Uniform air distribution device for air chamber inlet of grate-fired furnace

A technology of air distribution device and bed combustion furnace, which is applied in the field of power engineering, can solve problems such as unfavorable coal seam stability, and achieve the effects of reducing resistance loss, reducing speed peaks, and leveling the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

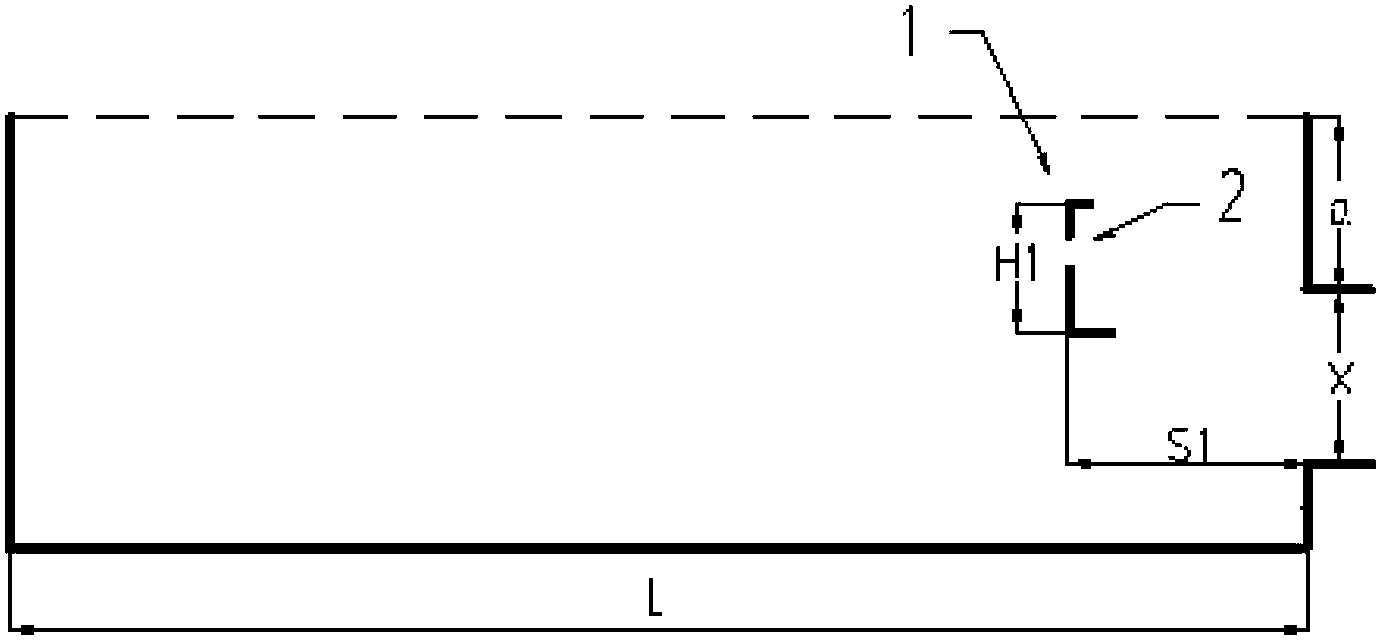

[0009] The structural principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0010] See attached figure 1 , the present invention includes a reverse "J" shaped upper partition 1 installed on the upper part of the inlet of the air chamber of the layer-burning furnace. The length of the lower straight section is 25~40mm, the angle between the upper straight section and the lower straight section of the upper partition and the horizontal line is -30°~30°, the total height of the upper partition H1=a+(0.3~0.4)x; the upper partition A "balance hole" 2 is set in the vertical part of the upper partition; the distance between the upper partition and the air inlet of the air chamber S1=(0.5~0.6)×(0.25~0.3)L; where a is the distance between the grate and the upper part of the air inlet, and x is the air inlet The height of the tuyere, L is the length of the air chamber.

[0011] In the present invention, a reverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com