Electromagnet-permanent magnet mixed type online active balance head structure for rotary machine and control method thereof

A rotating machinery and active balancing technology, which is applied in the testing of machine/structural components, static/dynamic balancing testing, measuring devices, etc. It can solve unfavorable applicable speed and accuracy, complex structure of balancing head, large axial size, etc. problem, to achieve the effect of various counterweight methods, easy processing, and no mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

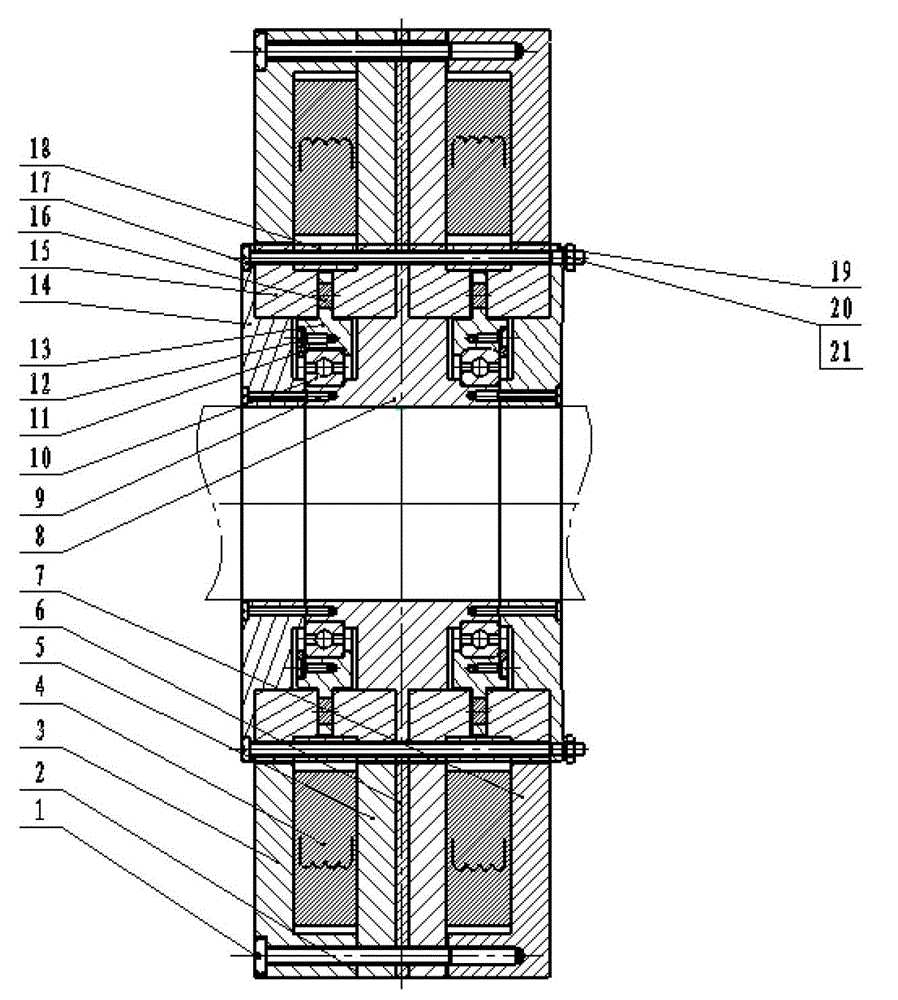

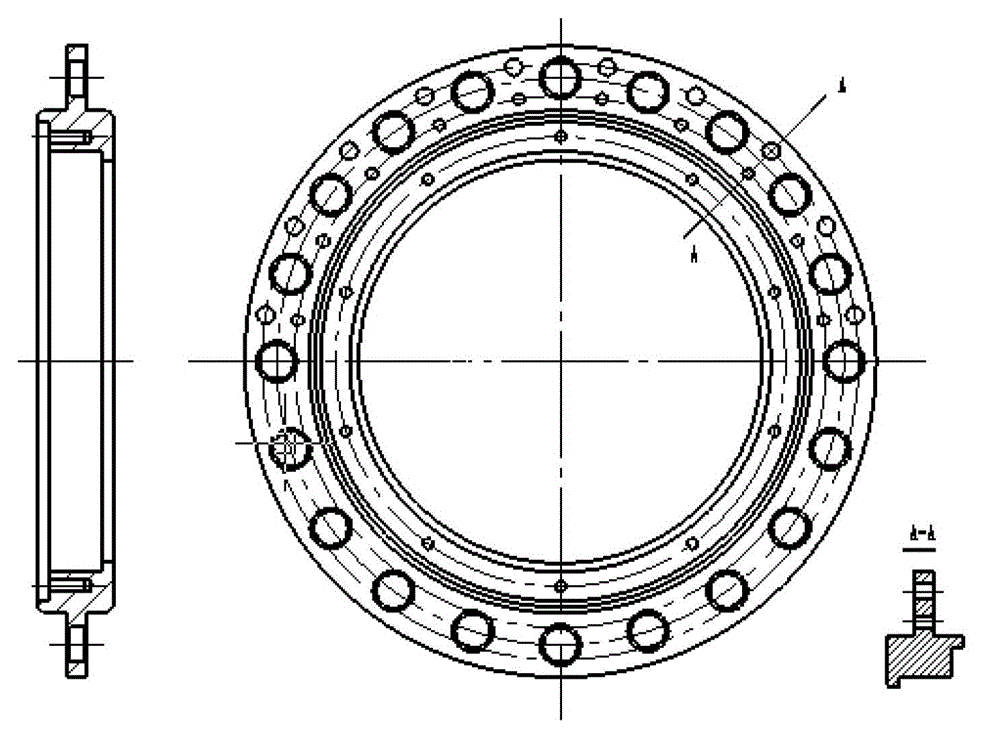

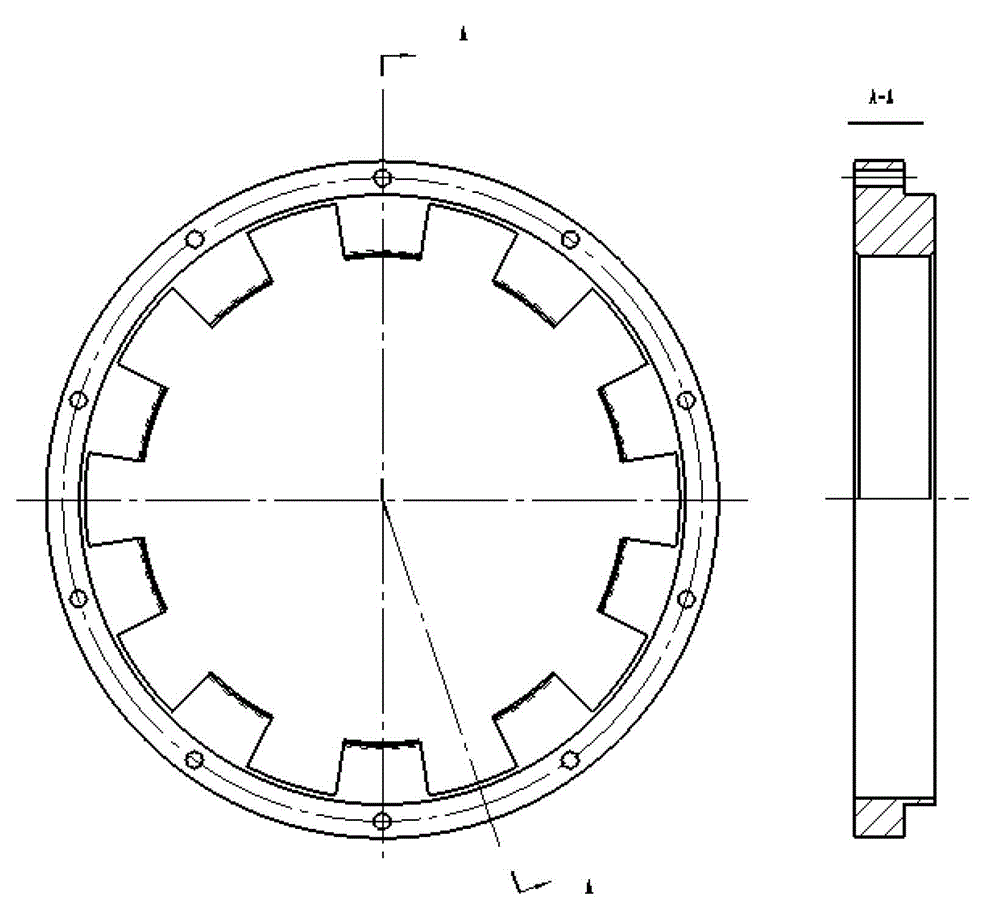

[0032] as attached figure 1 As shown, the balancing head designed by the present invention is composed of two parts: a driver (also known as stator) and an actuator (also known as rotor). In the figure, there are two sets of drivers and actuators with symmetrical structures. The driver is fixed on the stationary casing of the rotating machine and consists of iron core 3, iron core 5, coil 4 and reluctance adjustment ring 2. The actuator is installed on the rotating shaft and rotates with the shaft, and consists of a counterweight plate 13, a magnetic disc 15, a rolling bearing 10, a magnetic isolation ring 18, an end cover 19 and other parts. A working air gap of 0.4-1.5mm is designed between the driver and the actuator. When the actuator is assembled, the base is the support and center, the combination of the counterweight plate and the rolling bearing is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com