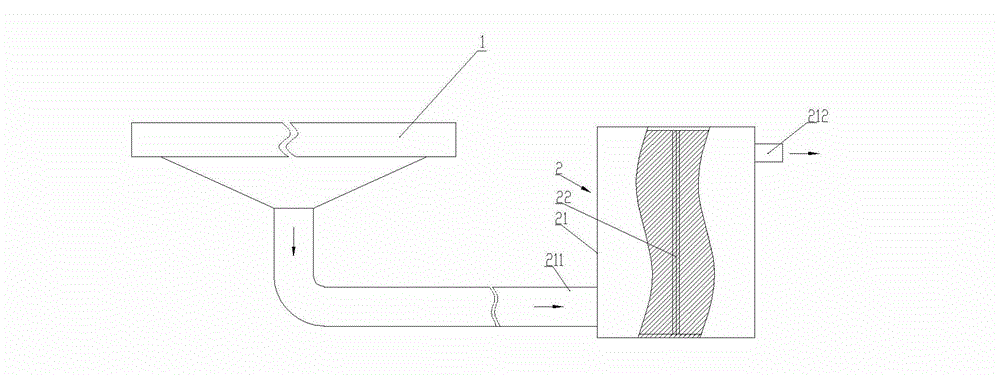

[0020] Example 1 Red miscellaneous copper is sorted by spectral measurement. The melting, oxidation and reduction furnace has a capacity of 80 tons. After batching, the copper content of this furnace is 99.89%, the lead content is 150mg / kg, the tin content is 560mg / kg, and the nickel content is 120mg. / kg, the rest of the impurity content is qualified. Add SiO 2 As a flux, the melting temperature is 1090°C, the melting time is 6.5 hours, and the slag is removed; the reverberatory furnace is used for oxidation and reduction treatment, the oxidation-reduction temperature is 1180°C, and oxygen at a pressure of 1.0MPa is introduced as an oxidant, and the oxidation time is 4 hours. Add pine wood As a reducing agent, the reduction time is 6 hours. Sampling analysis shows that the copper content is 99.91%, the lead content is 85mg / kg, the tin content is 420mg / kg, the nickel content is 108mg / kg, and the oxygen content is 0.049%. Electromagnetic refining device ( figure 1 ), the flo...

Embodiment 2

[0021] Example 2 Unlike Example 1, the copper content of red copper after batching is 99.90% , The zinc content is 230mg / kg, and the remaining impurities are qualified. The copper material is melted in a reverberatory furnace with a melting temperature of 1130°C and a melting time of 6 hours; it is oxidized and reduced in a reverberatory furnace with a redox temperature of 1130°C and an oxidation time of 5 hours. Natural gas is used as a reducing agent and the reduction time is 5 hours. Sampling and analysis showed that the copper content was lower than 99.90%. After the second oxidation and reduction, the copper content was 99.92% after repeated oxidation and reduction. , Zinc content 58mg / kg, oxygen content 0.025%. When the copper liquid flows through the electromagnetic refining device, the flow velocity is 0.17m / s, and the electromagnetic force received by each liter of copper liquid is 2000N. The angle of the copper liquid along the oblique upward direction is 26 degree...

Embodiment 3

[0022] Example 3 The difference from Example 1 is that the copper content of the mixed copper is 99.94%, the nickel content is 122.5 mg / kg, and the remaining impurities are qualified. It is melted in a shaft furnace with a melting temperature of 1100°C and a melting time of 6 hours. It is oxidized and reduced in a converter with a redox temperature of 1100°C. Sampling and analysis showed that the content of impurity elements in the copper liquid was qualified, the copper content was 99.94%, and the oxygen content was 0.022%. When the copper liquid flows through the electromagnetic refining device, the flow velocity is 0.20m / s, and the electromagnetic force received by each liter of copper liquid is 1900N. The angle of the copper liquid along the oblique upward direction is 21 degrees to the horizontal plane. The oxygen content of liquid copper passing through the electromagnetic refining unit dropped to 0.016%. The molten copper refined by the electromagnetic refining device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com