Structure and method for preventing large deformation slippage of lateral wall of high stress tunnel

A sliding structure, high-stress technology, applied in the direction of earth drilling, mining equipment, installation of bolts, etc., can solve the problem of promoting the use of difficult and high-stress roadways, destroying the overall structure of high-stress roadways, and difficult to form high-strength support structures and other issues, to achieve the effect of good promotion value, wide practicability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with an embodiment in the accompanying drawings:

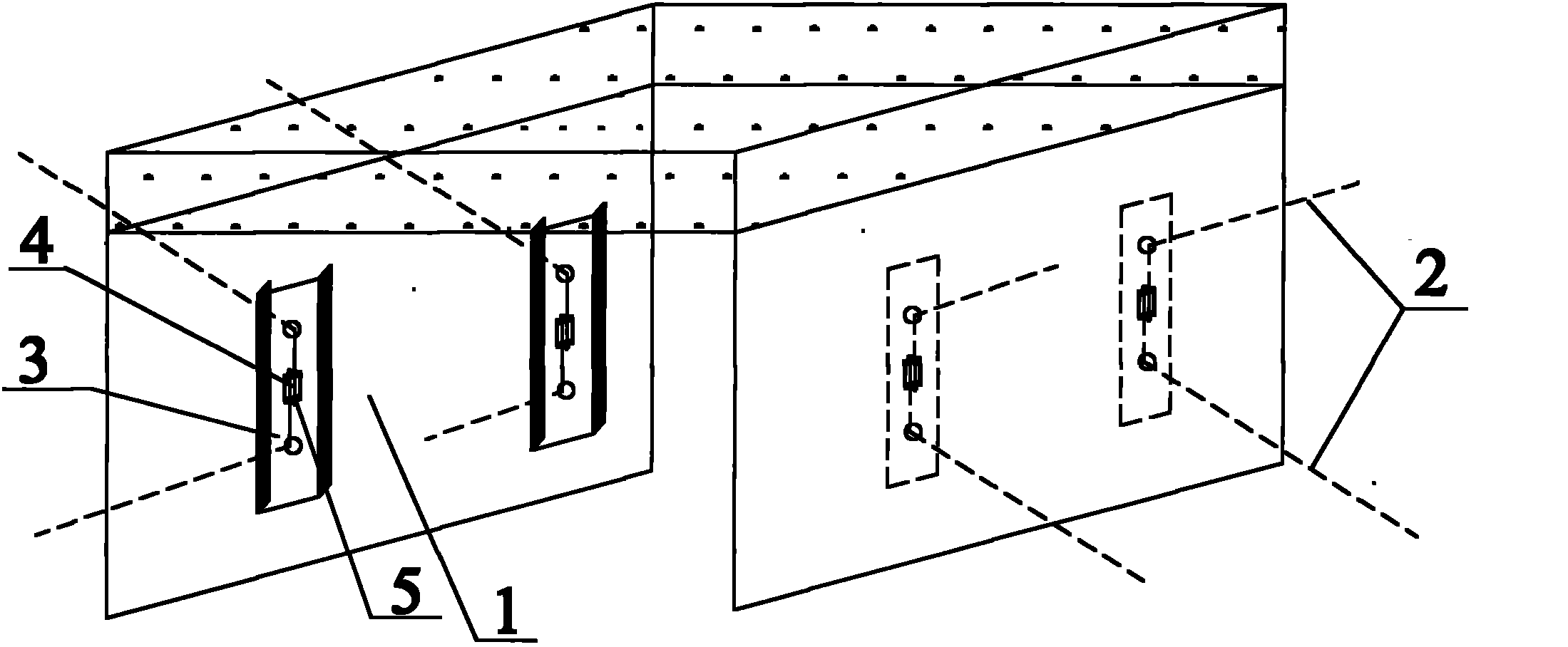

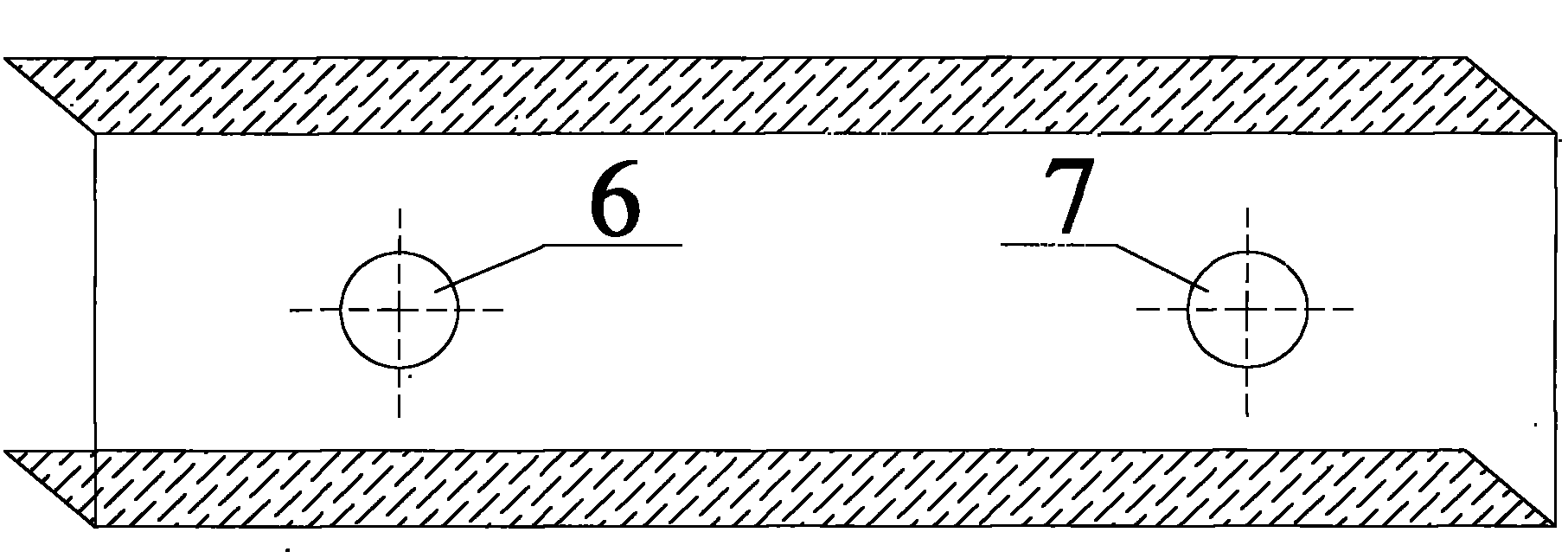

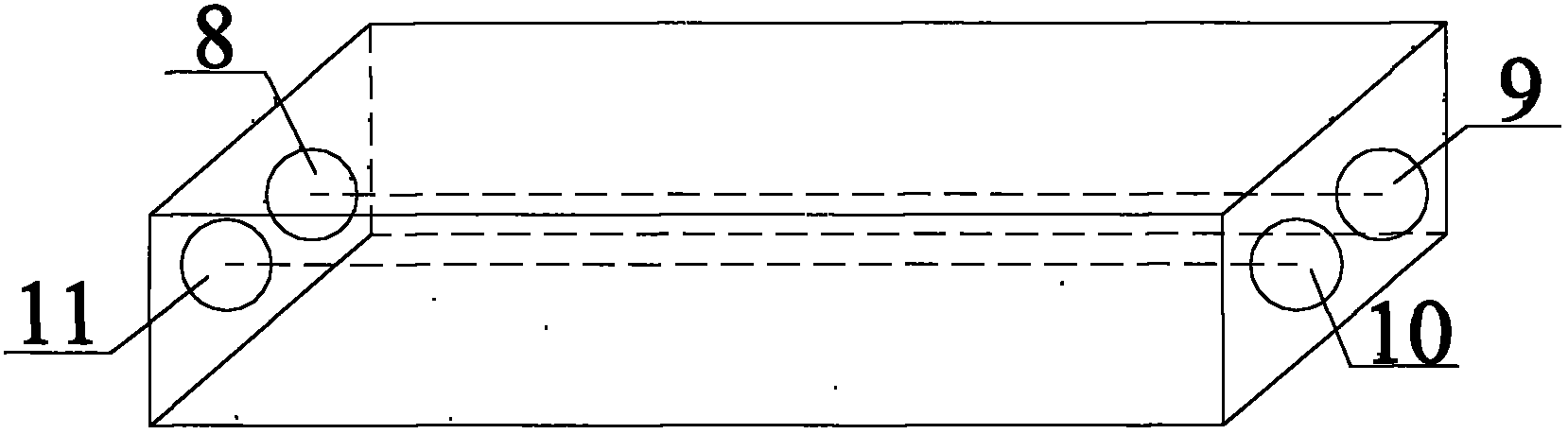

[0014] The invention discloses a method for preventing the large deformation and slippage of the side walls of high-stress roadways. The high-stress roadway side 1 is adopted. The high-stress roadway side is composed of high-stress coal and rock media on both sides between the top and bottom of the roadway, and has high strength, low relaxation and large diameter. Anchor cable 2, channel steel 3, cuboid coupler 4 and lockset 5. The specific implementation steps are: after the roadway is excavated, use the anchor cable drilling rig to drill two round holes to the upper and lower regions of the high-stress roadside, and install the channel steel 3 on the high-stress roadside 1 along the vertical direction of the roadway axis. The specific steps are: Drill two holes on the side of the high-stress roadway, and then install anchor cables in the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com