Method for detecting hollow fibrous membrane aperture performance

A fibrous membrane and fibrous technology, which is applied in the field of testing the pore size of hollow fiber membranes, can solve the problems of difficulty, inability to accurately measure gas, and inability to eliminate the error of inner surface resistance, etc., to achieve low analysis cost, objective analysis results, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The sample is a hollow fiber membrane made of polyvinylidene fluoride.

[0048] (1) Test sample production:

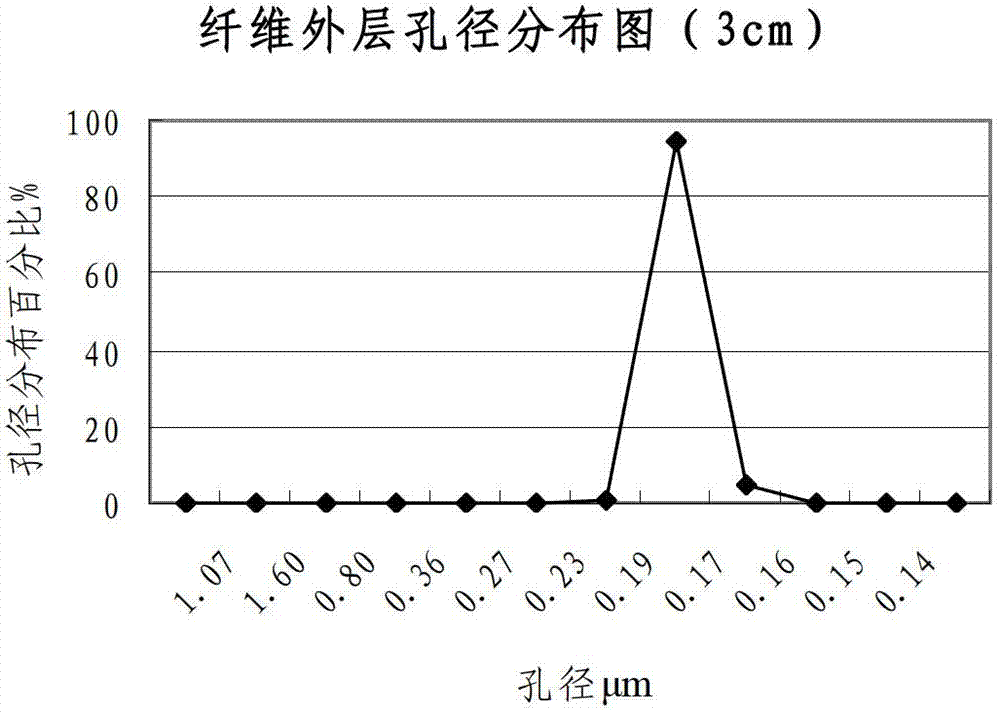

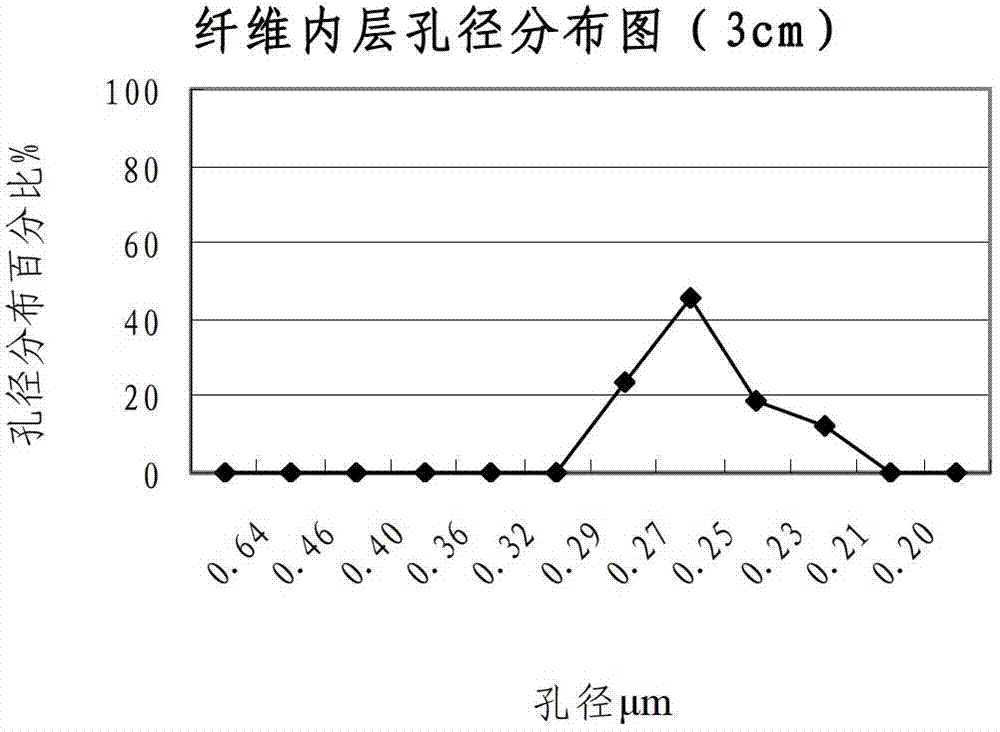

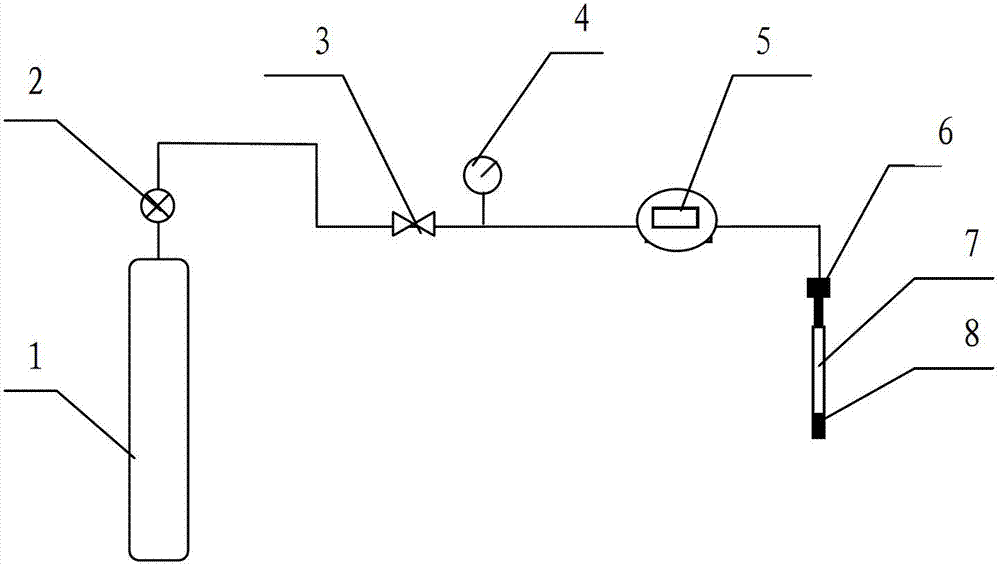

[0049] Cut out a hollow fiber membrane made of polyvinylidene fluoride with a length of 3 cm from the sample, and insert a stainless steel rod with the same size as the inner hole into the inner hole of one end of the hollow fiber membrane for sealing. The outer wall and end surface of the hollow fiber membrane must not be sealed. Or blockage, enter the inner hole of the other end of the hollow fiber membrane with an injection needle of the same size as the inner diameter, and fix the needle and the hollow fiber membrane as a channel for gas to enter the inner hole of the hollow fiber membrane. Put the above-mentioned hollow fiber membrane and the airway tube sealed at one end into the perfluoroalkane soaking liquid to fully infiltrate. The surface tension of the perfluoroalkane is 16×10 3 N / m (20°C), the contact angle with the hollow fiber membrane made of pol...

Embodiment 2

[0055] (1) Test sample production:

[0056] Cut out a hollow fiber membrane made of polyvinylidene fluoride with a length of 3 cm from the sample, and insert a stainless steel rod with the same size as the inner hole into the inner hole of one end of the hollow fiber membrane for sealing. The outer wall and end surface of the hollow fiber membrane must not be sealed. Or blockage, enter the inner hole of the other end of the hollow fiber membrane with an injection needle of the same size as the inner diameter, and fix the needle and the hollow fiber membrane as a channel for gas to enter the inner hole of the hollow fiber membrane. Put the above-mentioned hollow fiber membrane and the airway tube sealed at one end into the perfluoroalkane soaking liquid to fully infiltrate. The surface tension of the perfluoroalkane is 16×10 3 N / m (20°C), the contact angle with the hollow fiber membrane made of polyvinylidene fluoride is 0 degrees, and it has been verified by experiments that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com