Multi-section molded line cam

A multi-stage, cam technology, applied to engine components, fuel injection pumps, machines/engines, etc., can solve problems such as high fuel injection pressure and fuel injection rate, difficulty in increasing and small fuel injection volume control, and long duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in more detail below in conjunction with accompanying drawing example:

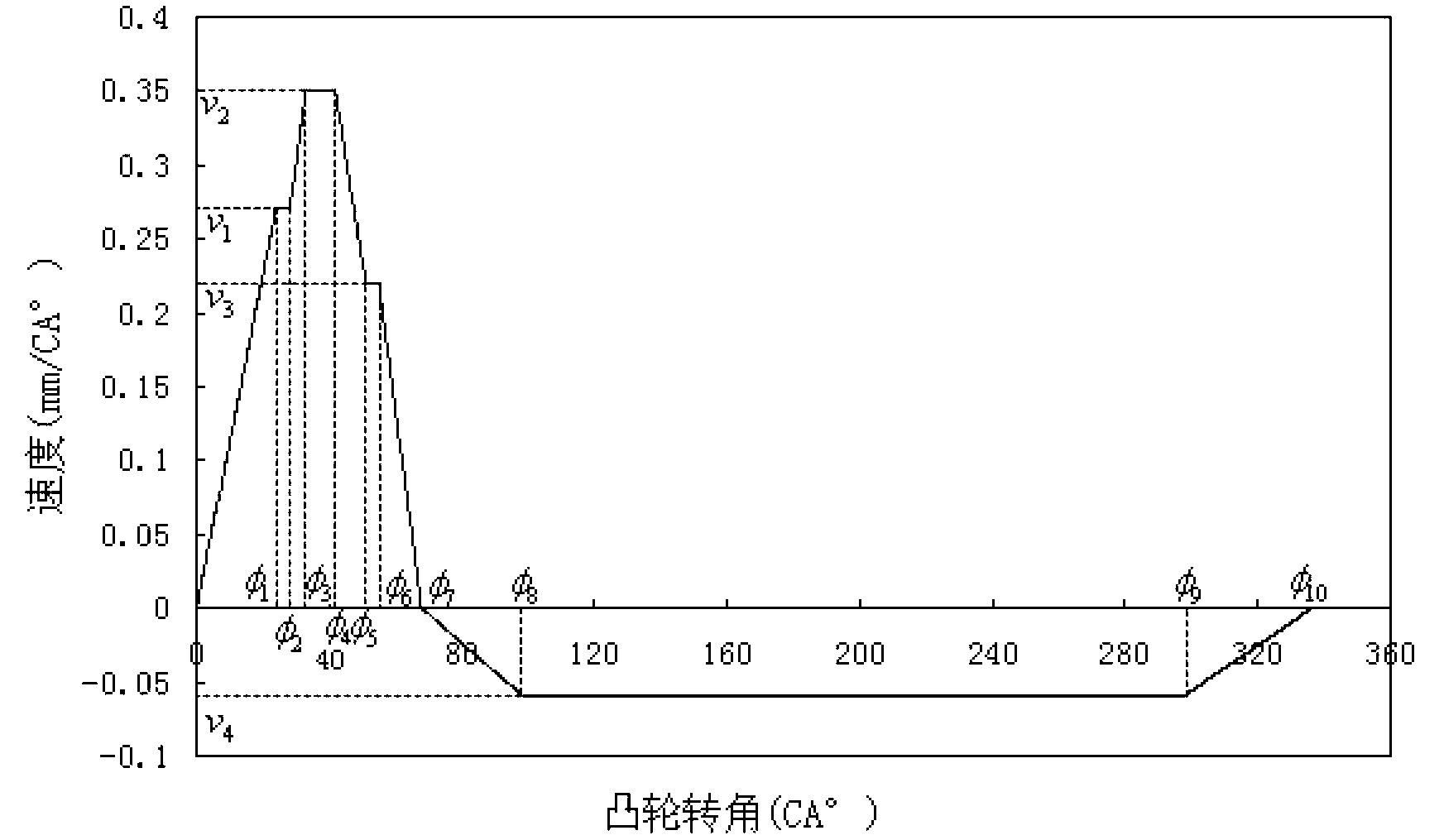

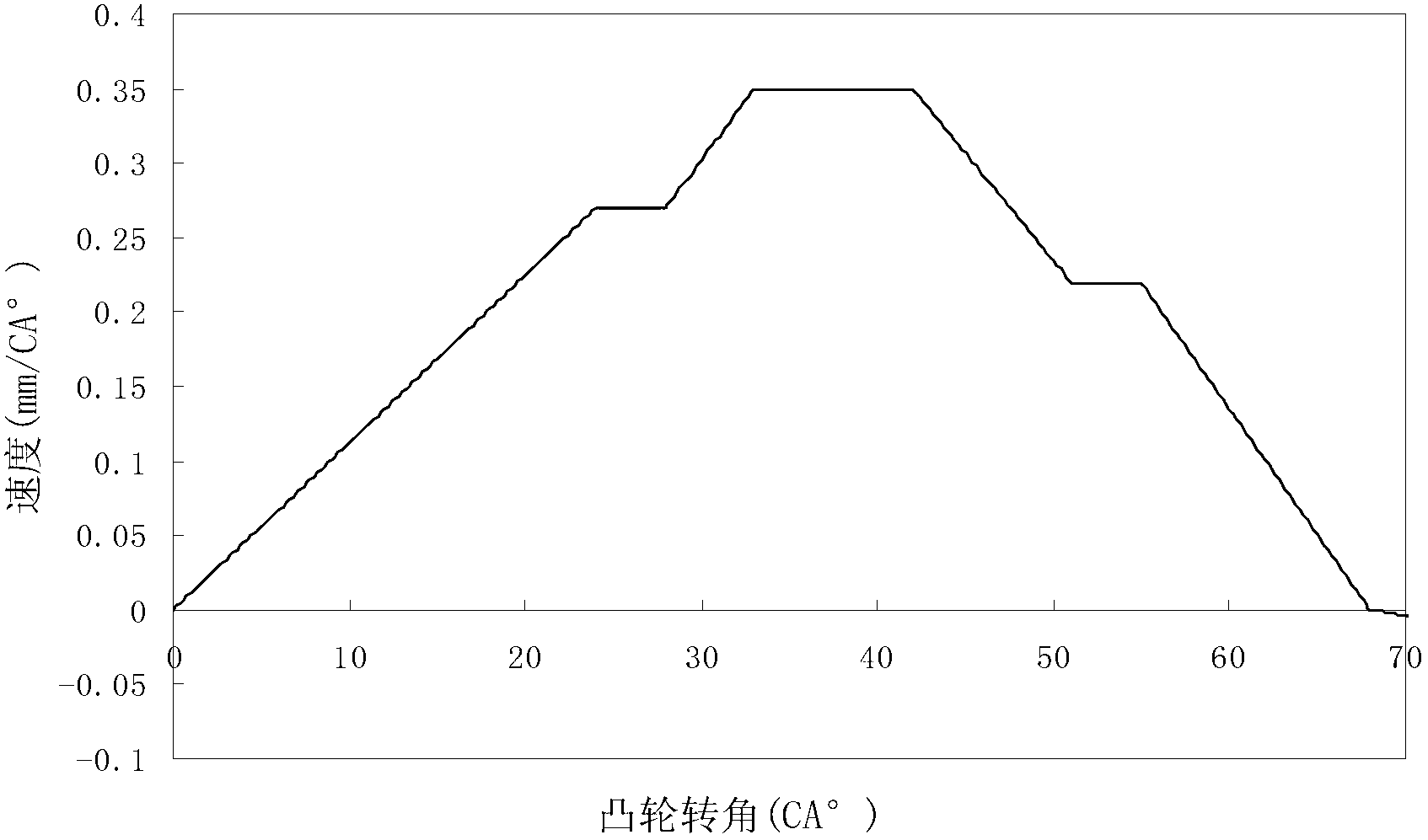

