Scheme planning method of reconfigurable manufacturing process

A technology of manufacturing process and process plan, applied in the field of reconfigurable manufacturing process plan planning for batch processing, which can solve the problems of single special machine production line, low function utilization rate of flexible production line, difficulty in meeting product processing needs, etc., to achieve high efficiency and low cost Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

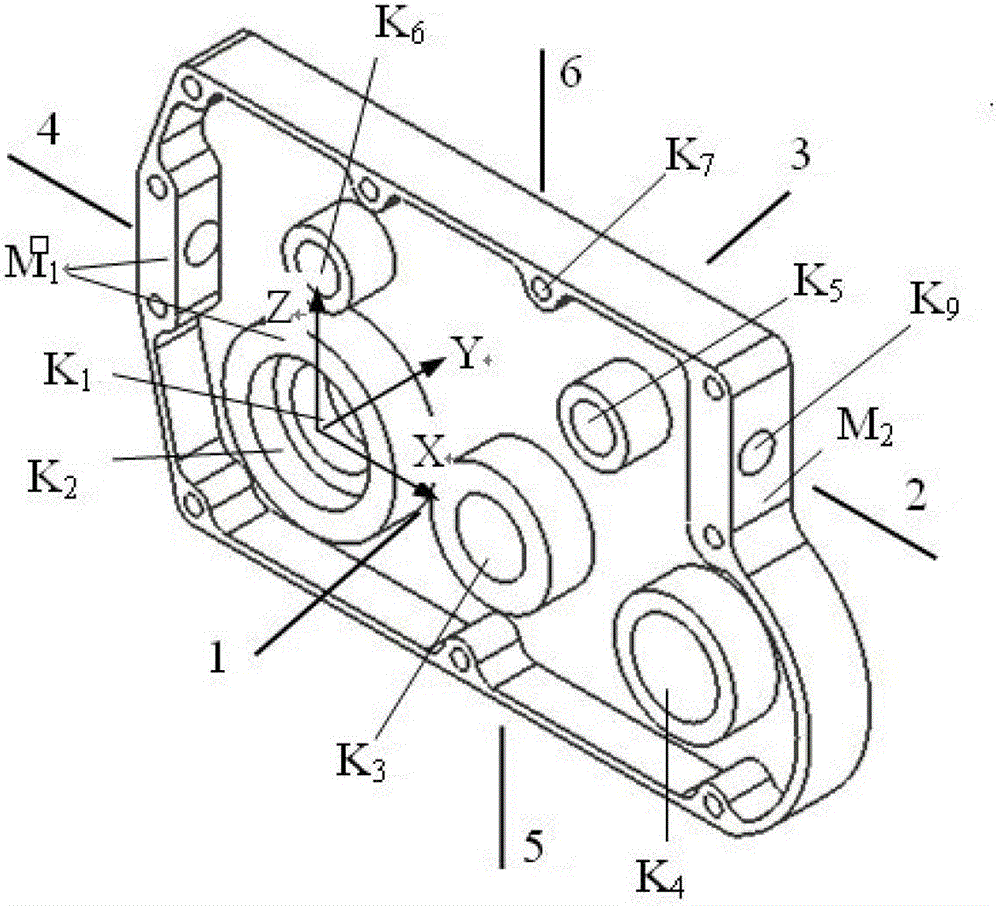

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

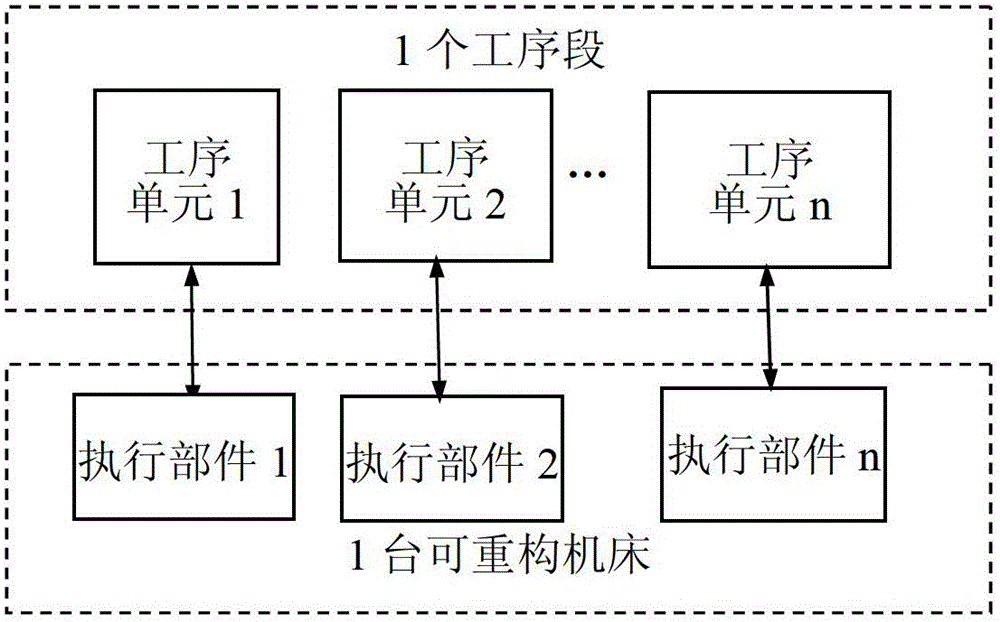

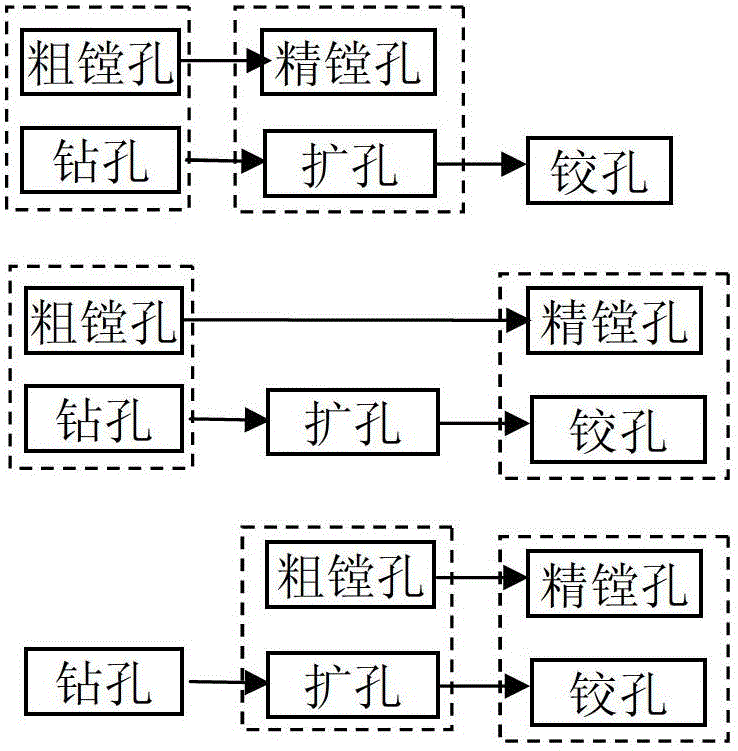

[0049] A reconfigurable manufacturing process plan planning method, based on the structural and functional characteristics of reconfigurable machine tools, the patent of the invention plans the process plan of the processed part family by establishing process units and process segments. figure 1 It is a schematic diagram of the correspondence between process units, process segments and reconfigurable machine tool execution components. A process unit corresponds to an executive component (a spindle head or a multi-axis box) on the reconfigurable machine tool, and a process segment formed by combining multiple related process units will correspond to the process content completed by a reconfigurable machine tool.

[0050] Specifically follow the steps below:

[0051] Step 1: Establish processing information matrix. The processing information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com