Preparation process of novel poly propylene carbonate nano-composite

A polymethyl ethylene carbonate and composite material technology, applied in the directions of carbon nanotubes, nanocarbons, carbon compounds, etc., can solve the problems of high elongation at break, poor mechanical properties, etc., and achieve low cost, easy operation, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

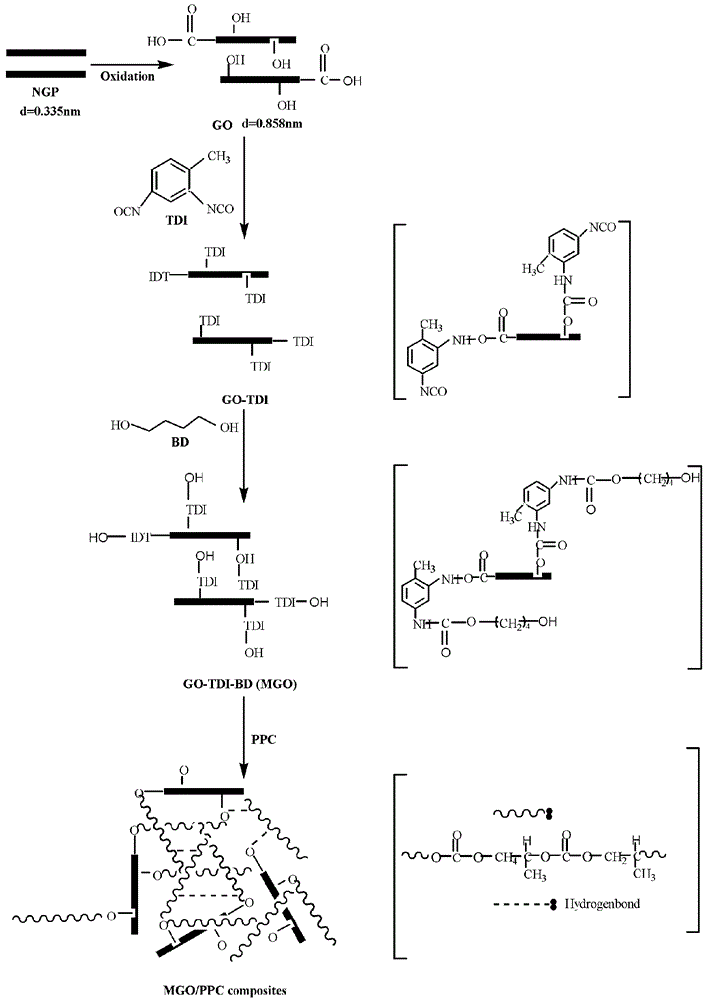

[0026] Accurately weigh 10g of natural graphite, and slowly add to it under stirring and cool to 4 o In 230mL of concentrated sulfuric acid (98%) below C, slowly add 5g of sodium nitrate and 28g of potassium permanganate, and stir for 10min. Remove the ice bath, turn the reaction system to 36 o After stirring and reacting in a hot water bath of C for 30min, then in an oil bath at 95 o C under stirring reaction 1h, the product is fully washed with 5% hydrochloric acid and deionized water, at 90 o C dried in a vacuum oven for 24 hours to obtain a graphite oxide carrier.

[0027] Accurately weigh 2g of graphite oxide and add it into a 250mL three-necked bottle containing 100mL of anhydrous DMF, and after passing through nitrogen to remove the air, ultrasonically disperse to obtain a uniform dispersion system. Then move the system to a water bath, add excess isocyanate, at 80 o C under magnetic stirring reaction 24h, then add excess butanediol at 80 o The reaction was carried...

Embodiment 2

[0031] The preparation method and functionalization method of the filler are the same as in Example 1. 0.53 g of functionalized graphite oxide filler is added to excess DMF, and after the same blending as in Example 1, a composite material with a filler content of 1% is obtained. The test conditions of the composite material are the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0033] The preparation method and functionalization method of the filler are the same as in Example 1, the filler content is 3%, and the rest of the test conditions are the same as in Example 1. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com