Thin-wall austenite nodular cast iron impeller production technology

A nodular cast iron, production process technology, applied in the field of thin-walled austenitic nodular cast iron impeller production process, can solve the problems of poor flow performance of nodular cast iron, low production efficiency, difficult sand cleaning of castings, etc., and achieve excellent corrosion resistance and durability Abrasiveness and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

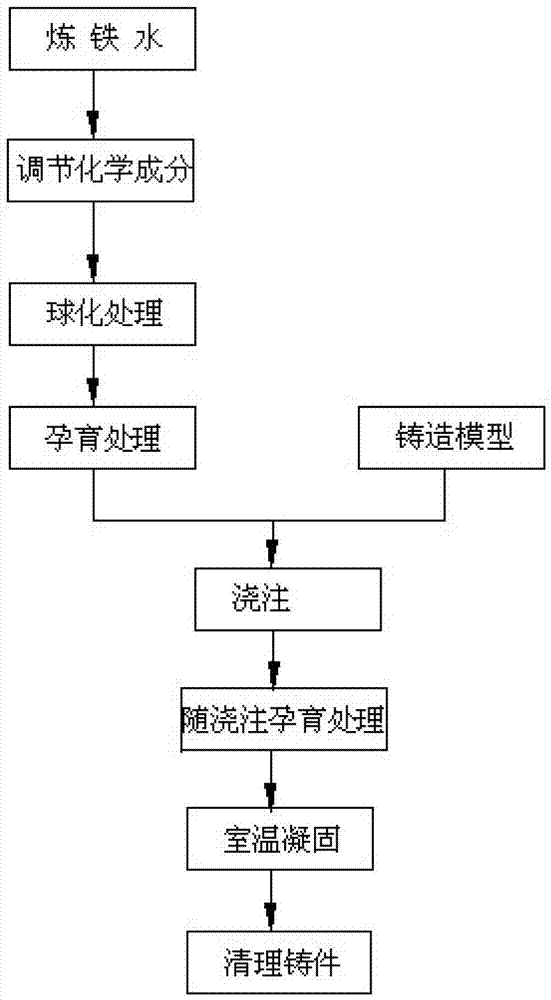

Method used

Image

Examples

Embodiment 1

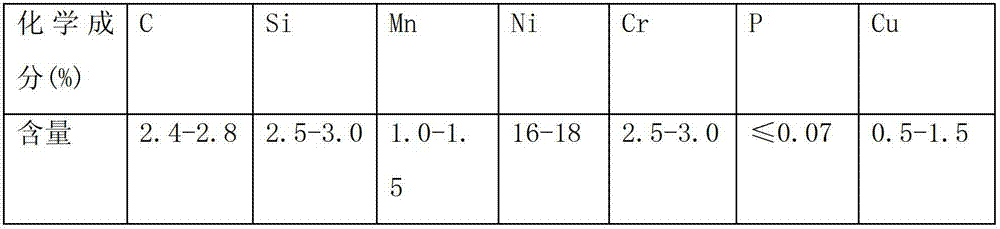

[0020] A. Melt cast iron in an intermediate frequency electric furnace, and use 75 ferrosilicon, strontium ferrosilicon, electrolytic nickel, electrolytic copper, 65 ferromanganese and 60 ferrochrome to adjust the chemical composition. Please refer to Table 1 for the chemical composition list;

[0021] Table 1:

[0022]

[0023] B. Add nickel-containing FeSiRe2Mg6 to the molten iron in A and carry out spheroidization treatment, the addition is 11%, and the spheroidization treatment adopts the flushing method, and the treatment temperature is 162°C;

[0024] C. adopt 0.3% 75 ferrosilicon, 0.25% strontium ferrosilicon to carry out inoculation treatment to the molten iron of B step;

[0025] D. Pouring the molten iron in step C into the impeller mold with clay sand or coated sand, and adopting 75 ferrosilicon to incubate with the flow during casting.

[0026] E. After cooling at room temperature until the molten metal is solidified, take out the casting and clean it up to ma...

Embodiment 2

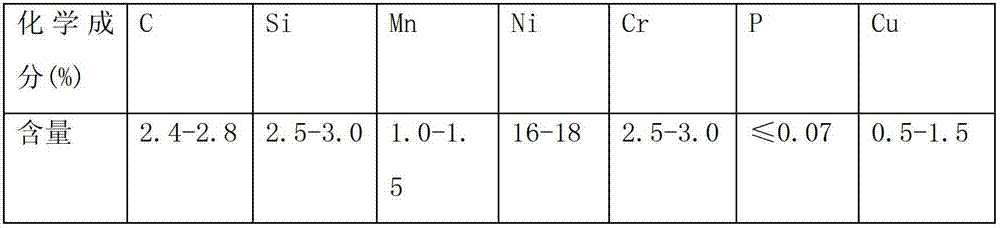

[0028] A. Melt cast iron in an intermediate frequency electric furnace, and use 75 ferrosilicon, strontium ferrosilicon, electrolytic nickel, electrolytic copper, 65 ferromanganese and 60 ferrochrome to adjust the chemical composition. Please refer to Table 1 for the chemical composition list;

[0029] Table 1:

[0030]

[0031] B. Add nickel-containing FeSiRe2Mg6 to the molten iron in A and carry out spheroidization treatment, the addition is 11%, and the spheroidization treatment adopts the flushing method, and the treatment temperature is 1650;

[0032] C. adopt 0.3% 75 ferrosilicon, 0.25% strontium ferrosilicon to carry out inoculation treatment to the molten iron of B step;

[0033] D. Pouring the molten iron in step C into the impeller mold with clay sand or coated sand, and adopting 75 ferrosilicon to incubate with the flow during casting.

[0034] E. After cooling at room temperature until the molten metal is solidified, take out the casting and clean it up to mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com