Motor test system and control method for electric vehicle

A technology for electric vehicle and motor testing, which is used in motor generator testing, engine testing, and machine/structural component testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

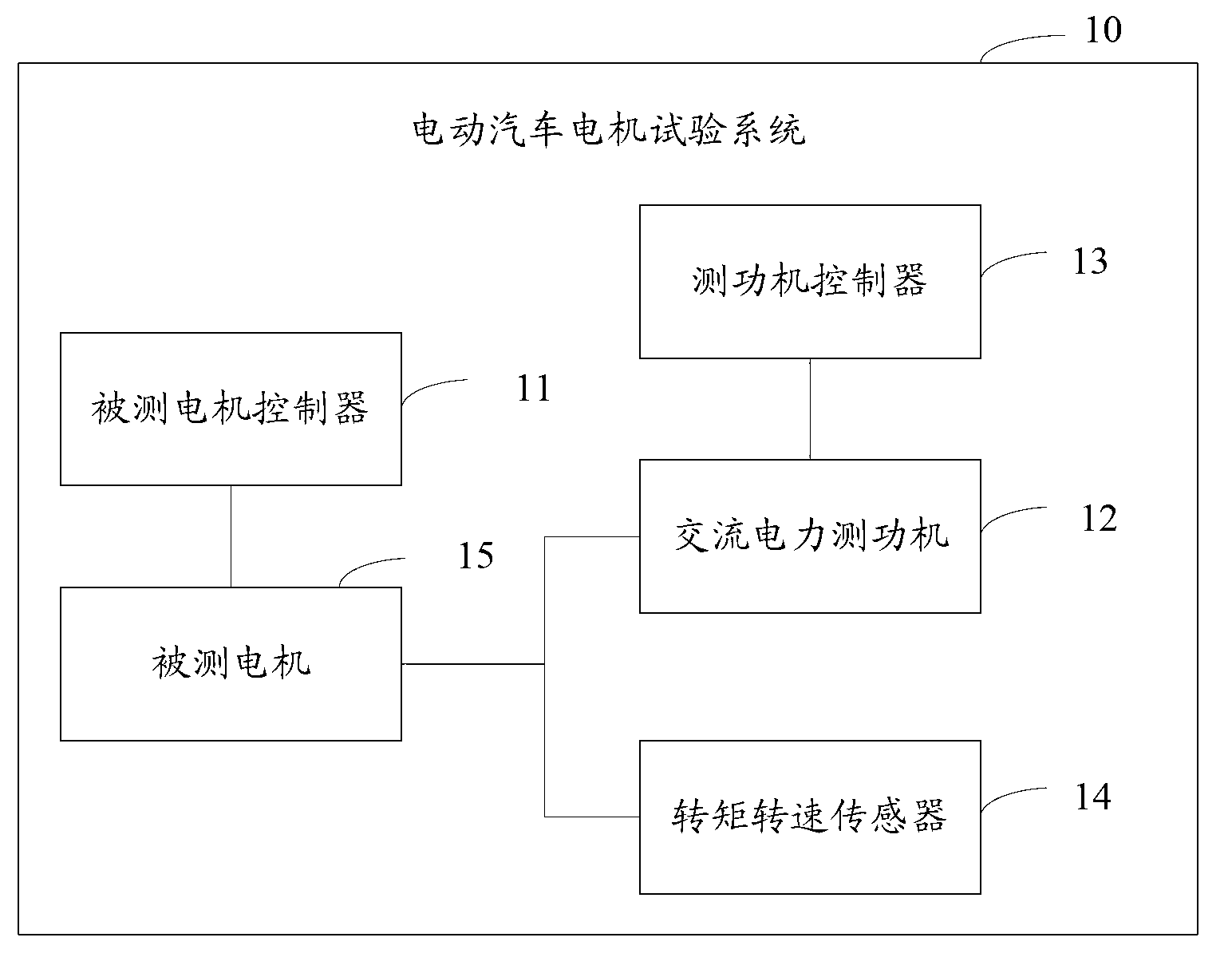

[0039] The difference between the electric vehicle motor test system of this embodiment and the electric vehicle motor test system in the above-mentioned embodiment 1 is that the system of this embodiment also includes a rectifier power supply with a feeder and an energy consumption unit, due to the addition of these two components, the system of this embodiment can realize the feed test of electric vehicle motor. Moreover, this embodiment describes other components included in the electric vehicle motor test system in addition to the components included in Embodiment 1.

