Method for preparing anatase porous TiO2 spheres, core-shell structure and hollow spheres

A core-shell structure, anatase technology, applied in the field of photocatalytic materials, can solve problems such as limitations and hinder the development of template-free preparation methods and industrial applications, and achieve the effects of low cost, improved operability, and narrow size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] At room temperature, under the action of magnetic stirring, 2.0g (8mmol) Ti(SO 4 ) 2 Dissolve in deionized water to form a 60mL solution, add a certain amount of commercial analytical pure HNO to it 3 And dilute to 80mL with deionized water, so that the HNO 3 with Ti(SO 4 ) 2 The molar concentration ratio is 2:1. The above mixed solution was introduced into a polytetrafluoroethylene-lined reaction kettle with a capacity of 100 mL, and kept at 140° C. for 48 hours to obtain a deposit. Then, the resulting sediment was washed with deionized water to neutral pH and dried at 90 °C to obtain TiO 2 Powder, the sample is marked as A.

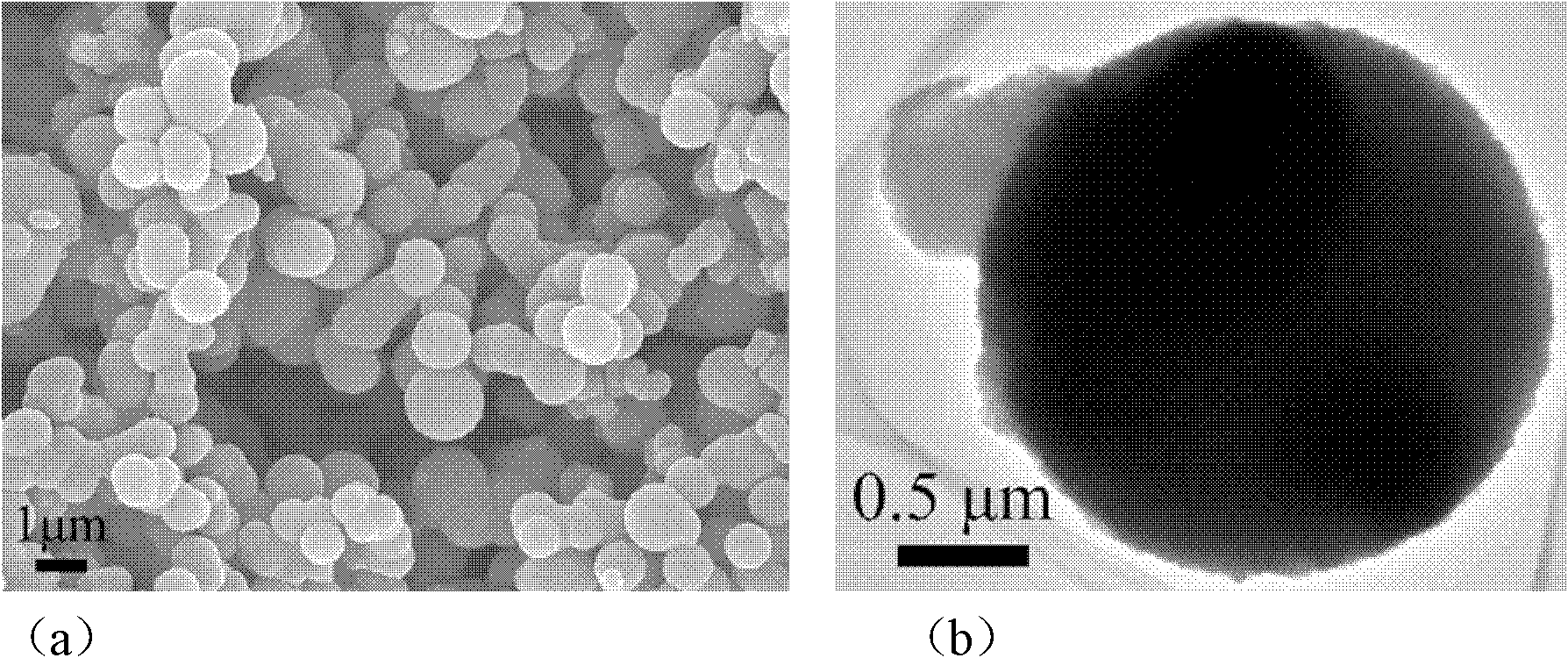

[0047] The surface morphology and structural characteristics of the sample were observed by using the S-4800 scanning electron microscope of Hitachi, Japan and the 2100 transmission electron microscope of JEOL. The results are as follows: figure 1 (a) and figure 1 As shown in (b), the results show that the obtained TiO 2 It is a solid ba...

Embodiment 2

[0051] At room temperature, under the action of magnetic stirring, 1.0g (4mmol) Ti(SO 4 ) 2 Dissolve in deionized water to form a 60mL solution, add a certain amount of commercial analytical pure HNO to it 3 And dilute to 80mL with deionized water, so that the HNO 3 with Ti(SO 4 ) 2 The molar concentration ratio was 30:1. The above mixed solution was introduced into a polytetrafluoroethylene-lined reaction kettle with a capacity of 100 mL, and kept at 180° C. for 2 hours to obtain a deposit. Then, the resulting sediment was washed with deionized water to neutral pH, and dried at 90 °C to obtain TiO 2 Powder, the sample is marked as B.

