Iridium complex electrochemiluminescence kit for determining trace water in organic solvent

A chemiluminescence reagent and organic solvent technology, applied in the field of electrochemiluminescence kit development, can solve the problems of complex determination process, cumbersome reagent preparation, harsh preparation conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

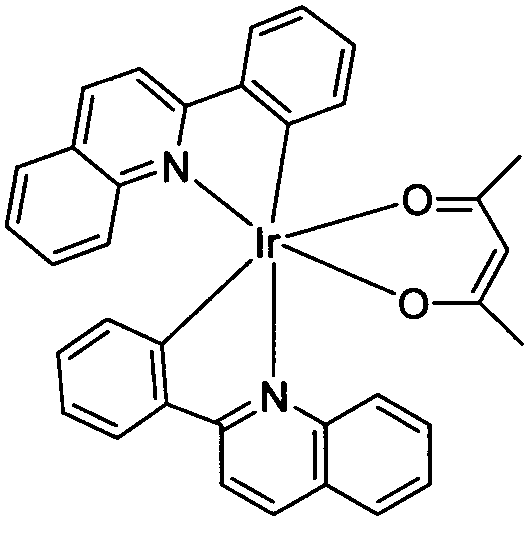

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

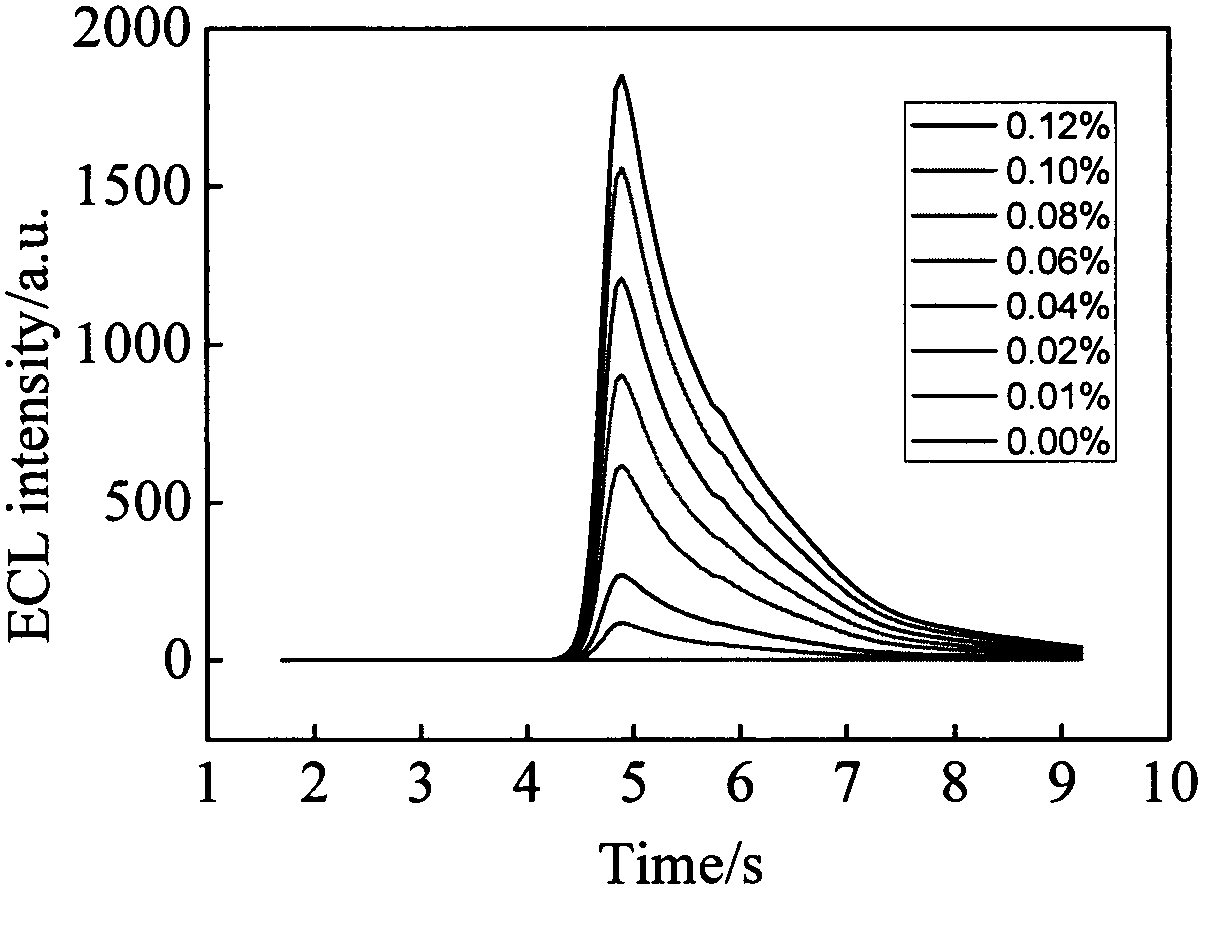

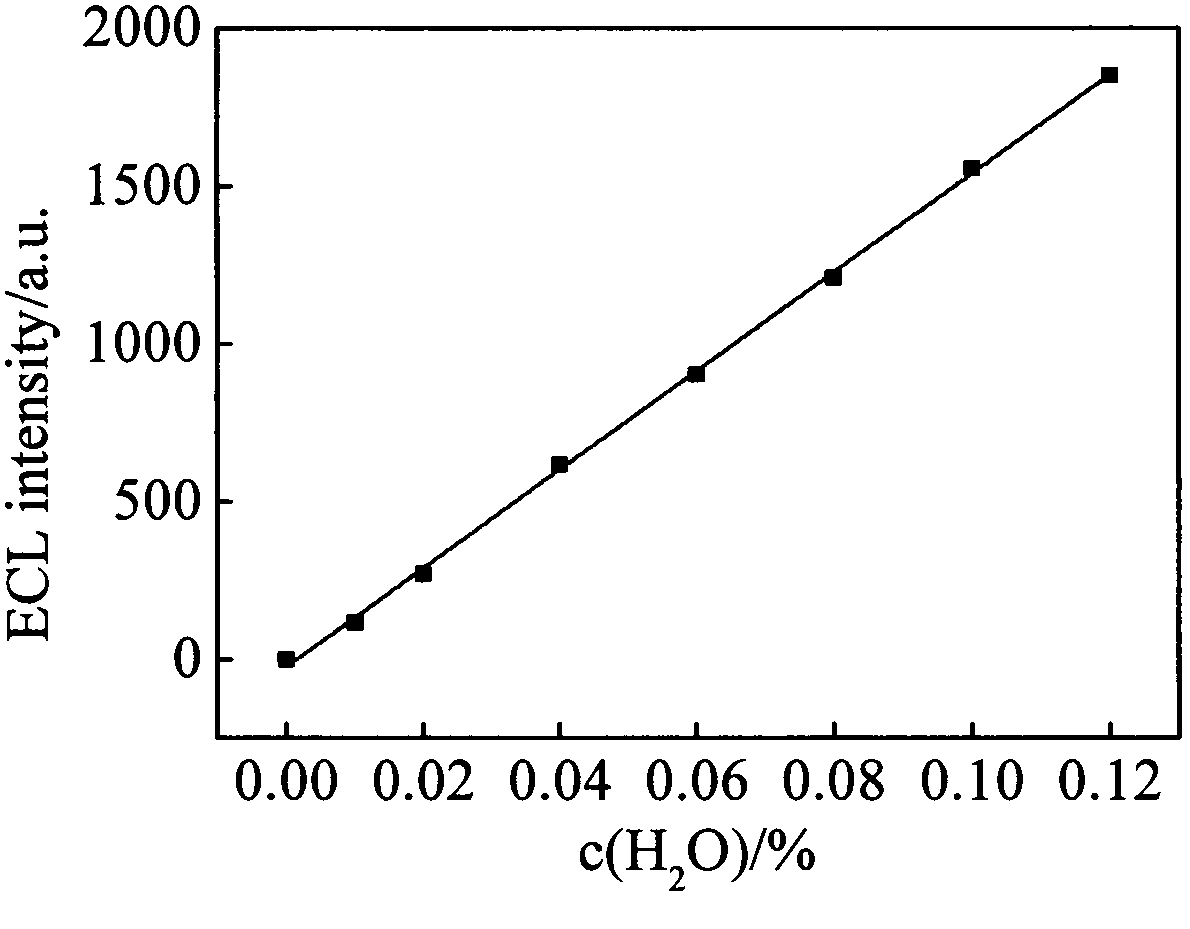

[0015] Example 1, the glassy carbon electrode is made of Al with a diameter of 0.05 μm 2 o 3 The suspension was polished on suede, then ultrasonically cleaned in absolute ethanol and ultrapure water for 1 min each, and dried in the air. Prepare a series of 3mL acetonitrile standard solutions with different water contents, the water contents from low to high are (v / v): 0.00%, 0.01%, 0.02%, 0.04%, 0.06%, 0.08%, 0.10%, 0.12%. Then completely dissolve the substances in the iridium complex electrochemiluminescence kit respectively, connect the three-electrode system to the electrochemiluminescence instrument, and measure the ECL intensity (see attached figure 2 ), with the water content as the abscissa and the ECL intensity as the ordinate to draw the working curve (see attached image 3 ). Measure the water content in the actual acetonitrile sample solvent, and find out from the working curve that the water content in the acetonitrile sample solvent is 0.023%.

example 2