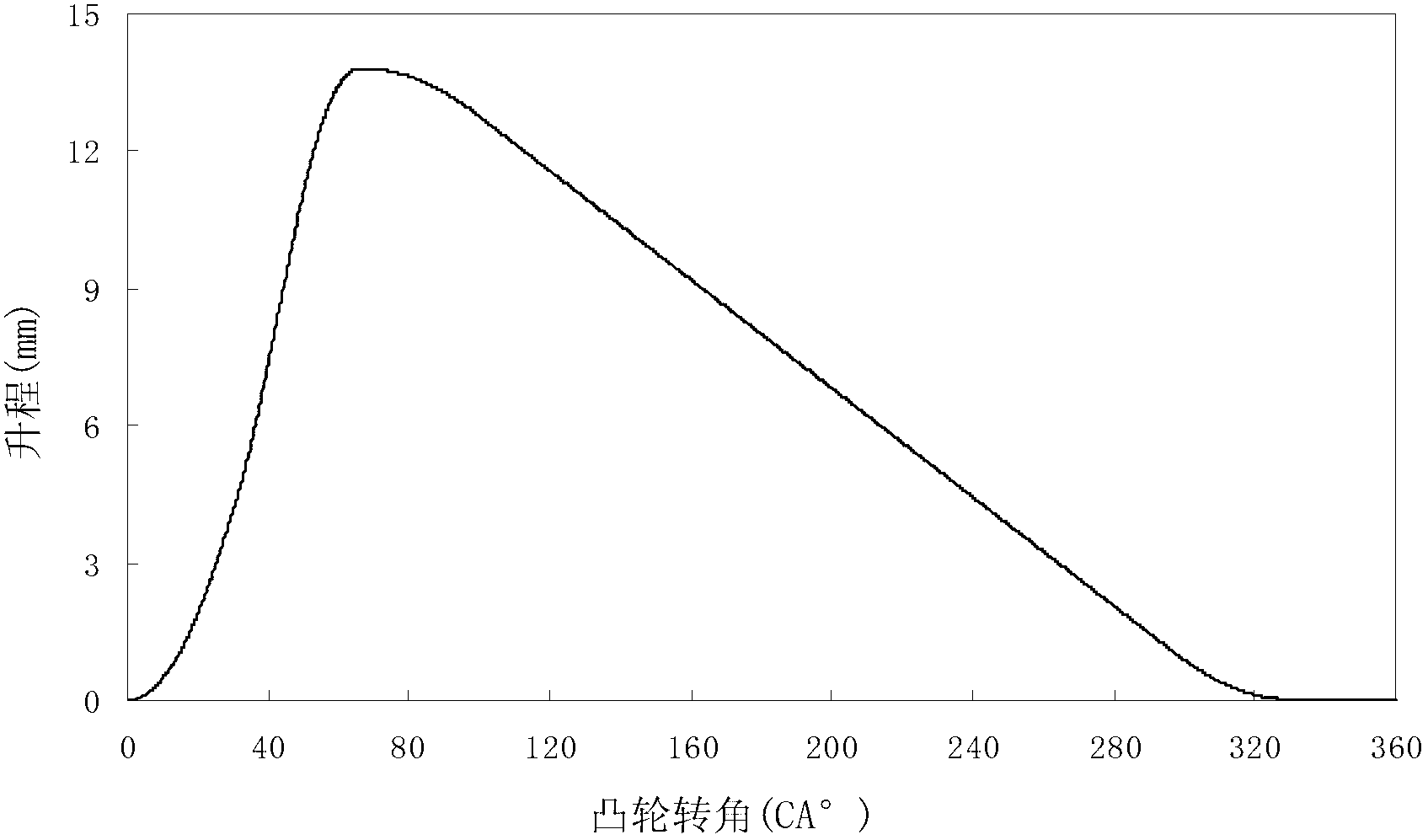

[0048] 1-3, the multi-stage cam profile of the present invention, its thrust section corresponds to two positive constant acceleration stages, three positive constant velocity stages and two forward constant deceleration stages of the movement law of the plunger follower stage, in which the second constant velocity stage has a higher speed and a longer duration than the other two constant velocity stages; the return section of the cam corresponds to the reverse constant acceleration stage and reverse constant velocity deceleration phases such as phase and reverse. Its working section is the three constant speed stages of the thrust section, the second constant acceleration stage and the first constant deceleration stage. The speed curve and lift curve are shown in Figure 1 and Figure 2 respectively. The equations of motion for each segment of the plunger follower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com