Molten iron desulfurizing method and desulfurizing device thereof

A desulfurization device and a technology for desulfurization of molten iron, which are applied in the field of desulfurization of molten iron and desulfurization devices thereof, can solve the problems of reducing the effective volume of a pretreatment tank, large consumption of desulfurization agent, and high desulfurization cost, so as to reduce the desulfurization cost of molten iron, improve the desulfurization reaction efficiency, The effect of enhancing the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

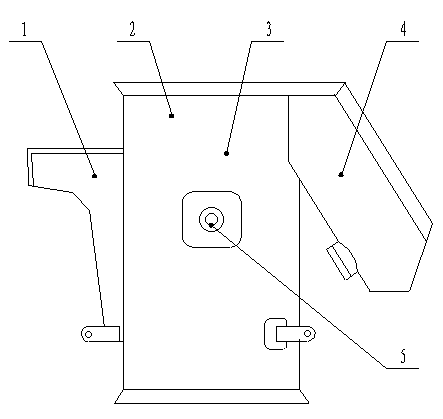

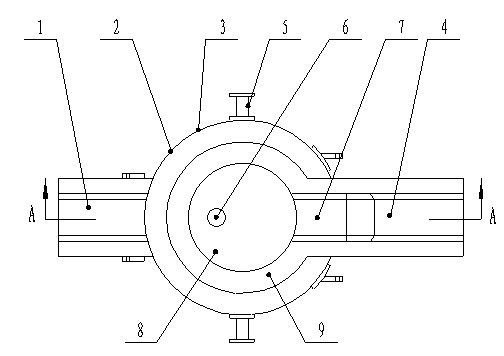

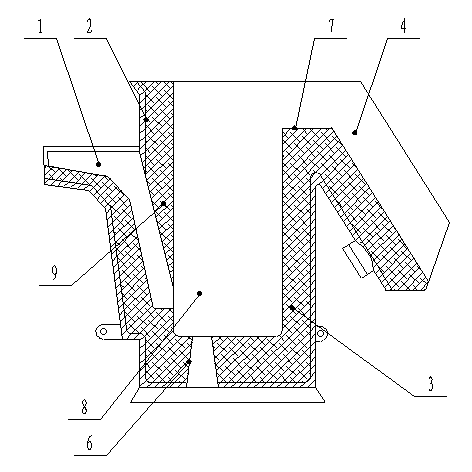

[0024] The specific implementation of the present invention will be described in detail below in conjunction with the examples and accompanying drawings, but the specific implementation of the present invention is not limited to the following examples.

[0025] Example of desulfurization method

[0026] Present embodiment is carried out in the desulfurization device of the present invention, and the volume of pretreatment tank is 1.45m 3 . The weight of molten iron to be processed is 160 tons, and the mass percentages of C, P, S and Si in the molten iron are:

[0027] C 4.0; P 0.060; S 0.24; Si 1.60;

[0028] The molten iron desulfurization method of this embodiment is to continuously flow molten iron into the inner cavity 9 of the pretreatment tank 3 of the desulfurization device. The flow rate of the molten iron is 2750 kg / min. At the same time, the composite desulfurizer of lime and fluorite is continuously added. 22kg / t molten iron; and argon is blown into the air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com