Integrated down lamp

An all-in-one, downlight technology, applied in lighting devices, cooling/heating devices for lighting devices, electric light sources, etc., can solve the problems of not more than 1000 hours, shortened light source life, and intolerant of frequent switching, and prolong the service life. , Improve luminous efficiency and prevent visual fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

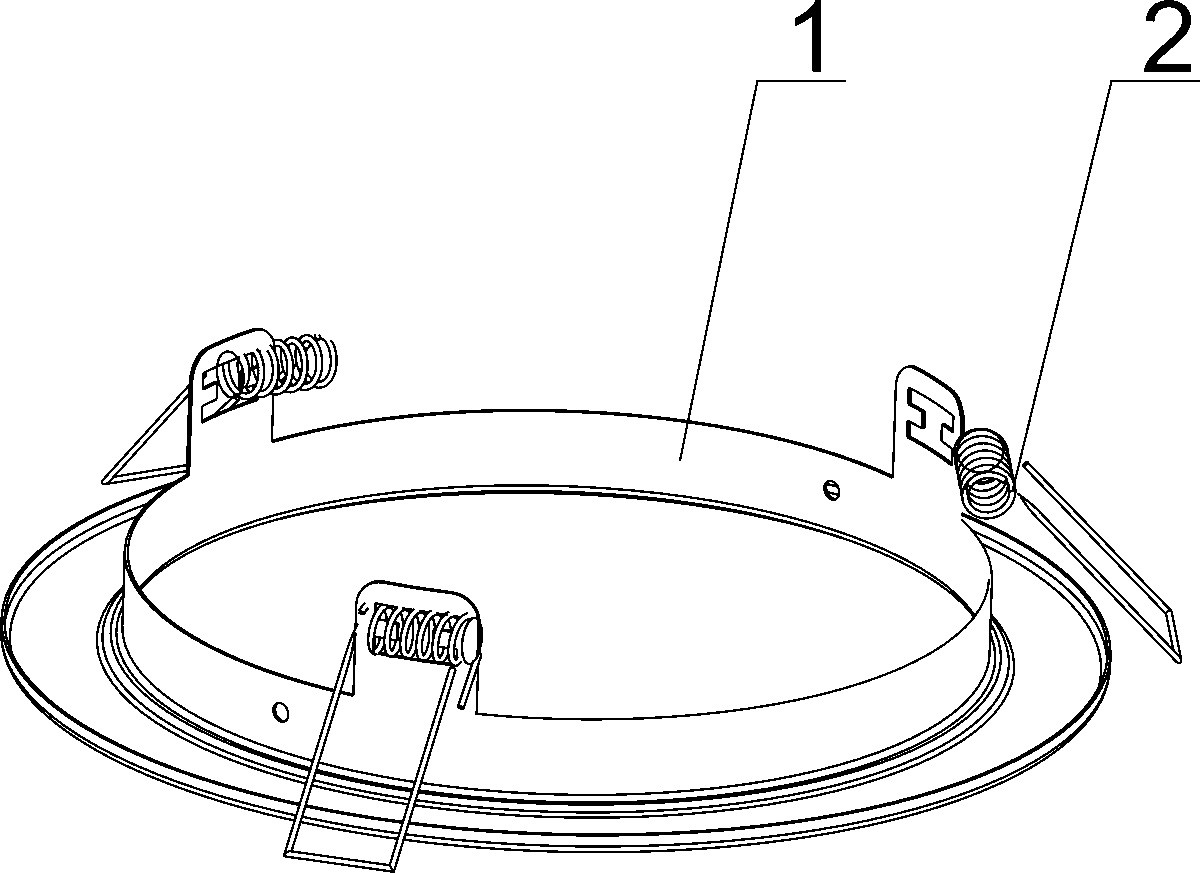

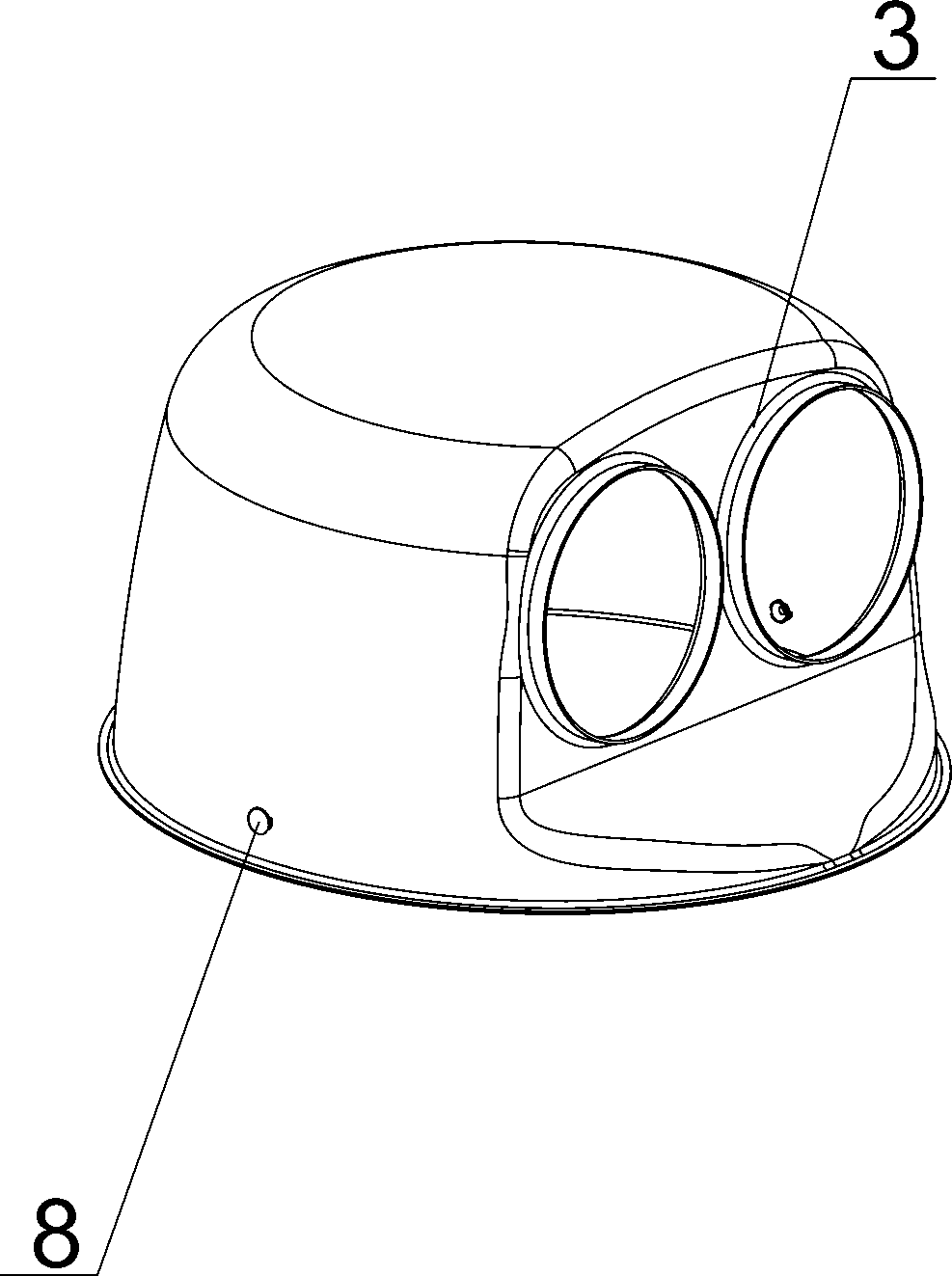

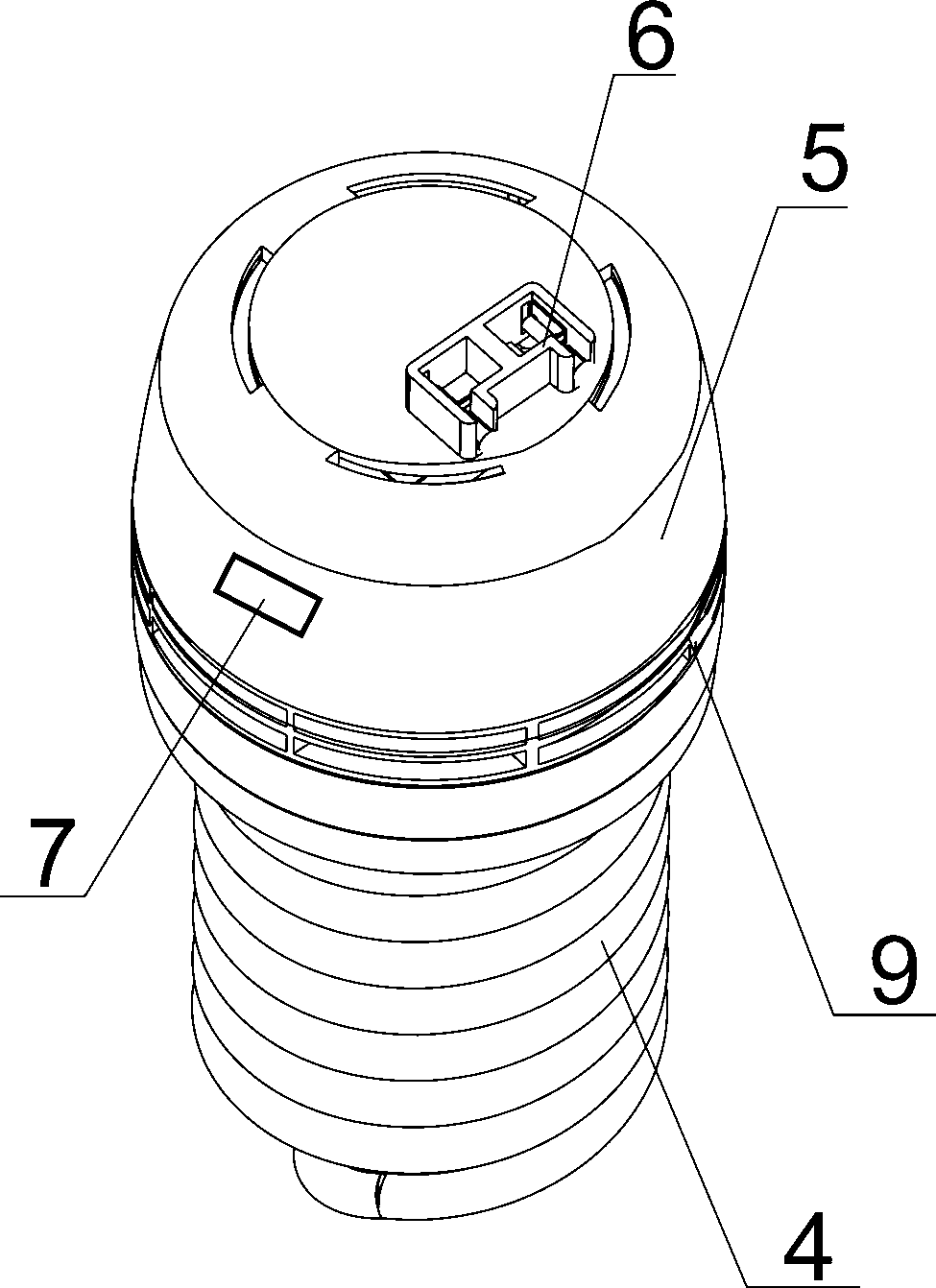

[0032] The integrated downlight of the present invention includes a face ring 1 provided on the bottom surface of the reflector cup 3, and a spring buckle 2 is provided on the side of the face ring 1, which is convenient for installation; the lamp tube fixing seat 5 is installed on the outside of the upper side of the reflector cup 3, The reflective surface of the reflective cup can be fully utilized; the cold cathode fluorescent lamp tube 4 is fixed on the lower bottom surface of the lamp tube holder 5 by glueing, the electrode of the cold cathode fluorescent lamp tube 4 is connected to the output end of the inverter 7, and the junction box 6 is connected to the output terminal of the inverter 7. The input terminal of the inverter 7 is connected. There are at least two spring clasps 2 . The self-locking fast plug-in terminal block 6 is provided with a self-locking wiring card, and the wiring is convenient and fast.

[0033] Such as image 3 As shown, the CCFL tube 4 is in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com