Method for preparing semiconductor material through ion injection and fixed-point adsorption technologies

An ion implantation and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficulty in achieving low defect density and process instability, achieve low defect density, reduce process difficulty, and increase stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as Figure 1~Figure 9 As shown, this embodiment provides a method for preparing semiconductor materials using ion implantation and fixed-point adsorption processes, which at least includes the following steps:

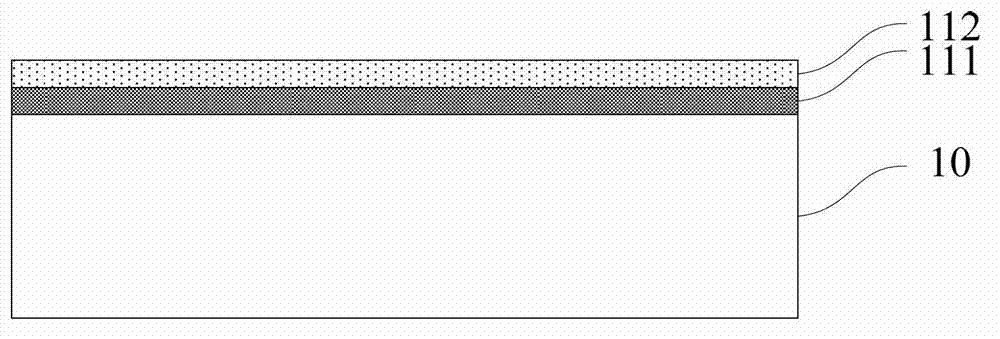

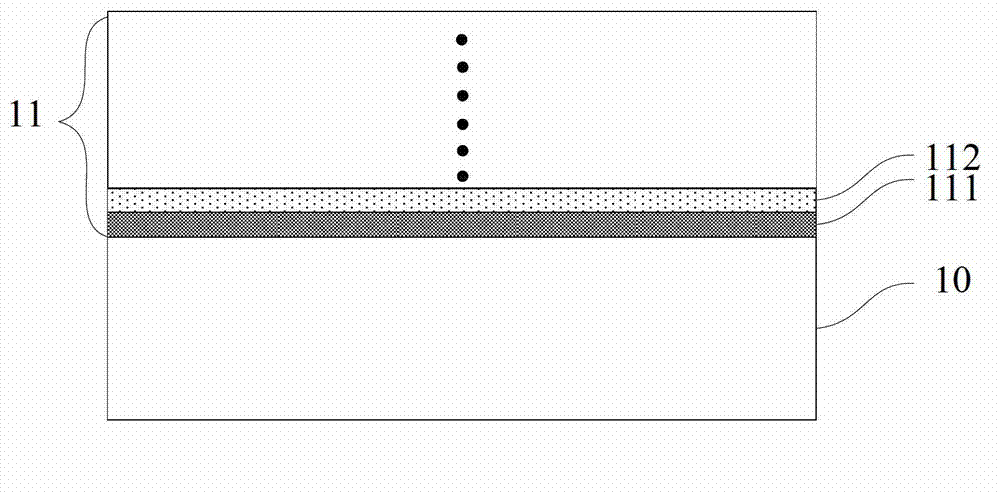

[0044] Such as Figure 1~Figure 2 As shown, step 1) is firstly performed to provide a first Si substrate 10, and Si substrates are alternately formed on the surface of the Si substrate. x Ge 1-x layer 111 and Si layer 112, forming at least one period of Si x Ge 1-x / Si superlattice structure 11, where 0≤x<1.

[0045] The Si x Ge 1-x The thicknesses of the layer 111 and the Si layer 112 are both 1-10 nm. In this embodiment, three periods of Si are formed on the surface of the first Si substrate 10 by chemical vapor deposition. x Ge 1-x / Si, wherein, x is 0.9, 0.8, 0.7 according to the order of formation, and the Si x Ge 1-x Both the layer 111 and the Si layer 112 have a thickness of 8 nm. Of course, in its embodiment, the Si x Ge 1-x The period...

Embodiment 2

[0060] Such as Figure 10~Figure 19 As shown, this embodiment provides a method for preparing semiconductor materials using ion implantation and fixed-point adsorption processes, such as Figure 10~16As shown, its steps 1)~step 3) are as step 1)~step 3) in embodiment 1, the subsequent steps of this embodiment are:

[0061] Such as Figure 17 shown, proceed to step 4), where the relaxed Si z Ge 1-z A strained Si layer 18 is formed on the surface of the layer 15, and the thickness of the strained Si layer 18 is less than its critical thickness.

[0062] The strained Si layer 18 is formed by chemical vapor deposition, since the relaxed Si z Ge 1-z Layer 15 has the characteristics of low defect density and high relaxation, so the Si layer grown on it has the characteristics of high strain and low defect density.

[0063] Such as Figure 18 As shown, proceed to step 5), providing a second Si substrate 17 with an oxide layer 16 on the surface, and bonding the oxide layer 16 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com