Phosphor and rare earth composite modification method of molecular sieve

A rare earth modification, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of long crystallization time, excessive consumption, and difficulty in forming core/shell molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

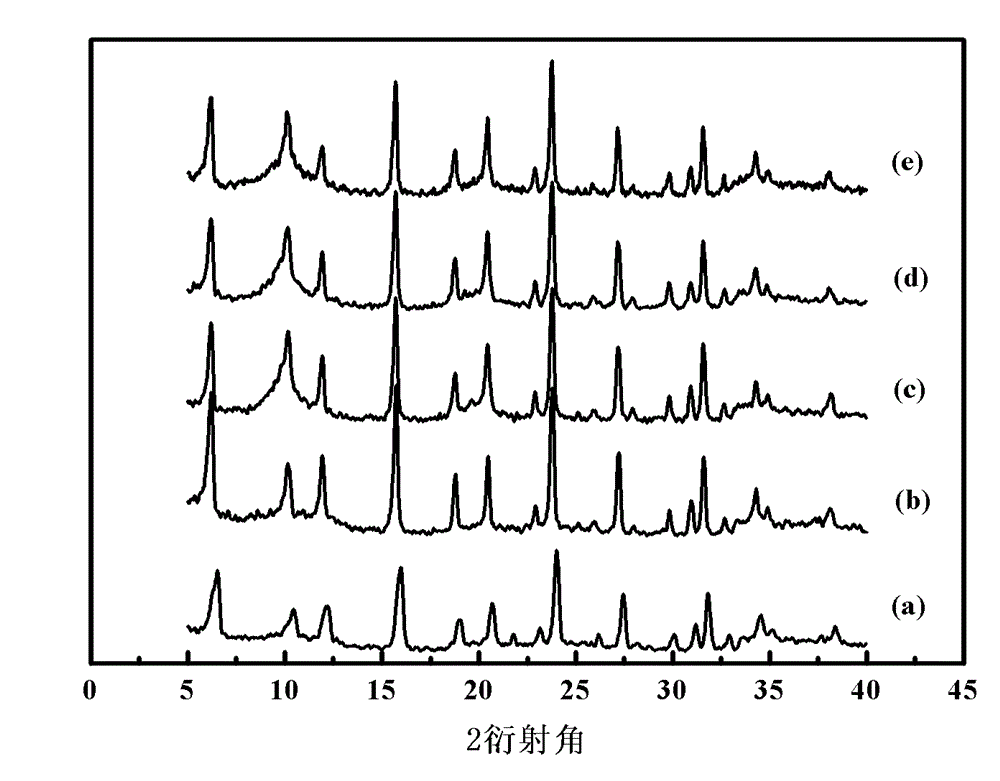

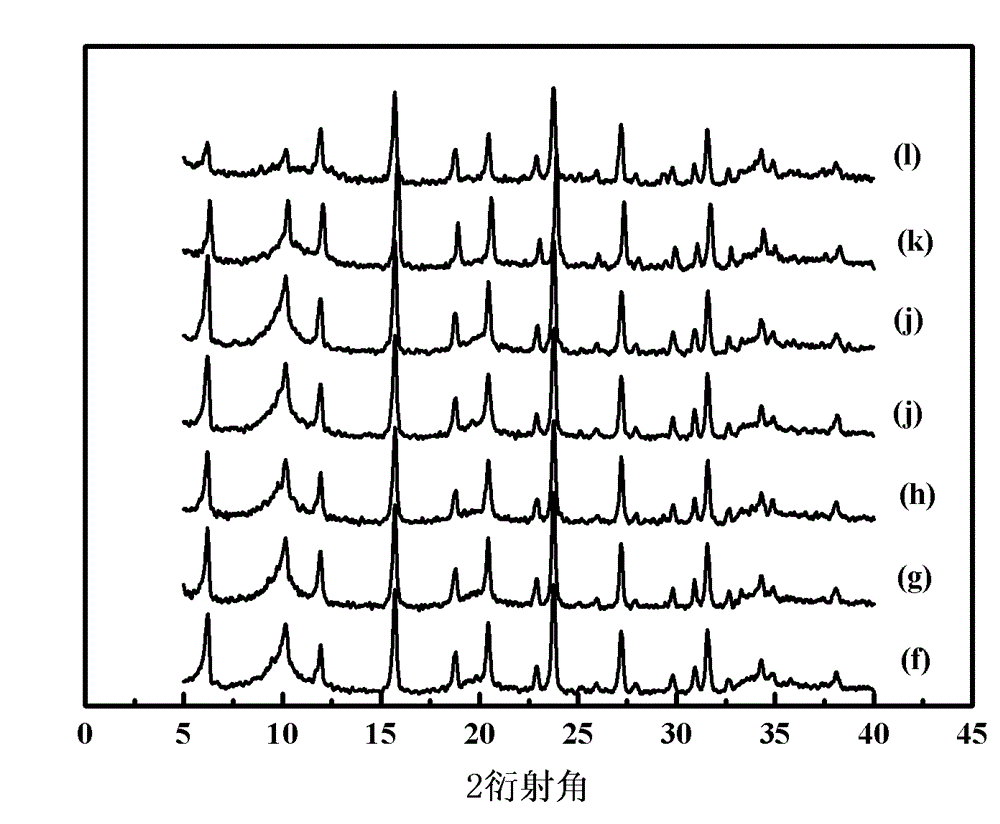

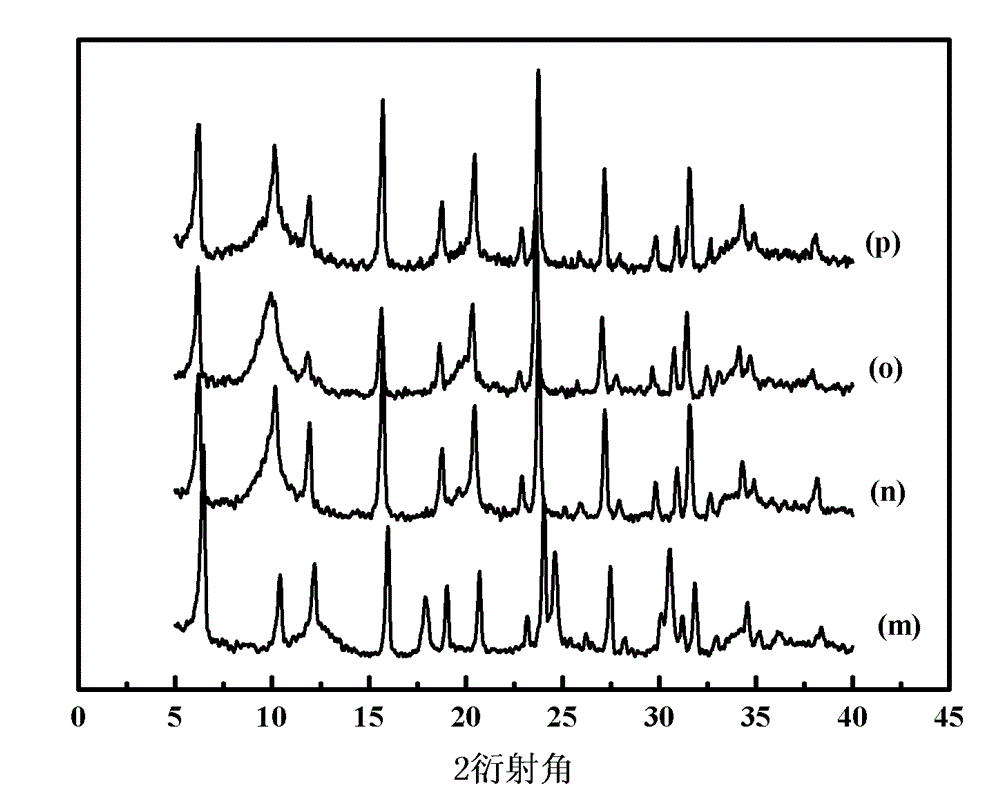

Image

Examples

Embodiment 1

[0081] Add 5g of USY molecular sieve into 50ml of deionized water, stir evenly at 40°C, add 7.437g of zinc nitrate, 1.84g of lanthanum nitrate, and 3.19g of aluminum nitrate in sequence, mix and stir for 0.5 hours, and add 40g / L of A mixed alkali solution of sodium hydroxide and sodium carbonate, adjust the pH value of the system to 6, stir for 4 hours under this condition, transfer to a high-pressure reactor, crystallize at 85°C for 24 hours, filter, wash and dry to obtain Zn- Al-La-CO 3 / USY Composite.

[0082] Will contain 5g Zn-Al-La-CO 3 / USY composite wet filter cake dissolved in 20mL deionized water to make a slurry, 1g of NaH 2 PO 4 2H 2 O (0.198mol) was dissolved in 10mL water to form a solution. Make NaH under stirring 2 PO 4 The solution was slowly added to the slurry and mixed with dilute HNO 3 The solution adjusts the pH of the system to about 4.5, and refluxes for 1 hour. The product was fully washed with deionized water to pH ≈ 7 and dried to obtain Zn / ...

Embodiment 2

[0084] Add 5g of USY molecular sieve into 50ml of deionized water, stir evenly at 20°C, add 7.437g of zinc nitrate, 2.71g of lanthanum nitrate, and 2.34g of aluminum nitrate in sequence, mix and stir for 0.5 hours, and add 40g / L of hydrogen at a rate of 1ml / min A mixed alkali solution of sodium oxide and sodium carbonate, adjust the pH value of the system to 6, stir for 6 hours under this condition, transfer to a high-pressure reactor, crystallize at 85°C for 24 hours, filter, wash and dry to obtain Zn-Al -La-CO 3 / USY Composite,

