Permanent magnet synchronous motor

A permanent magnet synchronous motor and permanent magnet technology, applied in the field of electric motors, can solve problems such as high operating temperature, fast temperature rise of permanent magnet synchronous motors, and easy demagnetization of magnetic steel, so as to increase the air intake area, good ventilation and heat dissipation conditions, and eliminate The effect of axial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

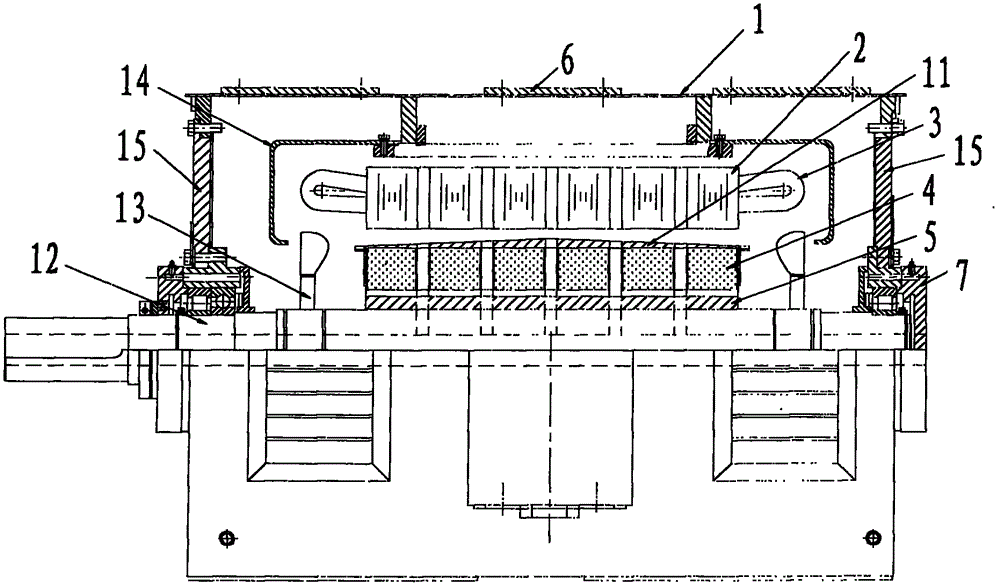

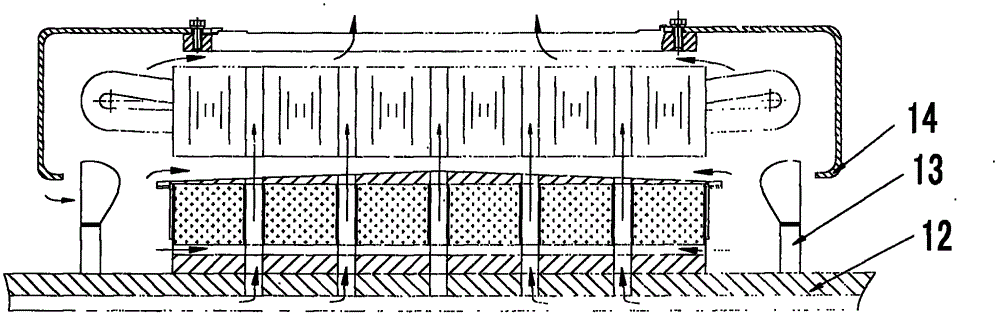

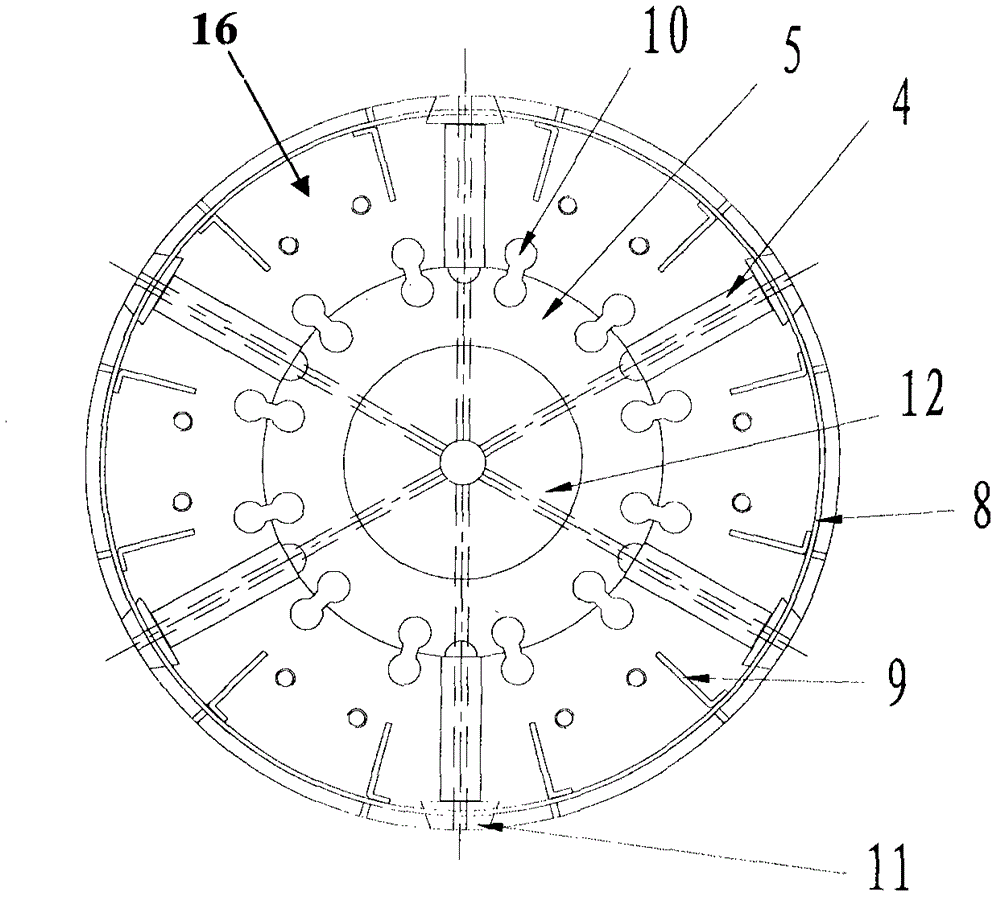

[0084] In order to improve the versatility of parts and shorten the development period and cost, the series of motors in the present invention use the stator punching plates of the Y series three-phase induction motor. The capacity is 280KW, 6KV, 6P, Y400-6 stator punching, outer diameter φ670, inner diameter φ465, iron core length L=440mm, 6 radial air passages, maximum air gap 9mm, minimum air gap 6mm, full load efficiency 94.8% , the power factor is 0.96, and the temperature rise is 71K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com