Vertical low-carbon and energy-saving counter burning furnace

A back-burning furnace and vertical technology, which is applied in the field of vertical low-carbon and energy-saving back-burning furnaces, can solve the problems of limited use range, low thermal efficiency, no heat exchange function, etc. The effect of increasing the coefficient and increasing the number of air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

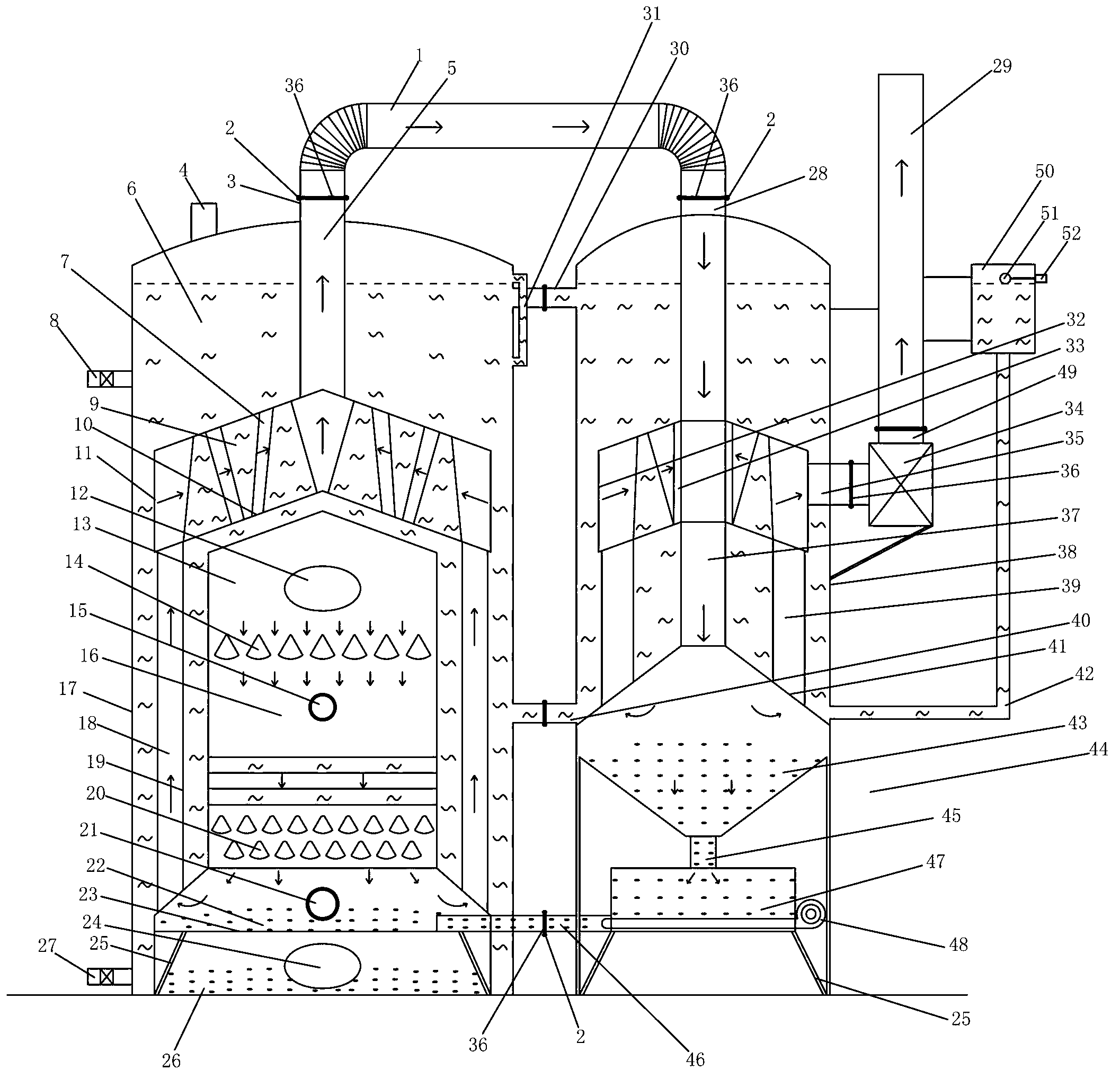

[0028] The present invention will be further described below in conjunction with the accompanying drawings in the specification:

[0029] As attached figure 1 , Attached figure 2 , Attached image 3 As shown, the present invention discloses a vertical low-carbon energy-saving counter-burning furnace, including a vertical cross-section arranged in the middle and lower part of the counter-burning furnace body 17 in a "convex" shape. There is a larger horizontal furnace liner 11, and the two furnace lines are connected by a plurality of straight fire tubes 18 surrounding the middle and upper part of the vertical anti-burning furnace liner 19, and a waste heat flue is provided on the top of the horizontal furnace liner 11. 5. The lower end of the waste heat flue 5 is connected to the horizontal furnace liner 11, and the top of the upper part passing through the back burner body is the waste heat flue outlet 3, and a soot back-burning waste heat exchanger 44 is provided on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com