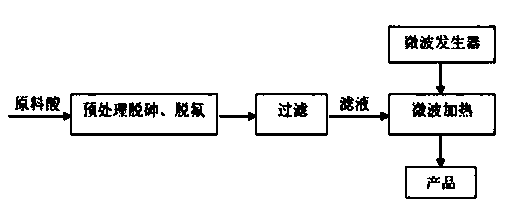

Method for preparing phosphoric acid with high density by microwave heating of fertilizer grade phosphoric acid

一种微波加热、肥料级的技术,应用在磷酸领域,能够解决磷酸含量杂质含量低、产品杂质含量高、工艺步骤复杂等问题,达到浓缩时间短、节能浓缩时间、温度低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Get 900g mass percent concentration as 30.0% (with H 3 PO 4 %) of fertilizer grade wet-process phosphoric acid, at a stirring rate of 150rpm, heat up to 90°C, add 0.27g Na 2 S, react for 0.5h, remove arsenic; under the condition of stirring rate of 200rpm, raise the temperature to 100°C, add 9g of diatomaceous earth, react for 1h, defluorinate; filter after removing arsenic and fluorine, add the filtrate to the vacuum microwave heating and concentrating device , under the condition of a vacuum of 0.08MPa, the temperature was raised to 260°C, and the heat preservation and concentration was carried out for 2 hours. After the product was lowered to room temperature, it was detected that H 3 PO 4 Content 95.5%, iron (as Fe 2 o 3 Calculated) 0.93%, aluminum (in AL 2 o 3 Calculation) 0.62%, Potassium (in K 2 O) 0.20%, calcium (CaO) 0.09%, fluorine (F) 0.18%.

Embodiment 2

[0022] Get 900g mass percent concentration as 60.0% (with H 3 PO 4 %) of fertilizer grade wet-process phosphoric acid, under the condition of stirring rate of 200rpm, heat up to 80°C, add 3.5g Na 2 S, react for 1 hour, remove arsenic; under the condition of stirring rate 150rpm, heat up to 90°C, add 4.5g of diatomaceous earth, react for 0.5h, remove fluoride; filter after removing arsenic and fluorine, add the filtrate to the vacuum microwave heating concentration In the process, under the condition of a vacuum of 0.0MPa, the temperature was raised to 260°C, and the heat preservation and concentration was carried out for 1.5h. After the product was lowered to normal temperature, it was detected that H 3 PO 4 Content 93.5%, iron (as Fe 2 o 3 Calculated) 1.42%, aluminum (in AL 2 o 3 Calculation) 0.48%, Potassium (in K 2 O) 0.17%, calcium (CaO) 0.13%, fluorine (F) 0.13%.

Embodiment 3

[0024] Get 900g mass percentage concentration to be 67.0% (with H 3 PO 4 %) of fertilizer grade wet-process phosphoric acid, under the condition of stirring rate of 100rpm, heat up to 70°C, add 4g Na 2 S, react for 1 hour, remove arsenic; under the condition of stirring rate of 100rpm, raise the temperature to 80°C, add 6g of diatomaceous earth, react for 1.5 hours, remove fluoride; , under the condition of a vacuum of 0.065MPa, the temperature was raised to 240°C, and the heat preservation and concentration was carried out for 1h. After the product was lowered to normal temperature, the H 3 PO 4 Content 98.5%, iron (as Fe 2 o 3 Calculated) 1.65%, aluminum (in AL 2 o 3 Calculation) 0.89%, Potassium (in K 2 O) 0.20%, calcium (CaO) 0.15%, fluorine (F) 0.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com