High-rigid clamp of testing machine

A testing machine and high-rigidity technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of difficult alignment, changing the installation position of the curved jaws, and scrapping of the curved jaws, so as to prolong the service life. , The effect of reducing economic loss and convenient sample clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

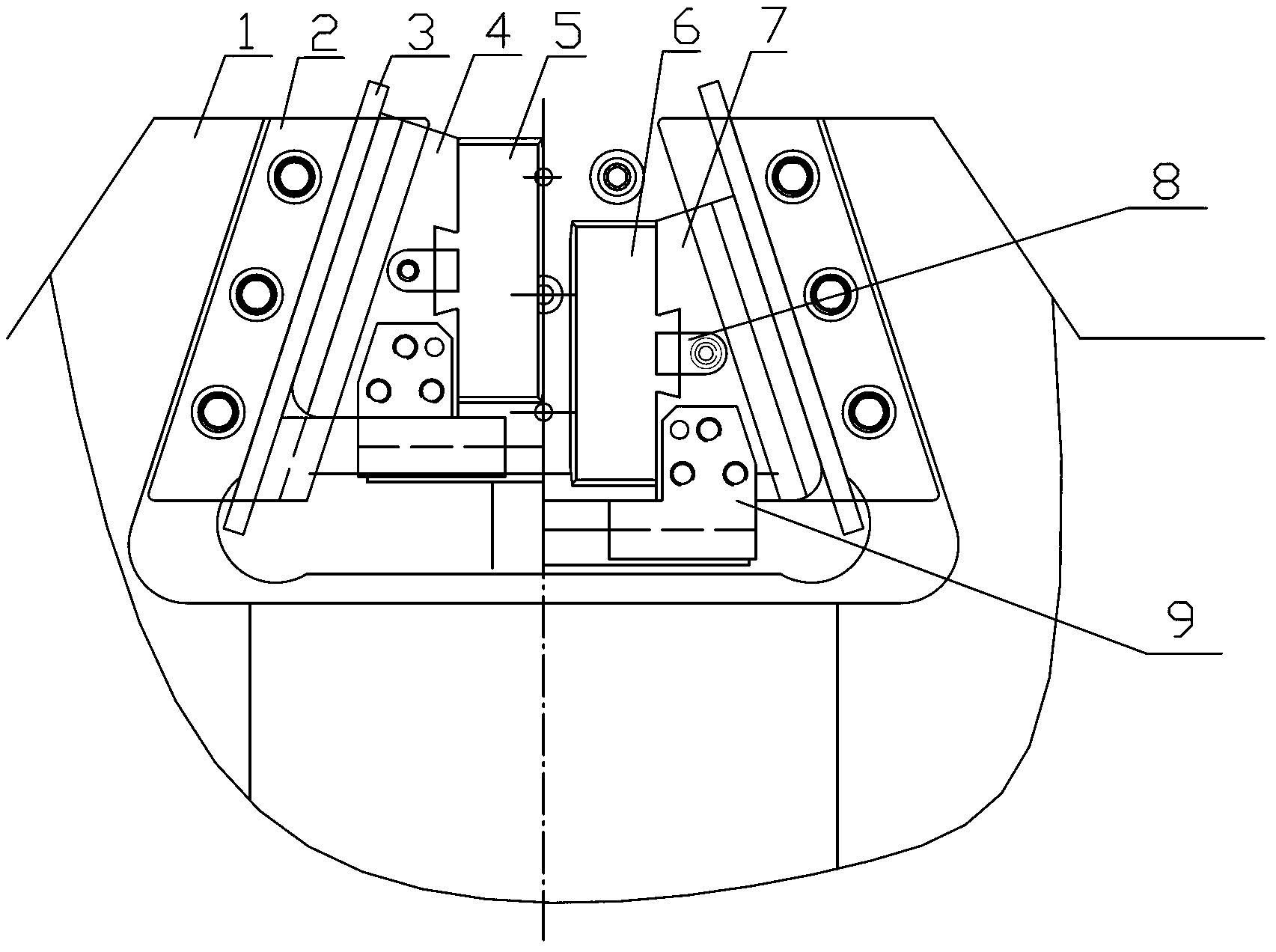

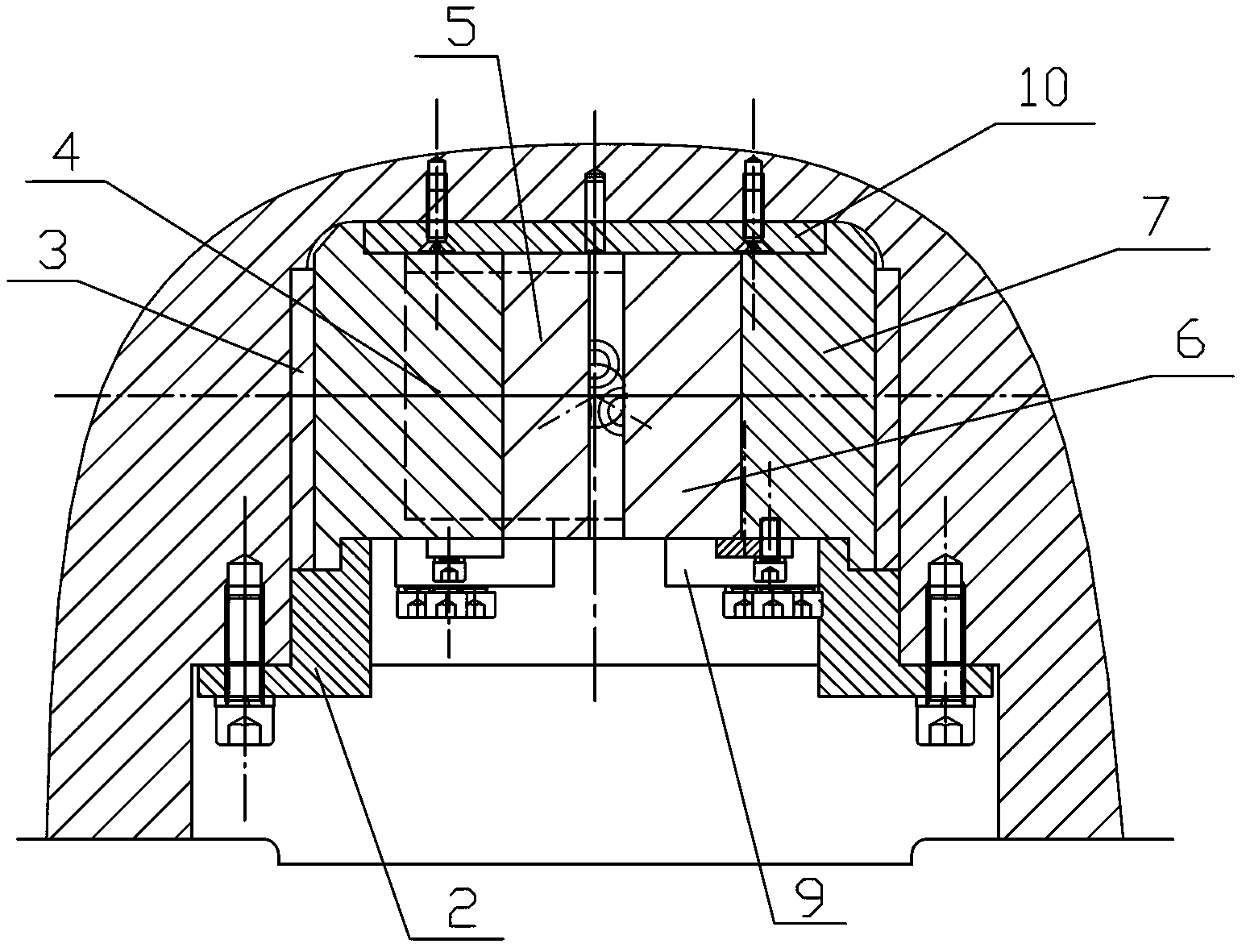

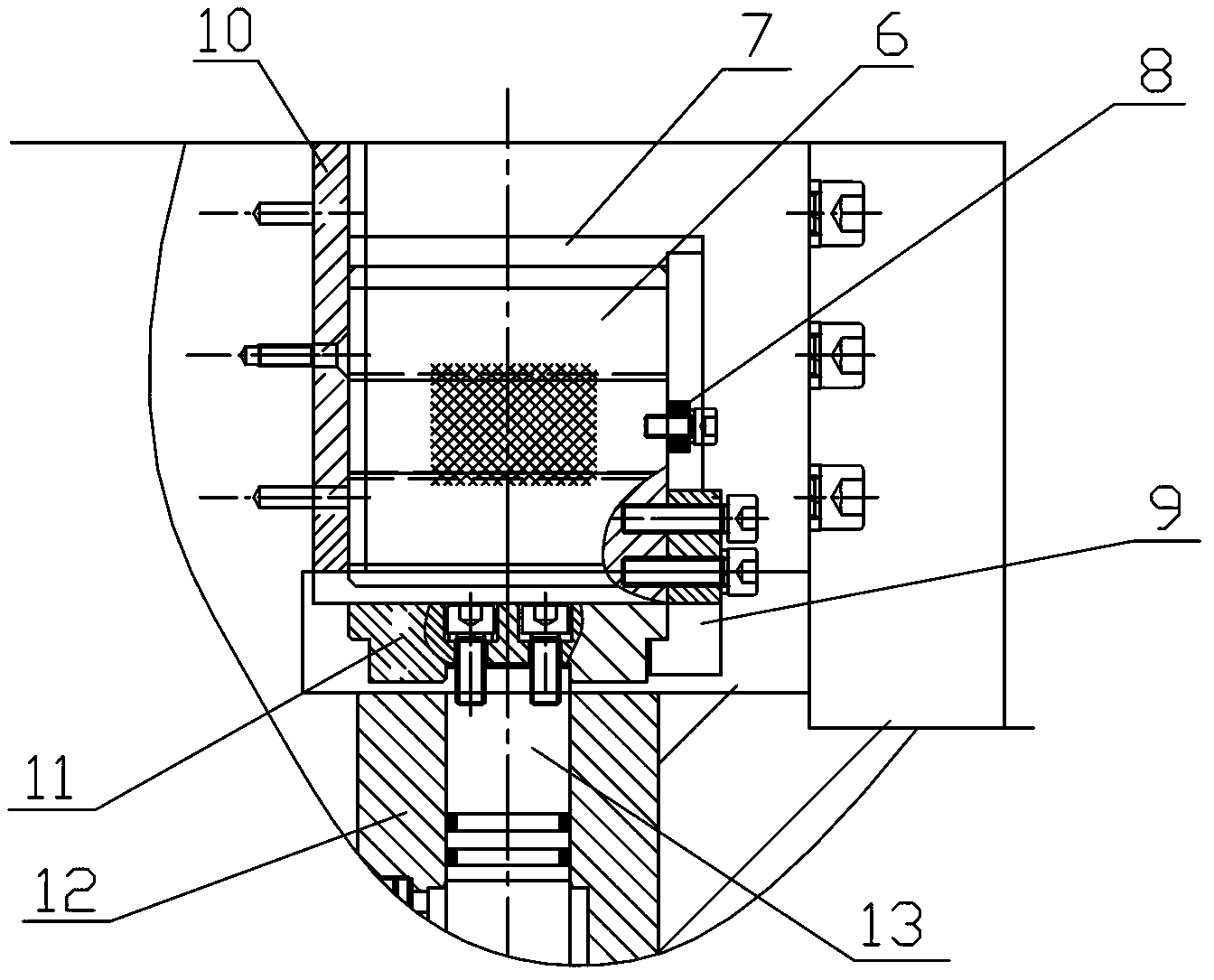

[0015] Refer to the attached figure 1 To attach Figure 7 The high-rigidity testing machine grip body of the present invention will be described in detail below.

[0016] The clamp body of the high-rigidity testing machine of the present invention has a structure comprising a jaw seat 1, a jaw clamping plate, a jaw, a push plate 11, a piston 13 and an oil cylinder 12, and the jaws include a left jaw 5 and a right jaw 6 , the jaw clamping plate includes a left jaw clamping plate 4 and a right jaw clamping plate 7, the oil cylinder 12 is arranged on the bottom of the push plate 11, and the piston 13 in the oil cylinder 12 is connected with the push plate 11 by screws, The jaw seat 1 is a semi-open jaw seat, the jaws are in the same size as the jaw clamping plate, the gap between the left jaw 5 and the left jaw clamping plate 4 and between the right jaw 6 and the right jaw The dovetail type fit is respectively adopted between the jaw clamping plates 7, and the described push pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com