LED (light-emitting diode) packaging structure using transparent oxide substrate and packaging method thereof

A technology of transparent oxide and junction structure, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor heat dissipation, limited light output efficiency, unfavorable promotion and application, etc., to improve reliability and consistency, and improve heat dissipation Ability, the effect of improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

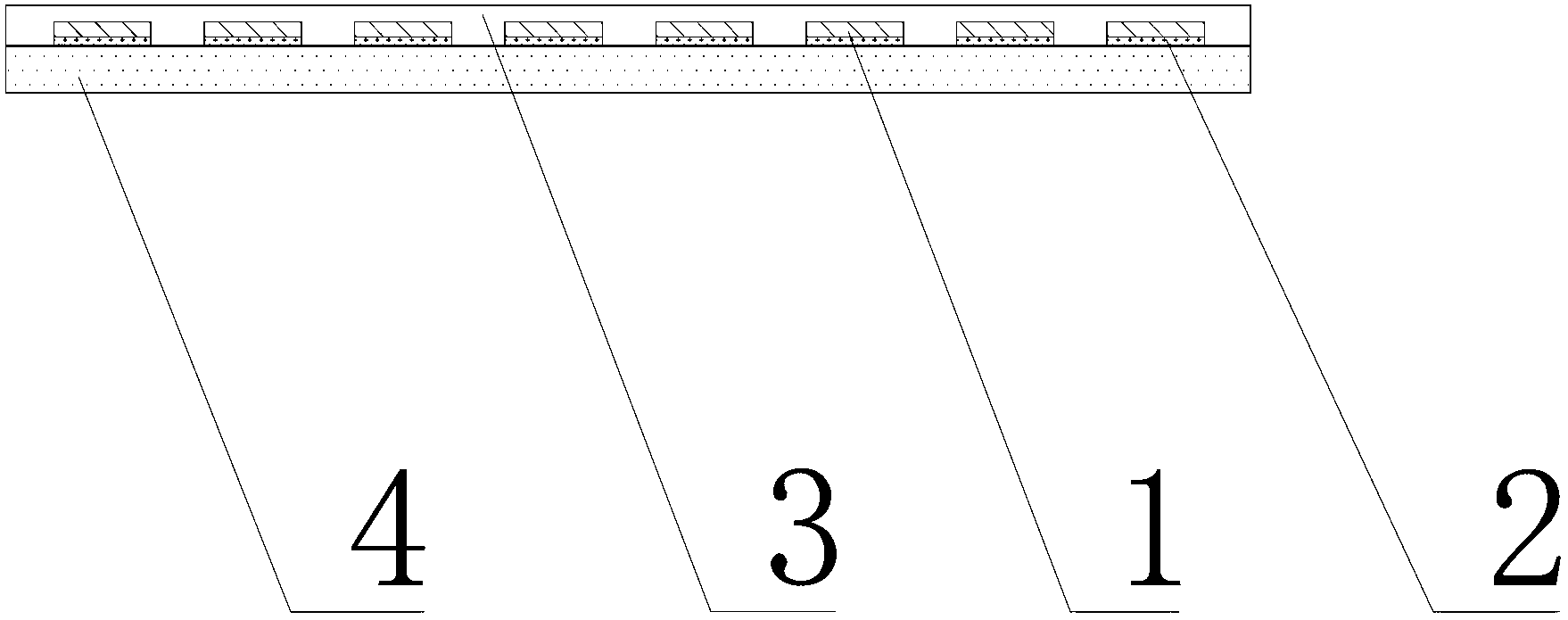

[0026] like figure 1 Shown is an LED sealing structure using a transparent oxide substrate, including a planar transparent oxide substrate 4, a fluorescent film 3 and more than one LED chip 1, and a conductive pattern 2 is arranged on the front of the transparent oxide substrate 4 , an LED bonding area is reserved on the conductive pattern 2, the LED chip 1 is arranged on the LED bonding area, the fluorescent film 3 is plastic-sealed on the front of the transparent oxide substrate 4, and the LED chip is sealed on the transparent oxide substrate 4 and the fluorescent film. Between films 3.

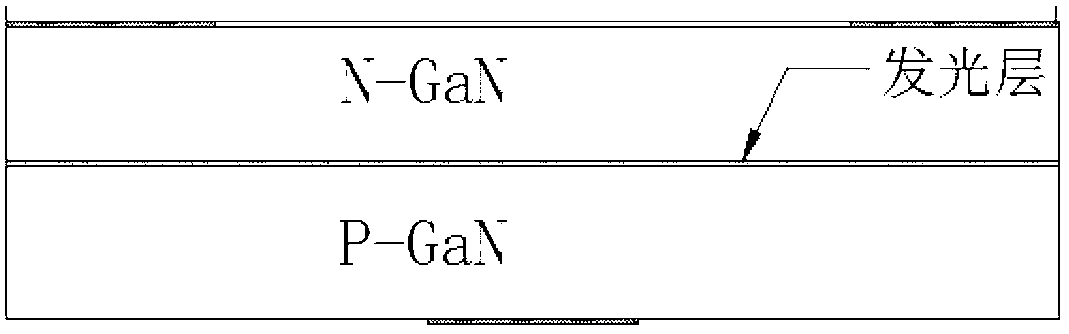

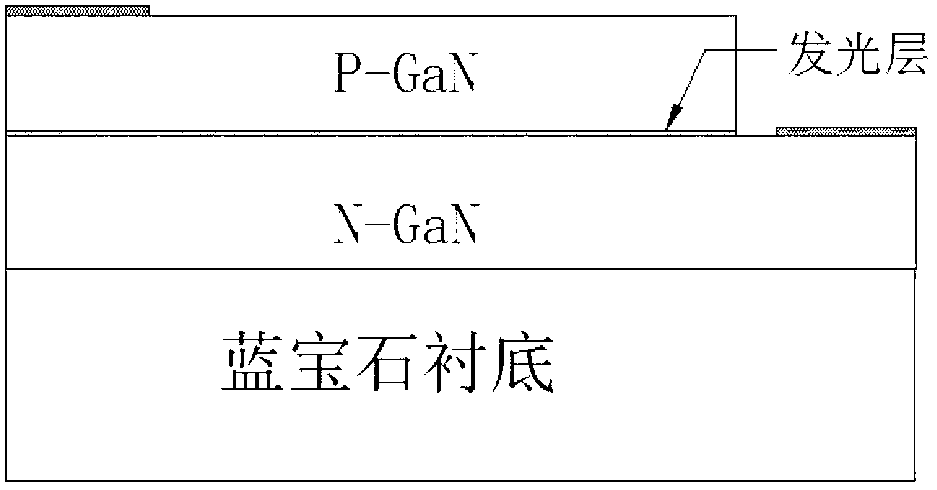

[0027] The LED chip 1 is as figure 2 Mount LED chips as shown or as image 3 The flip-chip LED chip shown; when the LED chip 1 is a front-mounted LED chip, it is connected to the conductive group 2 by jumper wiring.

[0028] The transparent oxide substrate 4 is made of yttrium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com