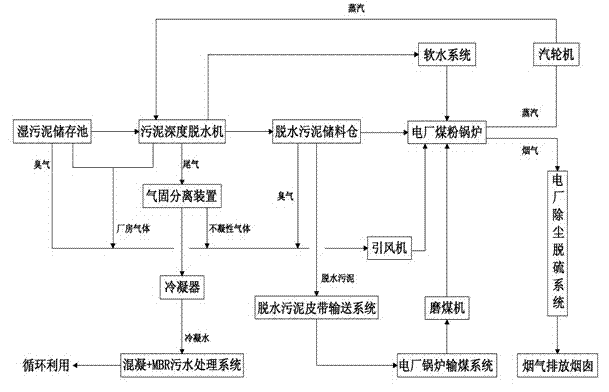

Treatment process of in-depth dehydration and resource utilization for sludge

A deep dewatering and recycling technology, applied in water/sludge/sewage treatment, sludge treatment, water/sewage multi-stage treatment, etc. Large engineering investment and other problems, to achieve the effect of simple exhaust gas treatment process, short construction period and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] As shown in the figure, the present invention can treat municipal sludge. The wet sludge is dumped into the wet sludge storage tank through the sludge transport vehicle. The upper part of the wet sludge storage tank is a half-closed and half-opened device. After dumping, the electric cover is automatically closed. A sieve plate is set above the wet sludge storage tank to prevent large pieces of foreign matter from entering the tank. At the same time, a sealed door is installed above the tank to prevent odor from escaping, and it is equipped with gas detection, collection and odor treatment systems.

[0039] A typical deep sludge dehydration device includes a centrifugal dehydrator and a heat source device: the structure of the centrifugal dehydrator is a horizontal centrifugal structure composed of a screw propeller and a drum, and the drum of the horizontal centrifugal dehydrator is provided with an inlet for sludge to be treated and the separated clear water outlet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com