Electrical kiln used for firing cadmium red glaze porcelain with three-meter height

A technology for cadmium red and porcelain, applied in the field of firing three-meter high cadmium red glazed porcelain electric kilns, can solve the problems of differences in red gloss and vividness, large temperature difference between upper and lower, and low product quality, etc., and achieve glossiness. Consistent, reasonable arrangement, high product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

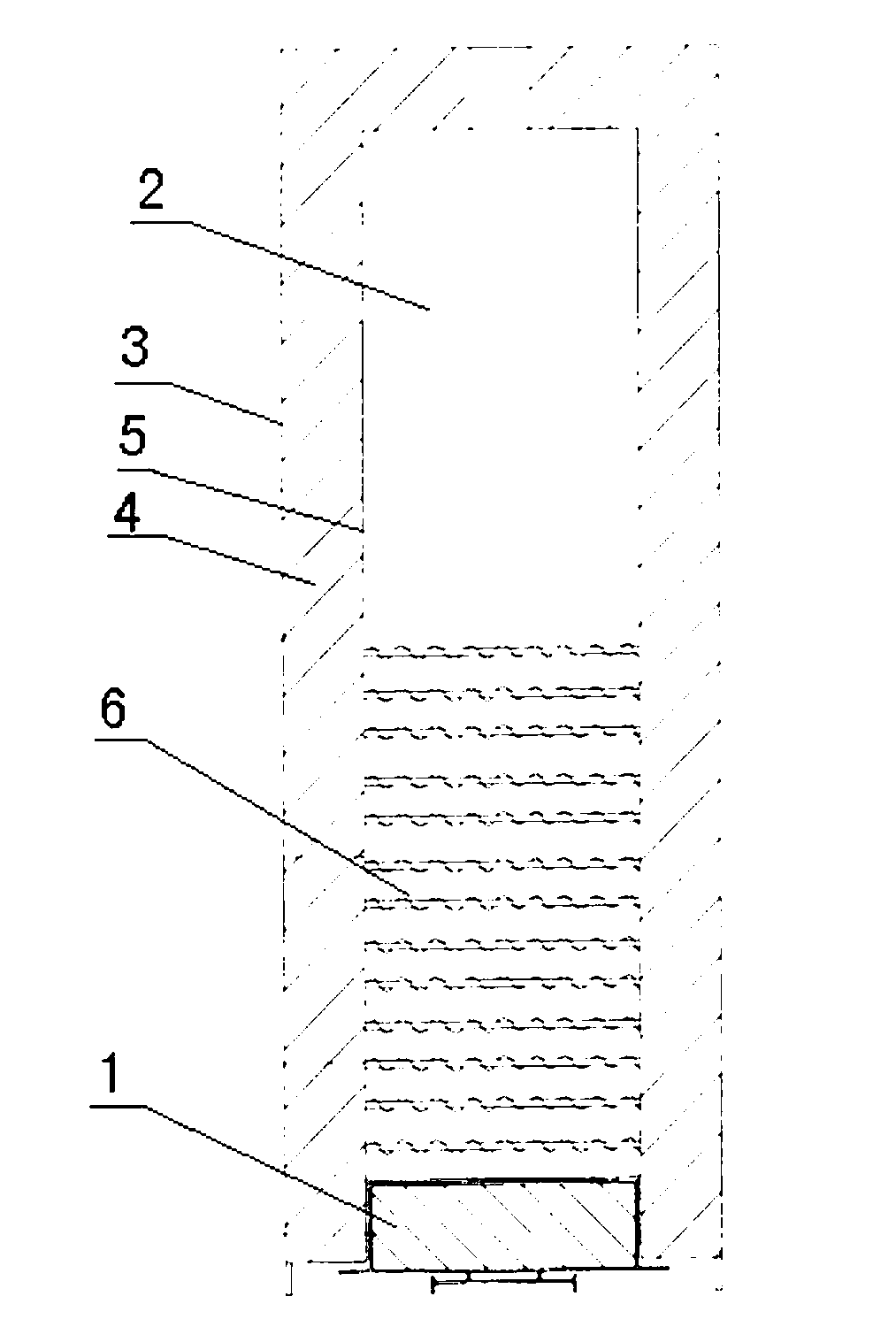

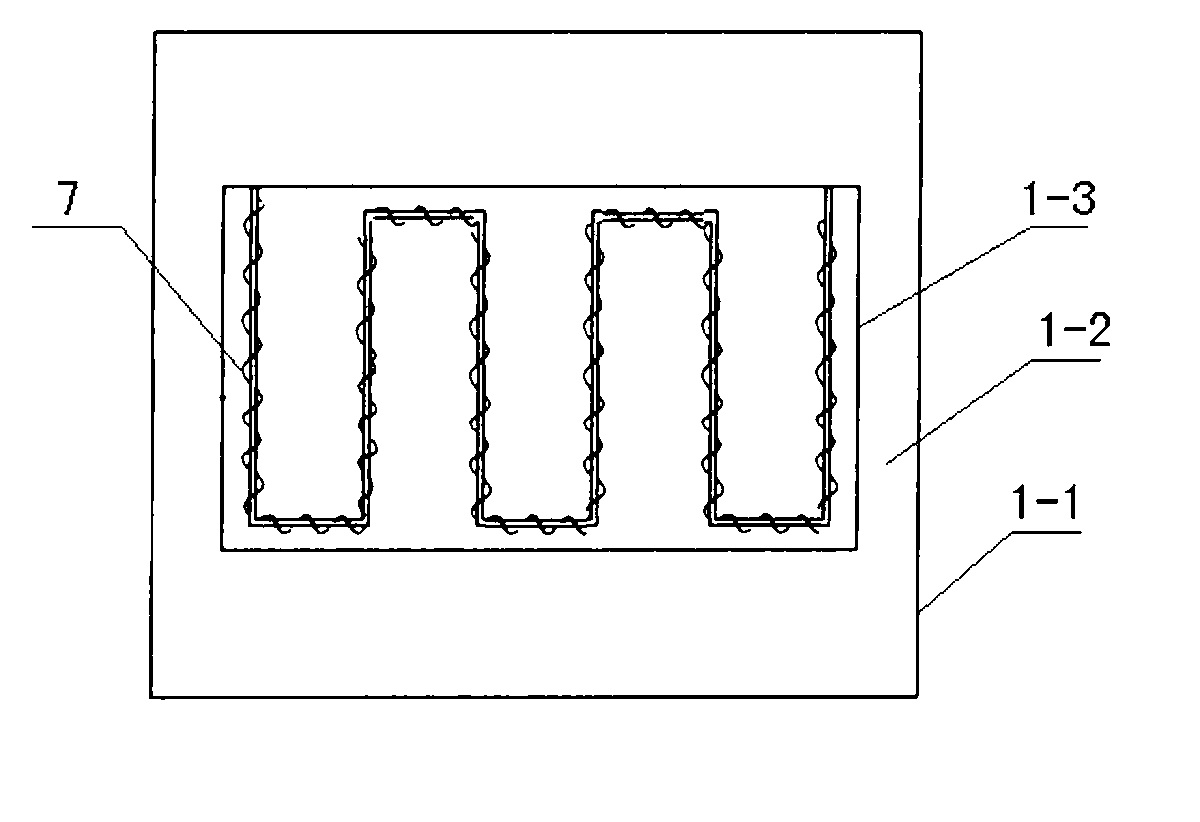

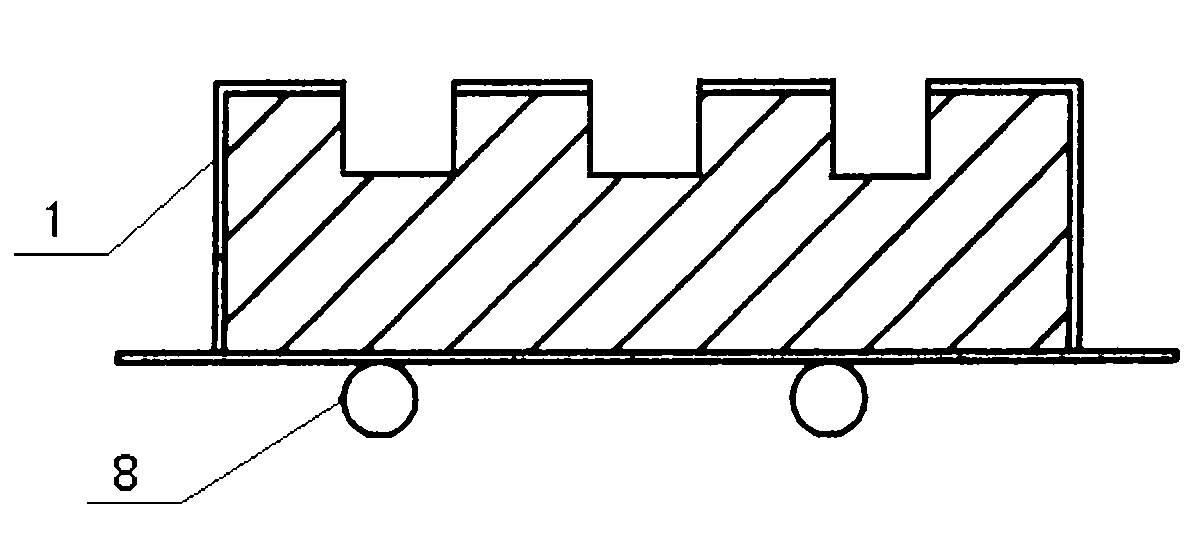

[0017] refer to figure 1 , 2 , the present embodiment comprises a furnace body and a base 1, the furnace body is provided with a furnace 2, the furnace body is provided with a furnace shell 3, between the furnace shell 3 and the furnace 2 is provided with a first insulation layer 4, the first insulation layer 4 The inner side is provided with a first heat-resistant layer 5, and the base 1 includes a base shell 1-1, a second heat-resistant layer 1-2 and a second heat-resistant layer 1-3, and the second heat-resistant layer 1-2 is arranged on the base Between the seat shell 1-1 and the second heat-resistant layer 1-3, the furnace 2 is provided with a first heating resistance wire 6, and the base 1 is provided with a second heating resistance wire 7, and the first heating resistance wire 6 is arranged on In the middle and lower part of the furnace 2, the space occupied b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com