[0085] Will contain 10g Zn-Al-La-CO 3 The wet filter cake of the / USY composite was dissolved in 20 mL of deionized water to make a slurry, and 1 g of phosphoric acid was dissolved in 10 mL of water to make a solution. Slowly add orthophosphoric acid solution into the slurry under stirring, and dilute HNO 3 The solution adjusts the pH of the system to about 4.5, and refluxes for 1 hour. The product was fully washed with deionized water to pH ≈ 7...

Embodiment 3

[0087] Add 5g of USY molecular sieve into 50ml of deionized water, stir evenly at 20°C, add 13.73g of zinc nitrate and 2.67g of lanthanum nitrate in turn, mix and stir for 0.5 hours, add 80g / L of sodium hydroxide and carbonic acid at a speed of 0.1ml / min Mixed alkali solution of sodium, adjust the pH value of the system to 6, stir under this condition for 6 hours, transfer to a high-pressure reactor, crystallize at 85°C for 24 hours, filter, wash and dry to obtain Zn-Al-La-CO 3 / USY Composite.

[0088] Will contain 1g Zn-Al-La-CO 3 The wet filter cake of / USY composite material was dissolved in 20 mL of deionized water to make a slurry, and 1 g of phosphorous acid was dissolved in 10 mL of water to make a solution. Slowly add the phosphorous acid solution into the slurry under stirring, and dilute HNO 3 The solution adjusts the pH of the system to about 4.5, and refluxes for 1 hour. The product was thoroughly washed with deionized water to pH 7 and dried to obtain Zn-Al-La-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com