Method for preparing small-volume fat-soluble vitamin freeze-dried powder injection and its preparation device

A technology for fat-soluble vitamins and freeze-dried powder injections, which can be used in freeze-dried transportation, powder transportation, and pharmaceutical formulations. It can solve problems such as increased filling volume, low product output, and poor water solubility, and achieve reduced packaging Volume, improve product quality, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]

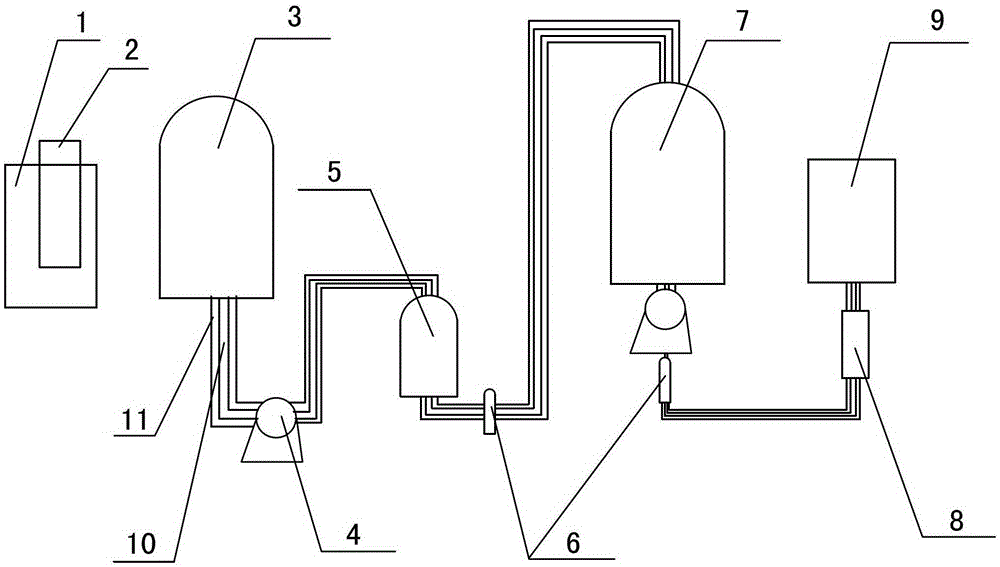

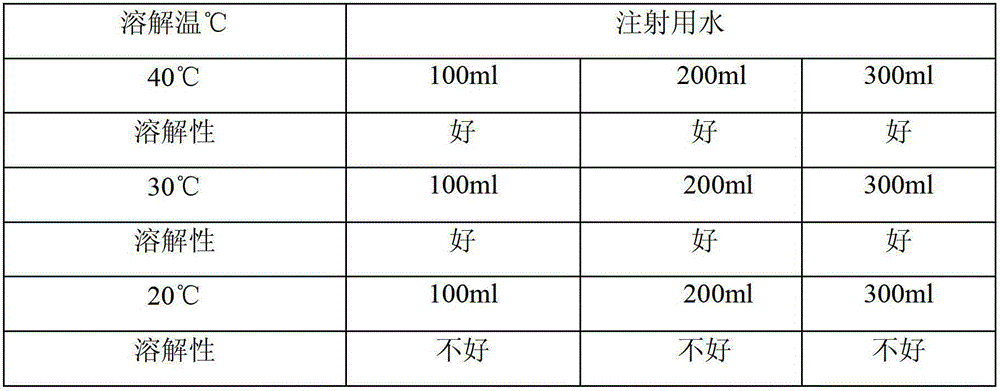

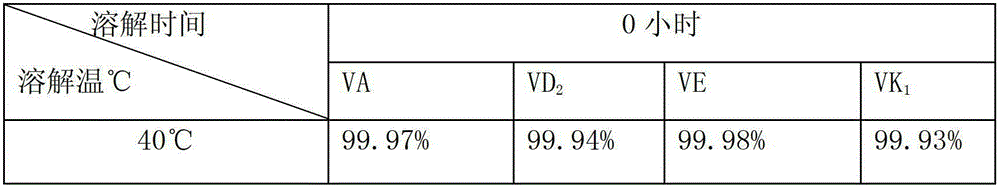

[0030] The preparation method of the small-volume fat-soluble vitamin freeze-dried powder injection is to weigh the prescribed amount of water for injection into the dispensing tank 3, turn on the stirring, and lower the temperature to 30℃-35℃, and release about 4% of the added amount of water for injection as dilution Water, spare. Add the prescribed amount of mannitol, stir to dissolve, and control the temperature at 30°C-35°C. The top and bottom of the tank are protected by nitrogen at the same time; this solution is considered as a liquid. Weigh the prescribed amount of Tween-80 and VE, and add them to stainless steel container 2 in turn, and then put the stainless steel bucket in the ultrasonic pool 1, turn on the ultrasonic, turn on the stirring, and ensure that the water temperature in the ultrasonic is 30-35°C, and stir. The whole process is protected by a hose with nitrogen. The solution is counted as liquid b, and vitamin K1, vitamin A, and vitamin D2 are add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com