Efficient heat-conversion cooking pot with bottom surface being covered by stainless steel and manufacture method of cooking pot

A technology of heat energy conversion and stainless steel, which is applied in the field of kitchen utensils, can solve the problems of insufficient increase of bottom surface area, influence of heat energy conversion, and uneven heating, etc., to achieve the effect of increasing surface area, improving heat energy conversion, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

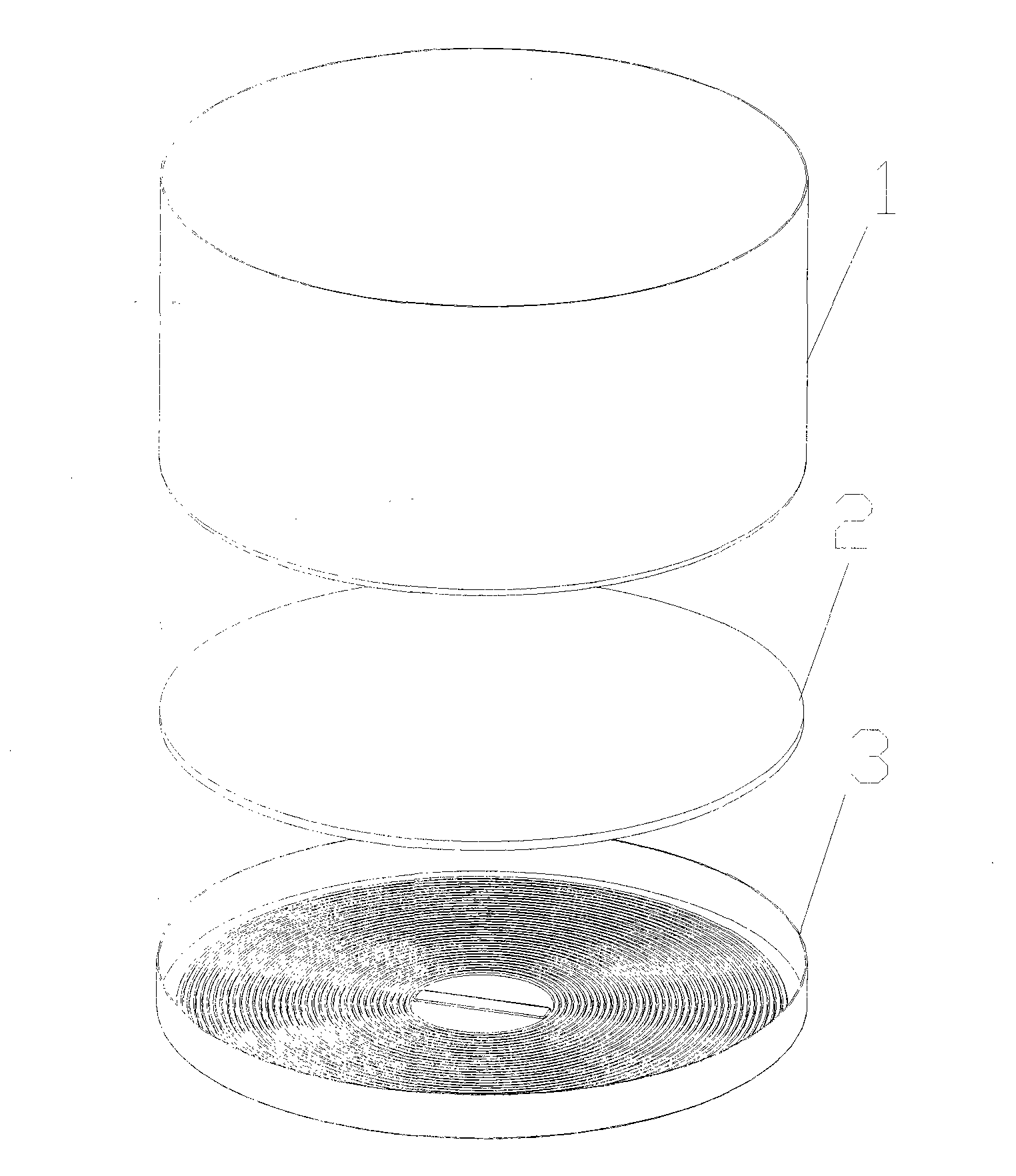

[0021] see Figure 1-Figure 4 , a high-efficiency heat energy conversion cooking stainless steel bottomed pot of the present invention is composed of a single-layer pot body 1, a bottom-covered aluminum sheet 2, and a bottom-covered stainless steel pot bottom 3, wherein the bottom-covered stainless steel pot bottom 3 has several rings of grooves 2 , the cross-section of several ring grooves 2 is a sine wave shape 3, and there is a sub-black spray coating on the outer surface of the bottom of the pot.

[0022] The process flow of sand blasting treatment and sub-black spray coating is as follows:

[0023] Workpiece → Grinding → Degreasing → Washing → Passivation → Washing → Drying → Grinding → Hanging → Soot Blowing → Primer Spraying → Topcoat Spraying → Varnish Spraying → Natural Drying → Baking → Inspection → Finished product.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com