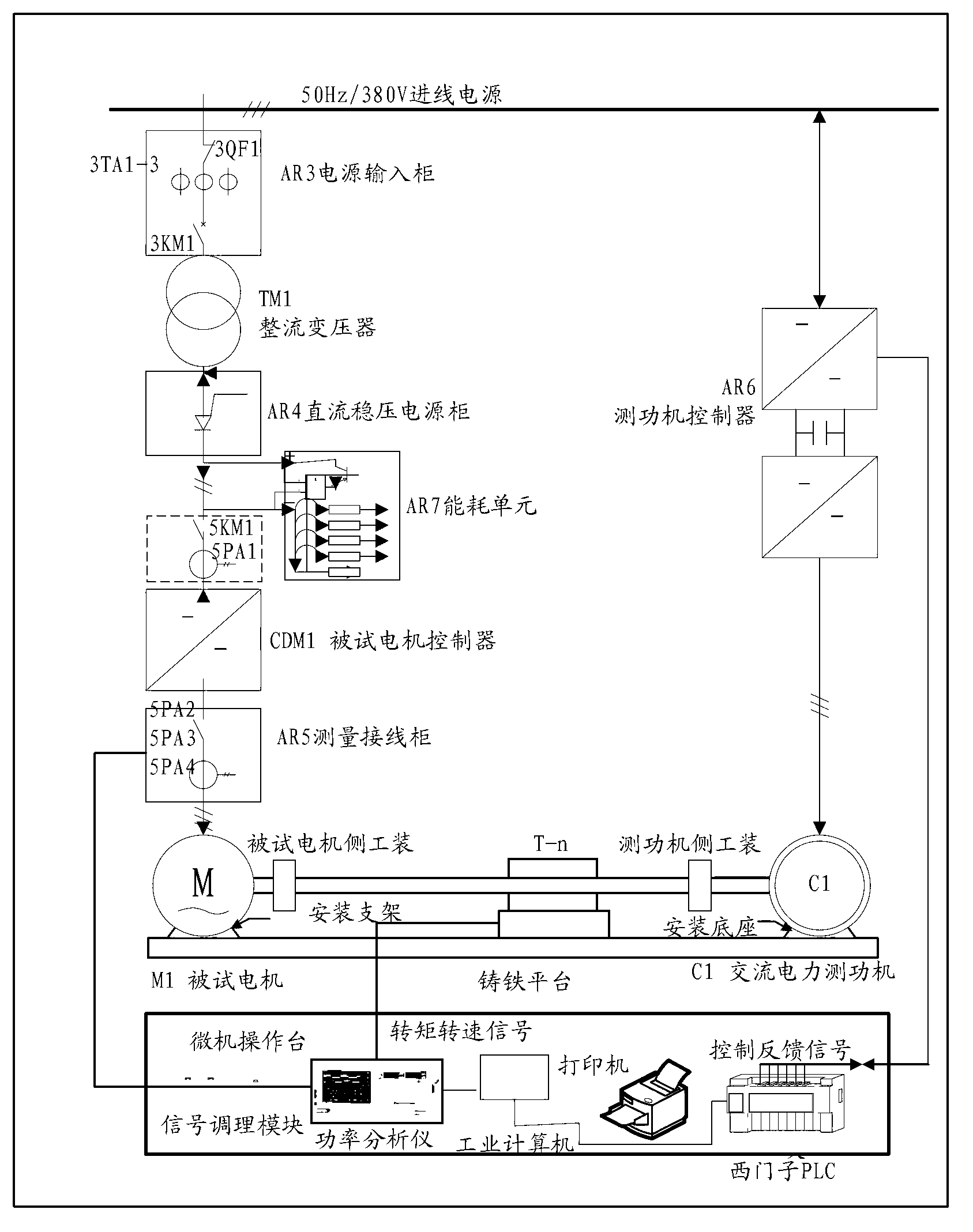

[0040] image 3 It is a structural block diagram of an electric vehicle motor test system according to Embodiment 2 of the present invention.

[0041] Such as image 3 As shown, the test system includes the following components:

[0042] The incoming power supply AR3 power input cabinet is equipped with a line protection circuit breaker and a breaking contactor. The incoming power supply cabinet is used for...

Embodiment 3

[0047] Figure 4 It is a flow chart of the electric vehicle motor test control method according to Embodiment 3 of the present invention.

