One-step forming machining method for threaded single tool with double wiring pipes for connecting oil well pipes

A technology for forming and processing oil country pipes, applied in thread cutting tools, metal processing equipment, thread trimmers, etc., can solve the problems of thread sticking, cumbersome, low processing efficiency, etc., to ensure sealing reliability, high dimensional accuracy, surface good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

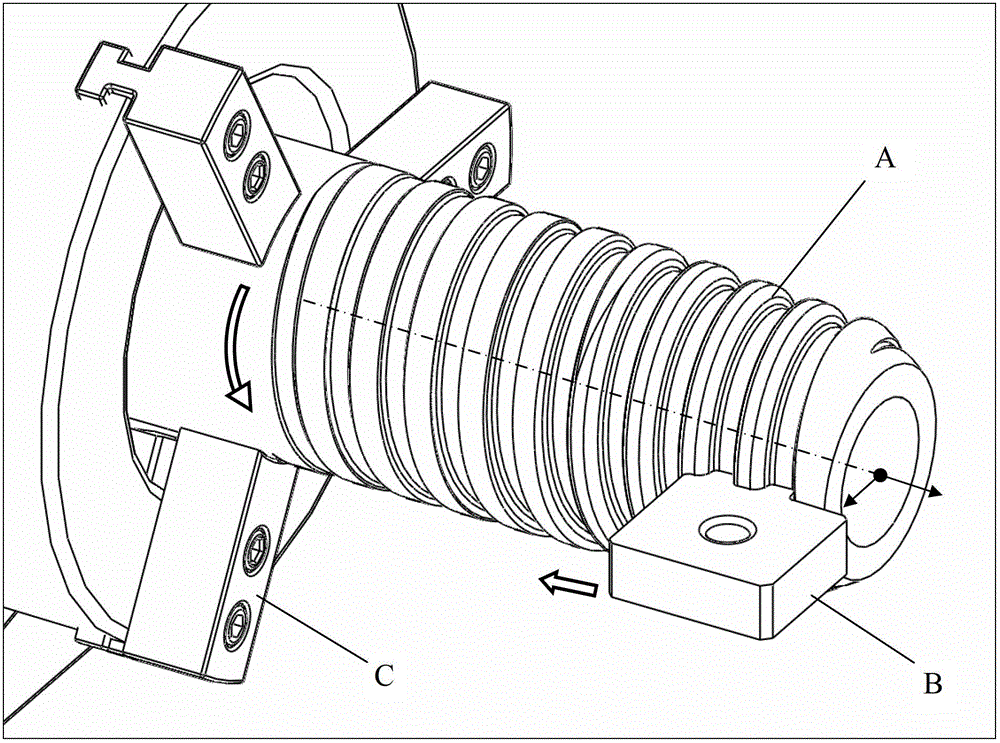

[0018] In conjunction with the accompanying drawings, the process of the single-knife one-shot forming process of the double-line pipe thread for oil well pipe connection of the present invention is described.

[0019] The theoretical basis of the present invention is the formation principle of the double thread thread, that is, the definition of the thread lead is defined as the axial distance moved by any point on the thread along the same helical line for one revolution.

[0020] The double-wire pipe thread single-knife one-time molding processing method for oil well pipe connection of the present invention includes the following steps:

[0021] On ordinary pipe threading machine tools or CNC machine tools, use a thread comb cutter B with two teeth or a number of teeth equal to an integer multiple of 2 for processing;

[0022] The parts to be processed are clamped on the jaws C of the machine tool and rotate together with the main shaft of the machine tool. The axial feed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com