Bent oscillator stimulated rotary ultrasonic motor and electric excitation mode thereof

A technology of ultrasonic motor and bending vibrator, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the vibration mode influence of motor miniaturization installation and clamping mode , high machining accuracy and assembly requirements of the cantilever part, unfavorable normal layout of the vibrator, etc., to achieve the same mode shape, increase the output speed and torque, and increase the output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

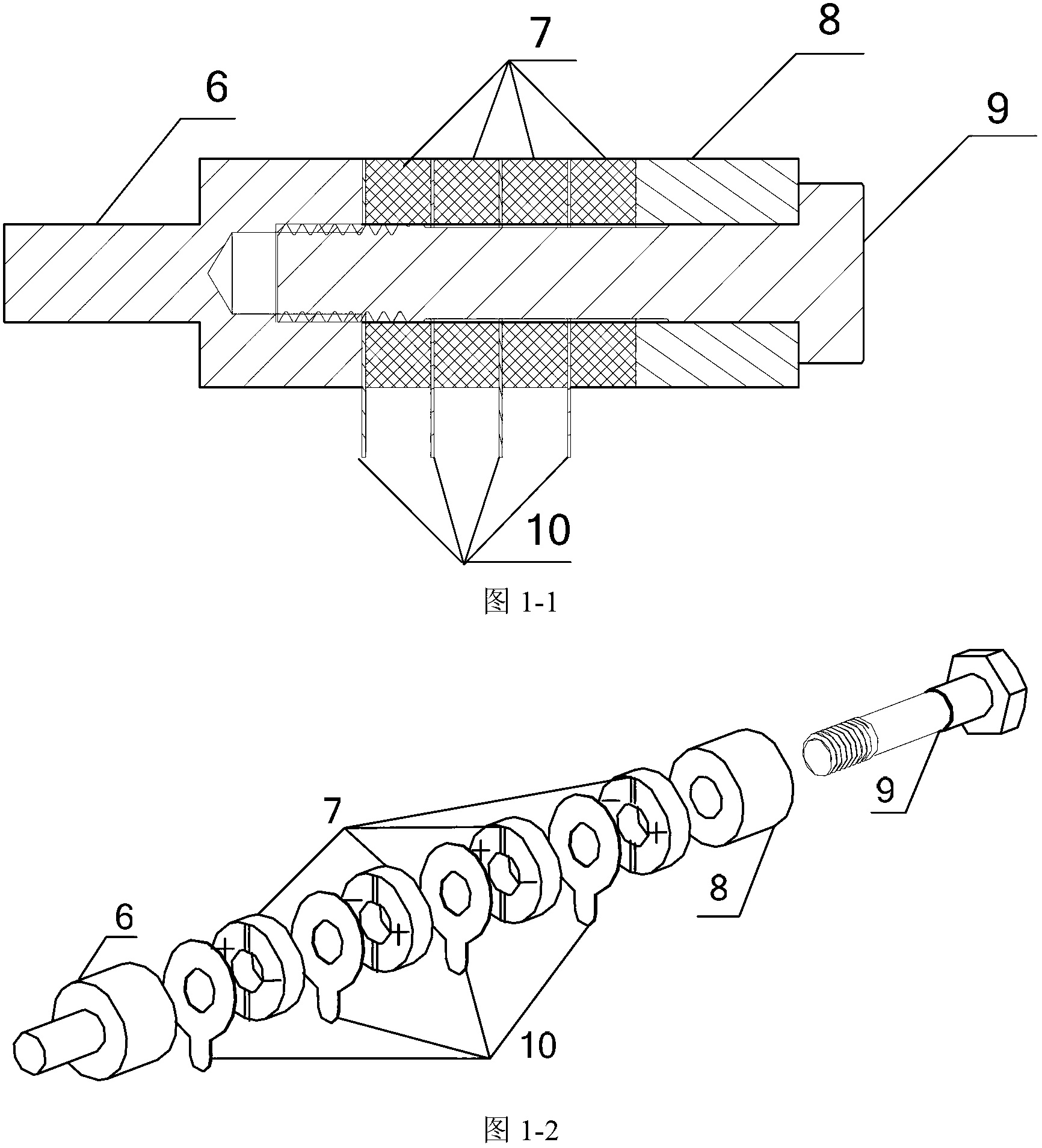

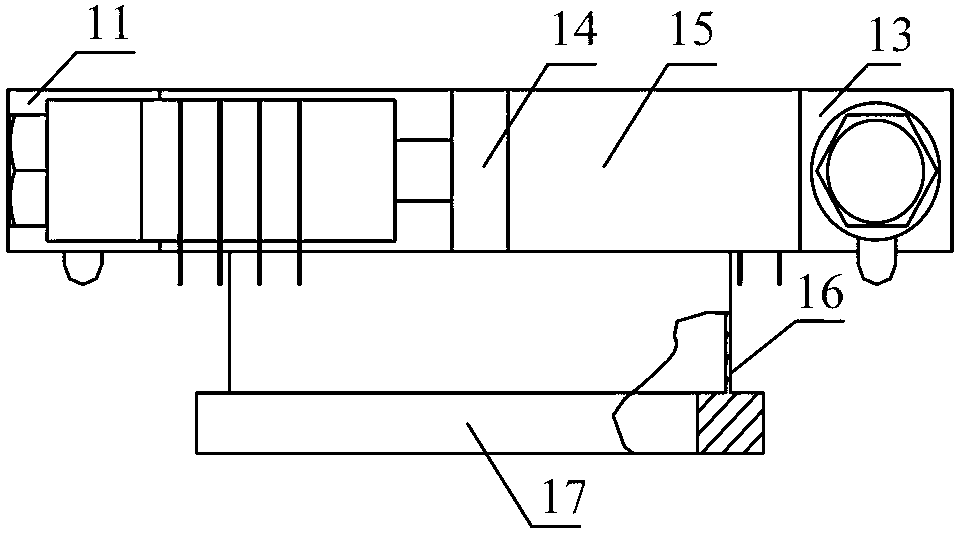

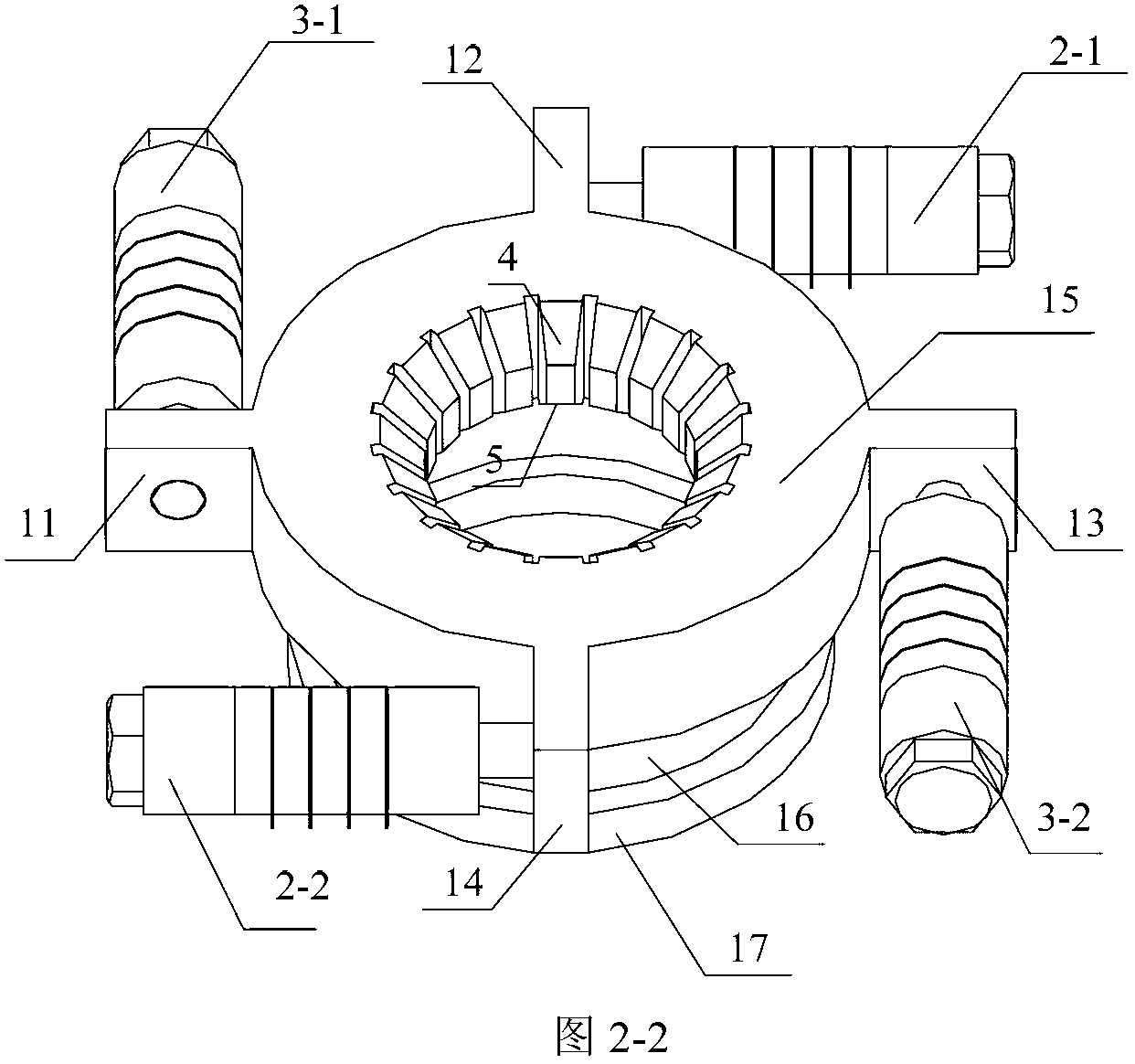

[0021] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as Figures 1 to 4 As shown, the rotating ultrasonic motor excited by the bending oscillator of the present invention includes a stator assembly, a rotor assembly, and a rotating shaft placed axially along the stator assembly, and the stator assembly and the rotor assembly are coaxially arranged; the stator assembly includes a metal ring Body and four piezoelectric bending vibrators; the metal ring body includes an upper ring, and four connecting feet are evenly distributed on the outer wall of the upper ring: the first connecting foot 11, the second connecting foot 12, and the third connecting foot 13 And the fourth connecting foot 14, the four connecting feet are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com