[0016] Example 2, the glassy carbon electrode is made of Al with a diameter of 0.05 μm 2 o 3 The suspension was polished on suede, then ultrasonically cleaned in absolute ethanol and ultrapure water for 1 min each, and dried in the air. Prepare a series of 3mL DMF standard solutions with different water contents, the water contents from low to high are (v / v): 0.00%, 0.01%, 0.02%, 0.04%, 0.06%, 0.08%, 0.10%, 0.12%. Then completely dissolve the substances in the iridium complex electrochemiluminescence kit respectively, connect the three-electrode system to the electrochemiluminescence instrument, measure the ECL intensity, take the water content as the abscissa, and the ECL intensity as the ordinate to draw a working curve (see the appendix Figure 4 ). Measure the water content in the actual DMF sample solvent, and find out from the working curve that the water content in the DMF sample solvent is 0.064%.

example 3

[0017] Example 3, the glassy carbon electrode is made of Al with a diameter of 0.05 μm 2 o 3 The suspension was polished on suede, then ultrasonically cleaned in absolute ethanol and ultrapure water for 1 min each, and dried in the air. Prepare a series of 3 mL dichloromethane standard solutions with different water contents, the water contents from low to high are (v / v): 0.00%, 0.01%, 0.02%, 0.04%, 0.06%, 0.08%, 0.10%, 0.12 %. Then completely dissolve the substances in the iridium complex electrochemiluminescence kit respectively, connect the three-electrode system to the electrochemiluminescence instrument, measure the ECL intensity, take the water content as the abscissa, and the ECL intensity as the ordinate to draw a working curve (see the appendix Figure 5 ). Measure the water content in the actual dichloromethane sample solvent, and find out from the working curve that the water content in the dichloromethane sample solvent is 0.047%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com