Novel LED (light emitting diode) integrated light source module and preparation method thereof

A light source module and LED chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the luminous efficiency of LED devices, inconsistent thickness of LED chips, inconsistent light color of LED devices, etc., to improve luminous efficiency and light output. The effect of uniformity, reduced light energy loss, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The structure and preparation method of the present invention will be described in detail below based on the drawings.

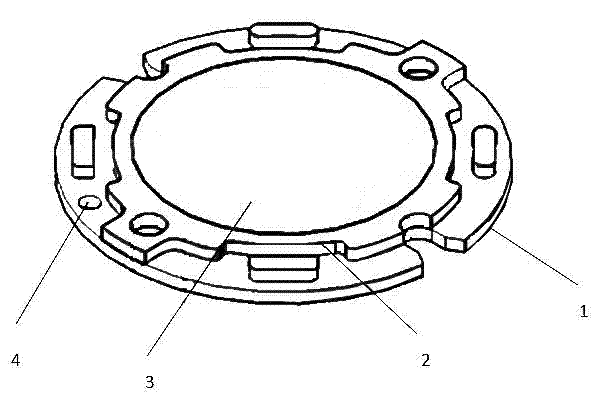

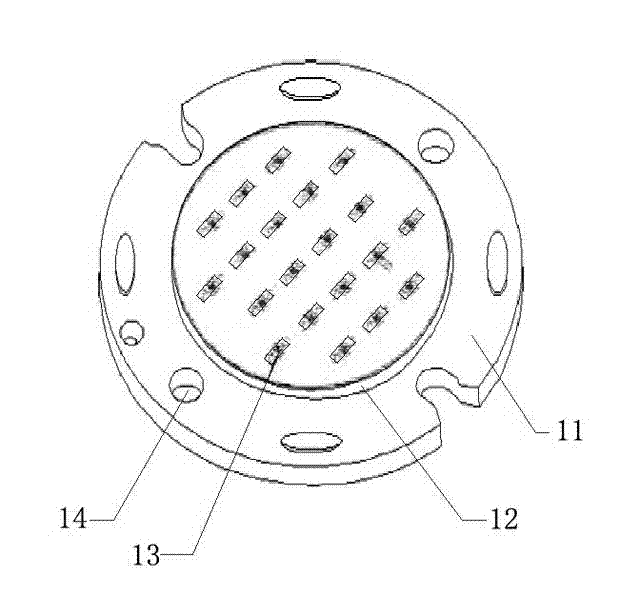

[0033] Reference figure 2 As shown, the novel LED integrated light source module of the present invention includes a substrate body 11, an LED die-bonding area 13, and a colloidal barrier wall 12 formed on the substrate body 1 by mixing and curing white or transparent silica gel and phosphor powder. The retaining wall 12 encloses the die bonding area into at least one enclosed area, the LED chip is arranged in the enclosed area, the height of the colloidal wall is 0.2-10mm, and the distance from the colloidal wall to the LED chip is between 0.05-30mm The colloidal retaining wall of the present invention is preferably a single-component white silicone rubber material; a positioning hole 14 is provided on the main body 11 of the substrate.

[0034] The manufacturing method of the novel LED integrated light source module of the present invention includes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com