High CO-resistant anode catalyst of direct alcohol fuel cells and preparation and application

A fuel cell electrode, fuel cell technology, applied in fuel cell parts, battery electrodes, physical/chemical process catalysts, etc., can solve the problems of high price, scarcity of platinum-based anode catalyst resources, easy poisoning, etc., and achieve low cost. , Reduce the effect of dissolution and shedding, and reduce poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

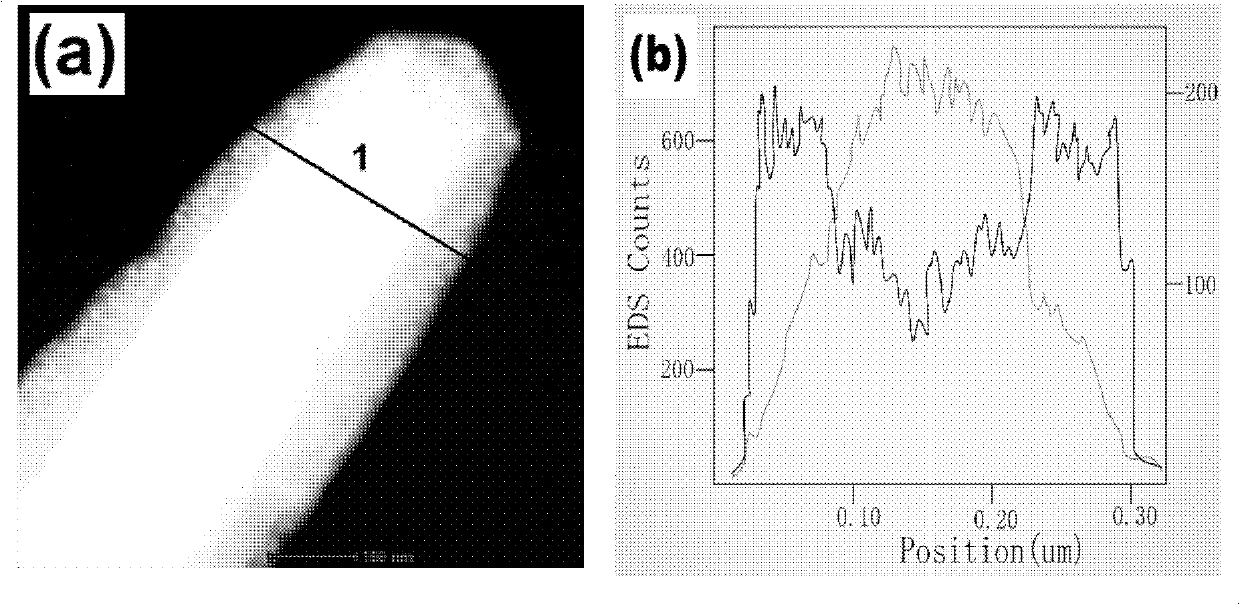

[0042] (1) Synthesis of Te dendrites: In a 50mL stainless steel autoclave lined with polytetrafluoroethylene, 0.13mmol tellurium diethyldithiocarbamate (TDEC) was dissolved in 27.6mL CHCl 3 , and then sequentially added 0.65mmol dithiosalicylic acid (DTBA) and 4.3mL NH with pH=10 3 ·H 2 O-NH 4 Cl buffer solution to 62% of the volume, the autoclave is sealed and placed in a 120°C oven. After 3 hours of reaction, the reaction solution is quenched (ice bath) to room temperature (25°C), and the two-phase interface product is centrifugally separated ( 8000rpm, 5min) to obtain a black product (precipitate), which was washed three times with high-purity water and absolute ethanol in turn, after washing, centrifuged (8000rpm, 5min) to take the precipitate and then dried in a vacuum oven at 50°C for 4 hours to obtain tellurium dendrites 15.7 mg, the yield is 94.6%. Scanning electron microscope image of tellurium dendrite see figure 1 As shown in (a) and (b), it can be seen that the...

Embodiment 2

[0045] Example 2 Preparation of highly resistant CO anode catalyst for direct ethanol fuel cell

[0046] (1) Synthesis of Te dendrites: In a 50mL stainless steel autoclave lined with polytetrafluoroethylene, 0.13mmol biphenyl ditellurium was dissolved in 27.6mL CHCl 3 , and then sequentially added 0.65mmol dithiosalicylic acid (DTBA) and 4.3mL NH at pH=10 3 ·H 2 O-NH 4 Cl buffer solution to 62% of the volume, the autoclave is sealed and placed in a 120°C oven. After 3 hours of reaction, the reaction solution is quenched (ice bath) to room temperature (25°C), and the two-phase interface product is centrifugally separated ( 8000rpm, 5min) to obtain a black product (precipitate), which was washed three times with high-purity water and absolute ethanol in turn, after washing, centrifuged (8000rpm, 5min) to take the precipitate and then dried in a vacuum oven at 50°C for 4 hours to obtain tellurium dendrites 15.2 mg, the yield is 91.6%. The structure of tellurium dendrites is c...

Embodiment 3

[0048] The preparation of embodiment 3 catalyst

[0049] (1) Synthesis of Te dendrites: In a 50mL stainless steel autoclave lined with polytetrafluoroethylene, 0.13mmol biphenyl ditellurium was dissolved in 27.6mL CHCl 3 , and then sequentially added 0.65mmol (0.117g) of glucose and 4.3mL of NH at pH=8 3 ·H 2 O-NH 4 Cl buffer solution to 62% of the volume, the autoclave was sealed and placed in an oven at 120°C. After reacting for 3 hours, it was quenched (ice bath) to room temperature (25°C). Take the two-phase interface product and centrifuge (8000rpm, 5min) to obtain a black product (precipitate), wash the precipitate with high-purity water and absolute ethanol three times in turn, and centrifuge after washing (8000rpm, 5min) to take the precipitate and put it in a vacuum oven at 50°C After drying for 4 hours, 15.2 mg of tellurium dendrites were obtained with a yield of 91.6%. The structure of the tellurium dendrites was confirmed to be the same as that of the tellurium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com