High strength polyacrylonitrile-base carbon fibers having structured surface grooves, and preparation method thereof

A polyacrylonitrile-based carbon fiber, high-strength technology, applied in the direction of fiber chemical characteristics, wet spinning, stretch spinning, etc., can solve the problems of improvement, disordered fiber surface grooves, and high preparation cost, and achieves easy polymerization control, High tensile strength, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Dimethyl sulfoxide solvent modification

[0041] Ammonia solution with a mass concentration of 35% and dimethyl sulfoxide were stirred in the kettle for 30 minutes at a ratio of 0.1:100 (volume ratio), so that they were thoroughly mixed to obtain a modified dimethyl sulfoxide solvent for use in acrylonitrile Coagulation bath configuration for polymerization and coagulation molding;

[0042] (2) Preparation of spinning dope

[0043] Acrylonitrile, itaconic acid, and methyl acrylate were blended and added to the polymerization reactor at a molar ratio of 98.5:0.5:1, and the modified dimethyl sulfoxide solvent was used as the solvent. The polymerization reaction temperature was controlled at 65°C, and the reaction time was 22 hours, an acrylonitrile copolymer with a polymer molecular weight of 150,000 was obtained. The obtained polymer solution has an acrylonitrile copolymer content of 21%;

[0044] (3) Solidification and molding of spinning dope

[0045] A spinner...

Embodiment 2

[0062] (1) Dimethyl sulfoxide solvent modification

[0063] Ammonia solution with a mass concentration of 35% and dimethyl sulfoxide were stirred in the kettle for 30 minutes at a ratio of 0.3:100 (volume ratio), so that they were fully mixed and uniform to obtain a modified dimethyl sulfoxide solvent;