[0048] Such as Figure 4 As shown, the method includes the following steps:

[0049] Step 401: Control the operation of the motor under test to simulate the state of the motor when the electric vehicle is running;

[0050] Step 402: Control the AC power dynamometer to provide resistance for the motor under test according to the running state of the motor under test;

[0051] Step 403: Detect the speed value, torque value, and response time value corresponding to each running state of the motor under test.

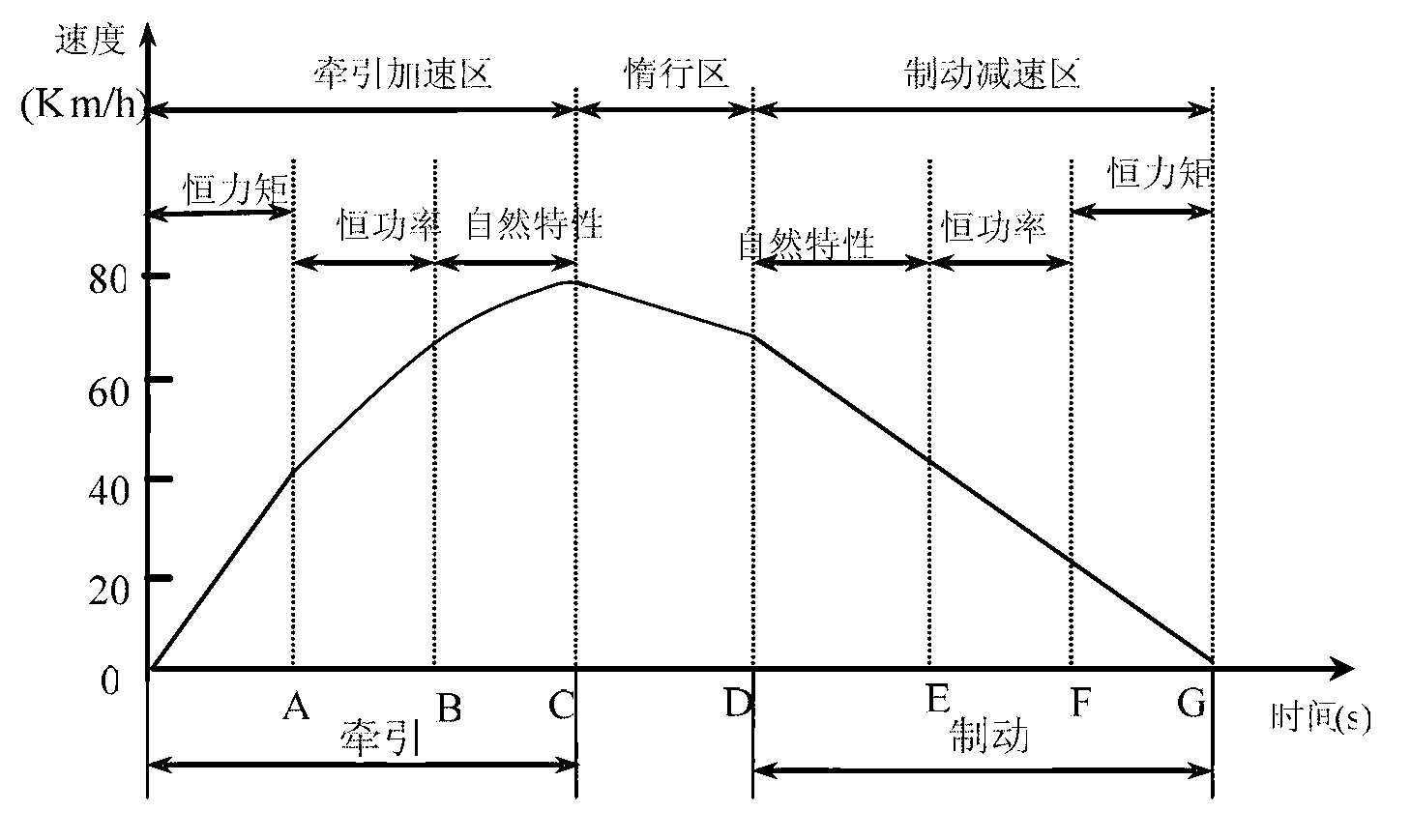

[0052] The electric vehicle motor test control method in this embodiment is mainly used to control the various equipment of the electric vehicle motor test system to realize the traction and electric braking conditions of the electric vehicle. The car is towed, and its output power is transmitted to the AC power dynamometer in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com