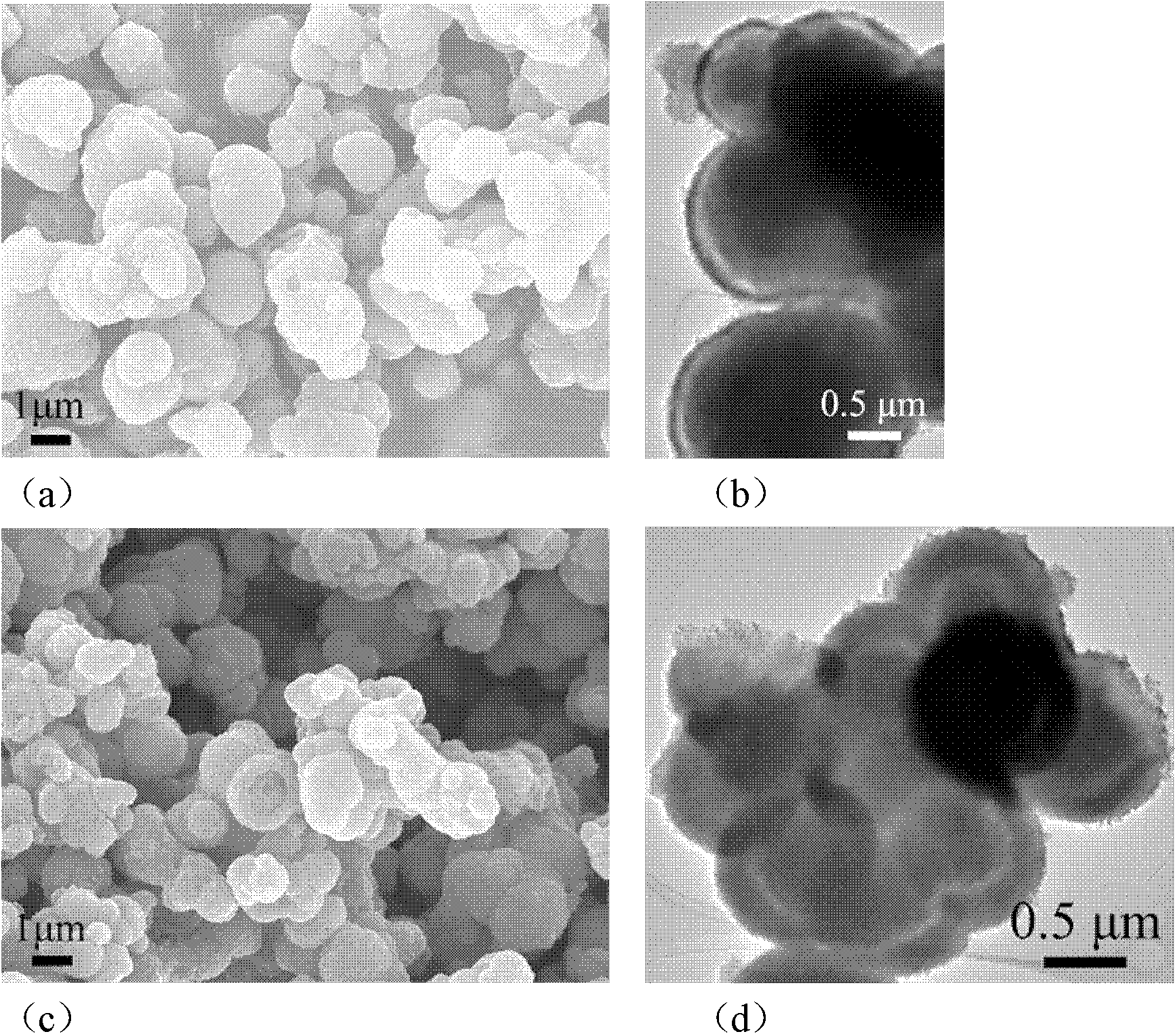

[0052] The surface morphology and structural characteristics of the sample: such as figure 2 (a) and (b) are the SEM and TEM images of sample B, respectively, and the obtained TiO 2 It is a core-shell structure, the shell is relatively thin, and the core is relatively large. The XRD analysis results show that all the diffraction peaks...

Embodiment 3

[0054] The difference from the preparation method of Example 2 is that the holding time is 5 hours, and the obtained sample is marked as C.

[0055] The surface morphology and structural characteristics of the sample: such as figure 2 (c) and (d) are the SEM and TEM images of sample C, respectively, and the obtained TiO 2 It is also a core-shell structure, and the difference from sample B obtained in Example 2 is that the shell is relatively thick and the core is relatively small. The size range of the core-shell structure of samples B and C is between 0.5-2 μm. The XRD analysis results show that all the diffraction peaks of the obtained samples belong to the anatase phase, and the grain size of the samples calculated by the Scherrer formula is shown in Table 1. The specific surface area and pore volume data of the samples are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com