Filtering method for eliminating cast iron thermal analysis curve interference

A thermal analysis, curve technology, used in signal processing, steel casting fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

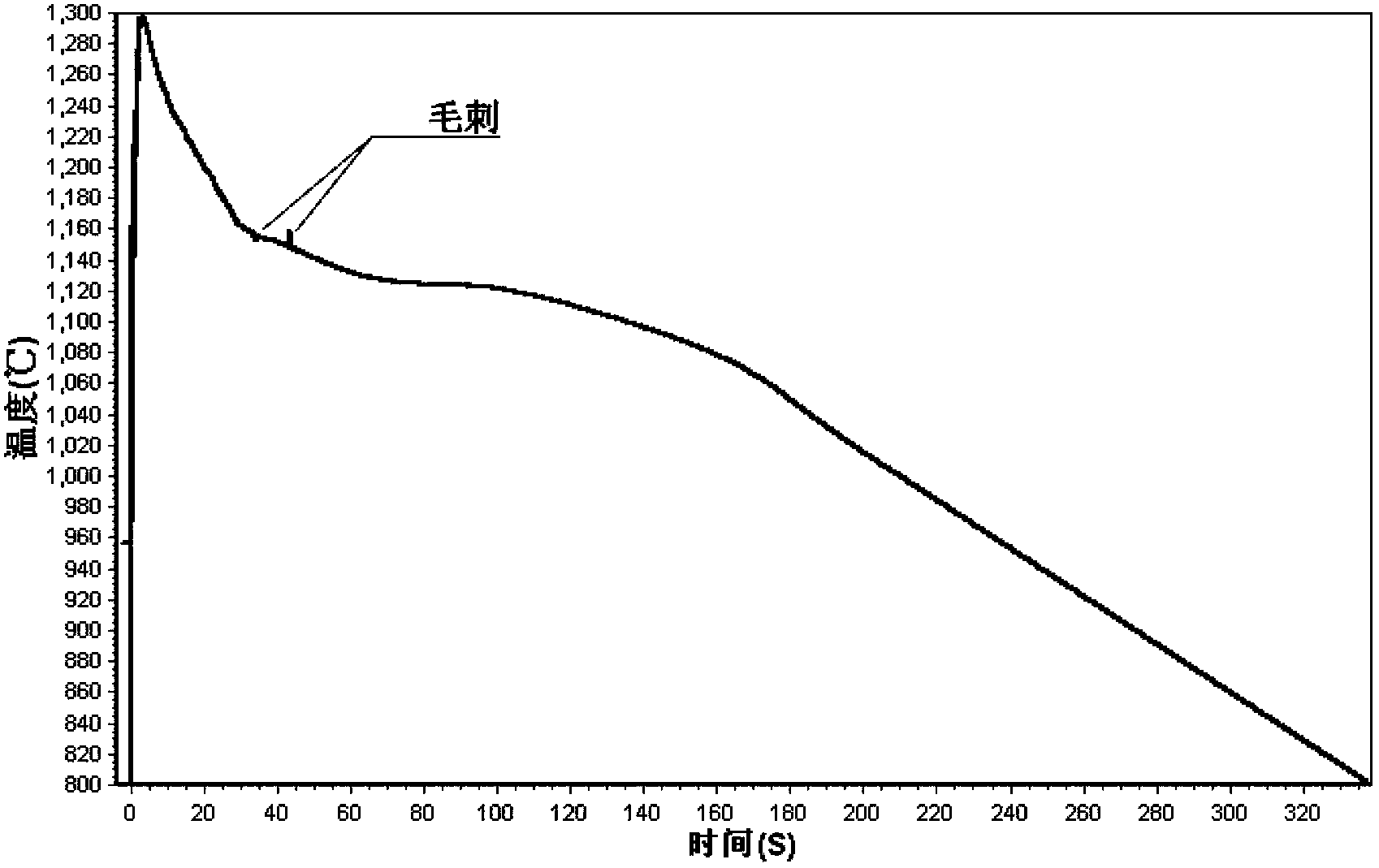

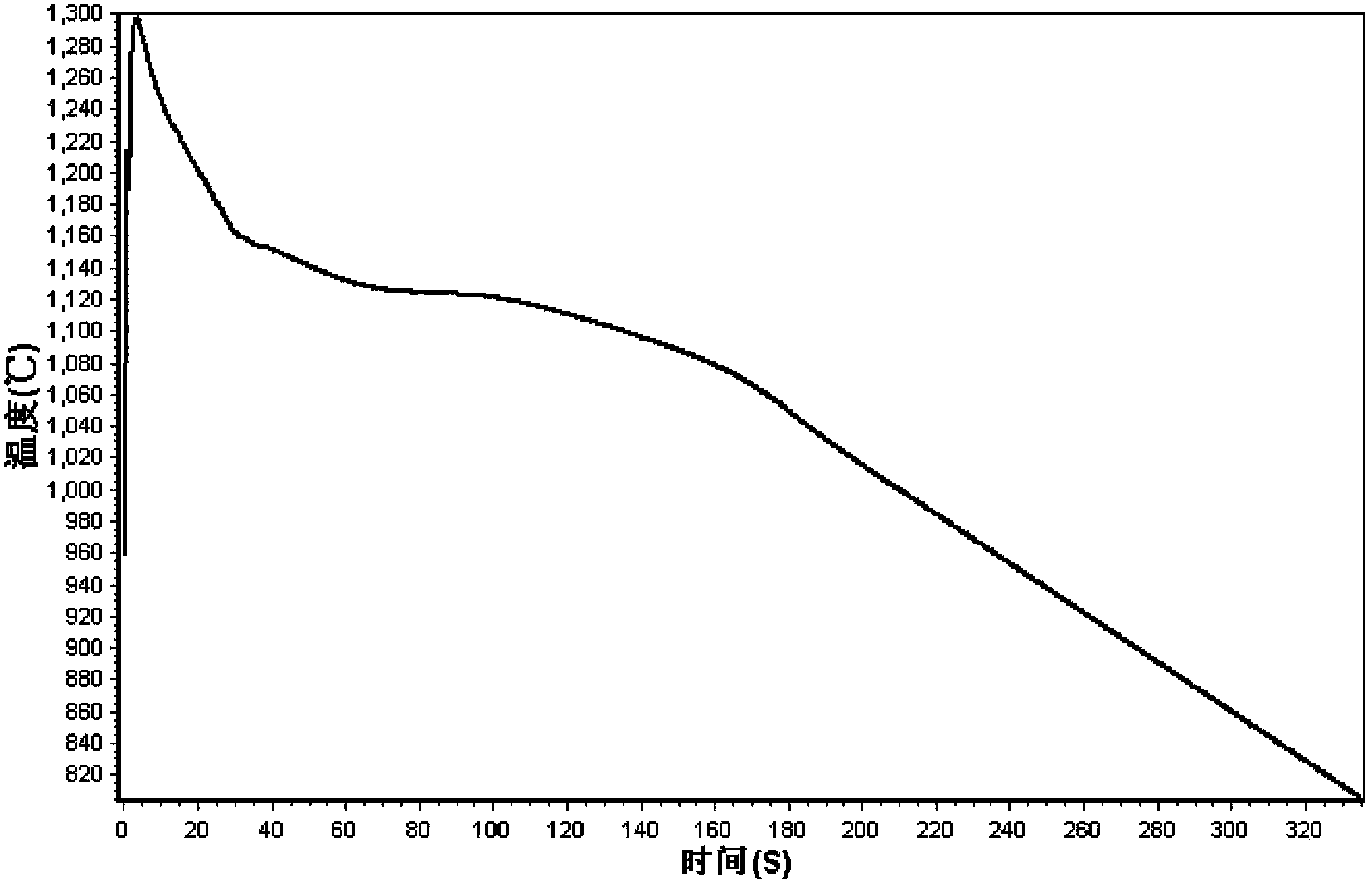

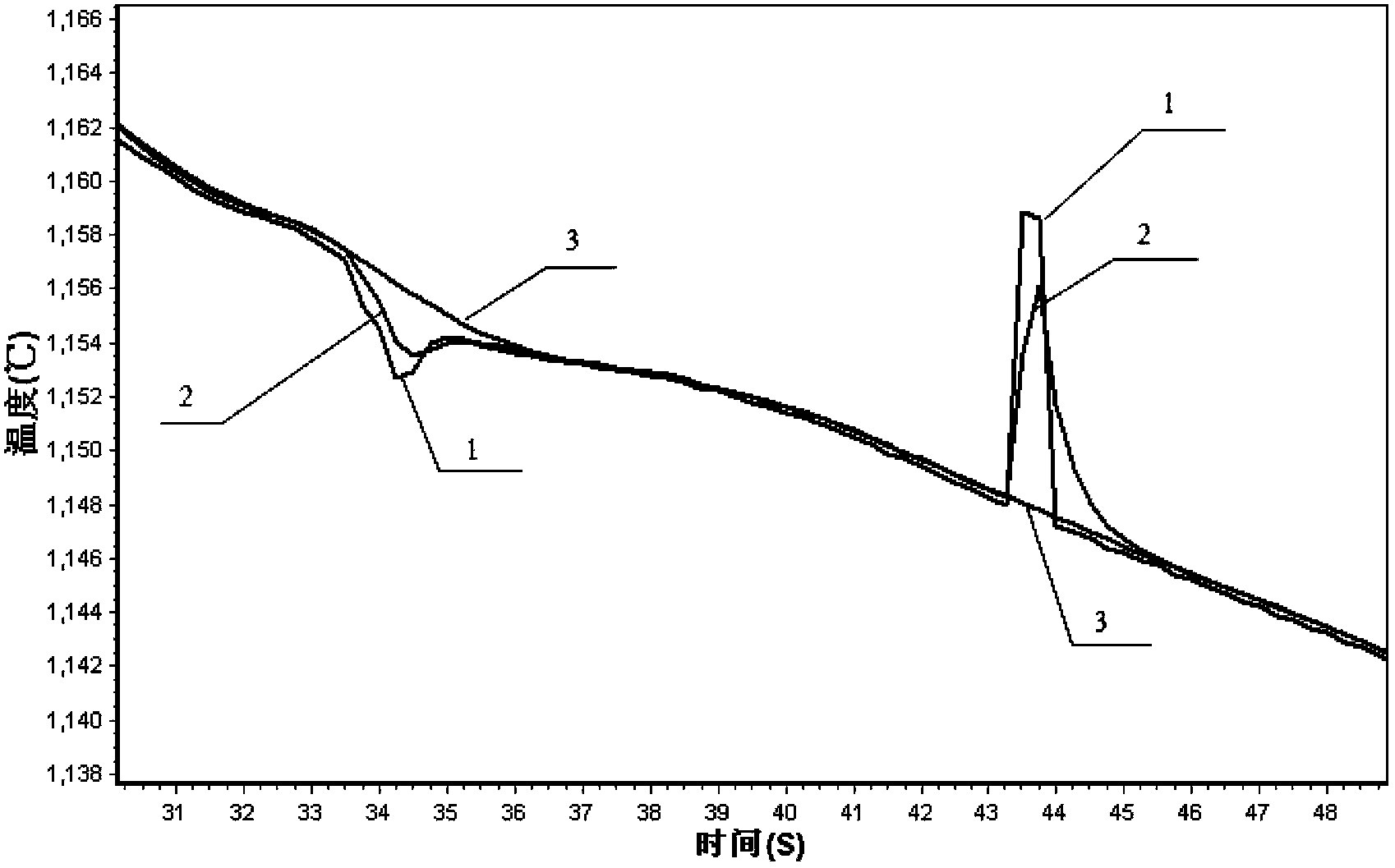

[0032]The unique filter method proposed by the invention for thermal analysis of cast iron not only removes the burrs in the curve but also retains the characteristics of severe temperature changes by separately processing the burrs and the sharp temperature change points. Improve the extraction accuracy of liquidus temperature and solidus temperature, including the following steps:

[0033] 1) Collect the cast iron temperature with a sampling period of less than 0.25 seconds;

[0034] 2) Take a continuous temperature collection point, the number is N, and the value of N is an integer from 5 to 10, and the area where the N temperature collection points are located is called the filter window, that is, the filter window is a filter window containing N temperature collection points the curve area of the point;

[0035] 3) According to the filter window parameter N and the collected temperature data, the original filter sequence {T 1 , T 2 ,... T N-1 ,T N};

[0036] 4) Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com