[0064] (2)~(10) are the same as embodiment 1

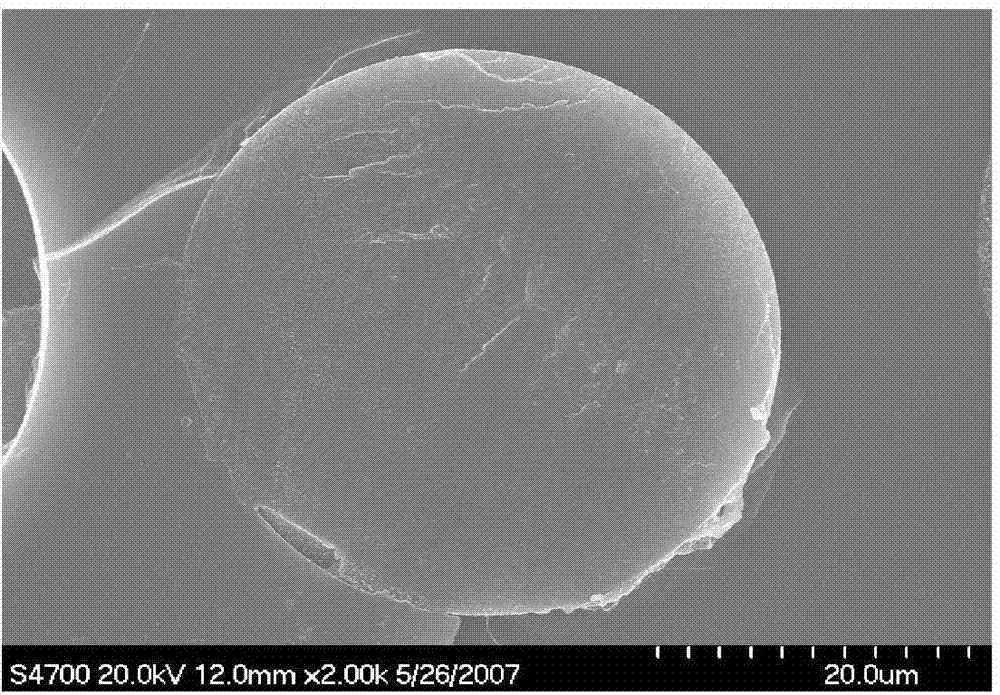

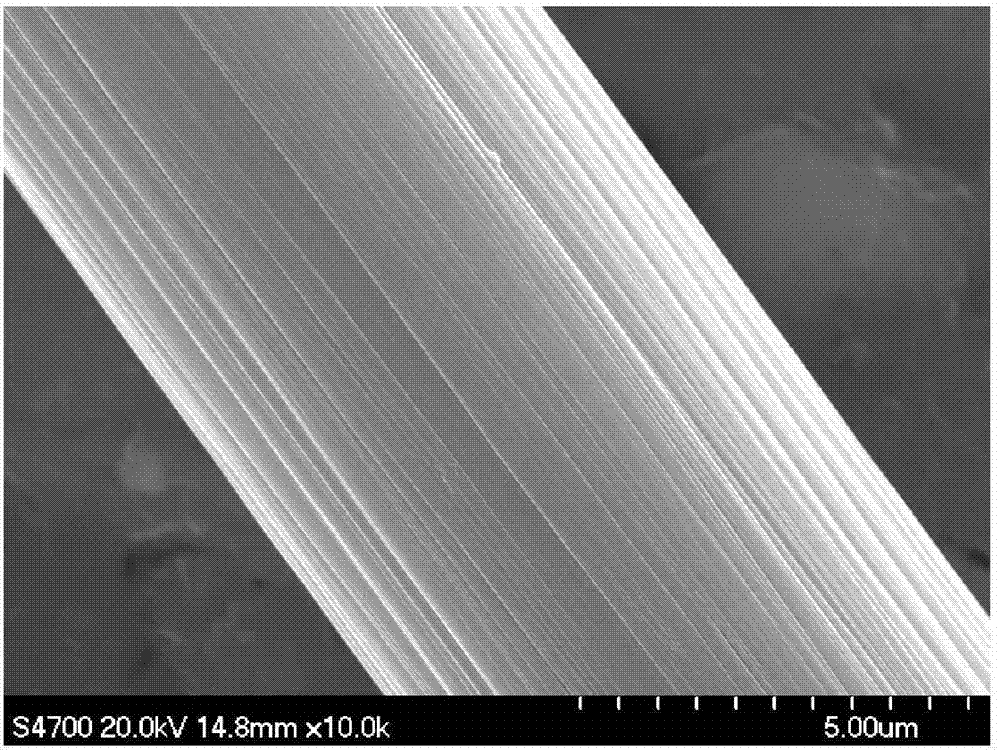

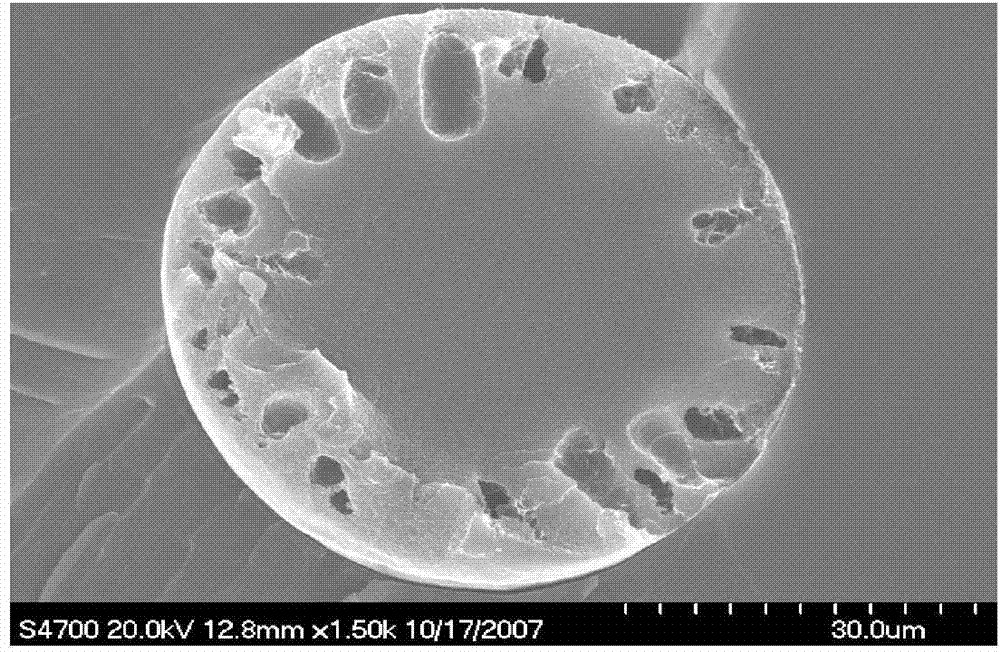

[0065] The performance of the carbon fiber produced: cross section: circular, diameter: 6.8μm, surface morphology: regular groove structure, density: 1.80g / cm 3 , Tensile strength: 5.28GPa, tensile modulus: 254GPa.

Embodiment 3

[0067] (1) with embodiment 1

[0068] (2) Preparation of spinning dope

[0069] Acrylonitrile, itaconic acid, and methyl acrylate were blended and added to the polymerization reactor at a molar ratio of 98.5:0.5:1, and unmodified dimethyl sulfoxide was used as a solvent. The polymerization reaction temperature was controlled at 65°C, and the reaction time was 22 hours, an acrylonitrile copolymer with a polymer molecular weight of 150,000 was obtained. The obtained polymer solution has an acrylonitrile copolymer content of 21%;

[0070] (3)~(10) are the same as embodiment 1

[0071] The performance of the carbon fiber produced: cross section: circular, diameter: 7.0μm, surface morphology: regular groove structure, density: 1.78g / cm 3 , Tensile strength: 5.15GPa, tensile modulus: 251GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com