Gas non-contact type high efficiency energy recovery device

A non-contact, energy recovery technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of restricting the promotion of heat pipe technology, low efficiency, and low heat exchange efficiency, and achieve continuous adjustment of working conditions and avoid Cross-contamination, easy processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

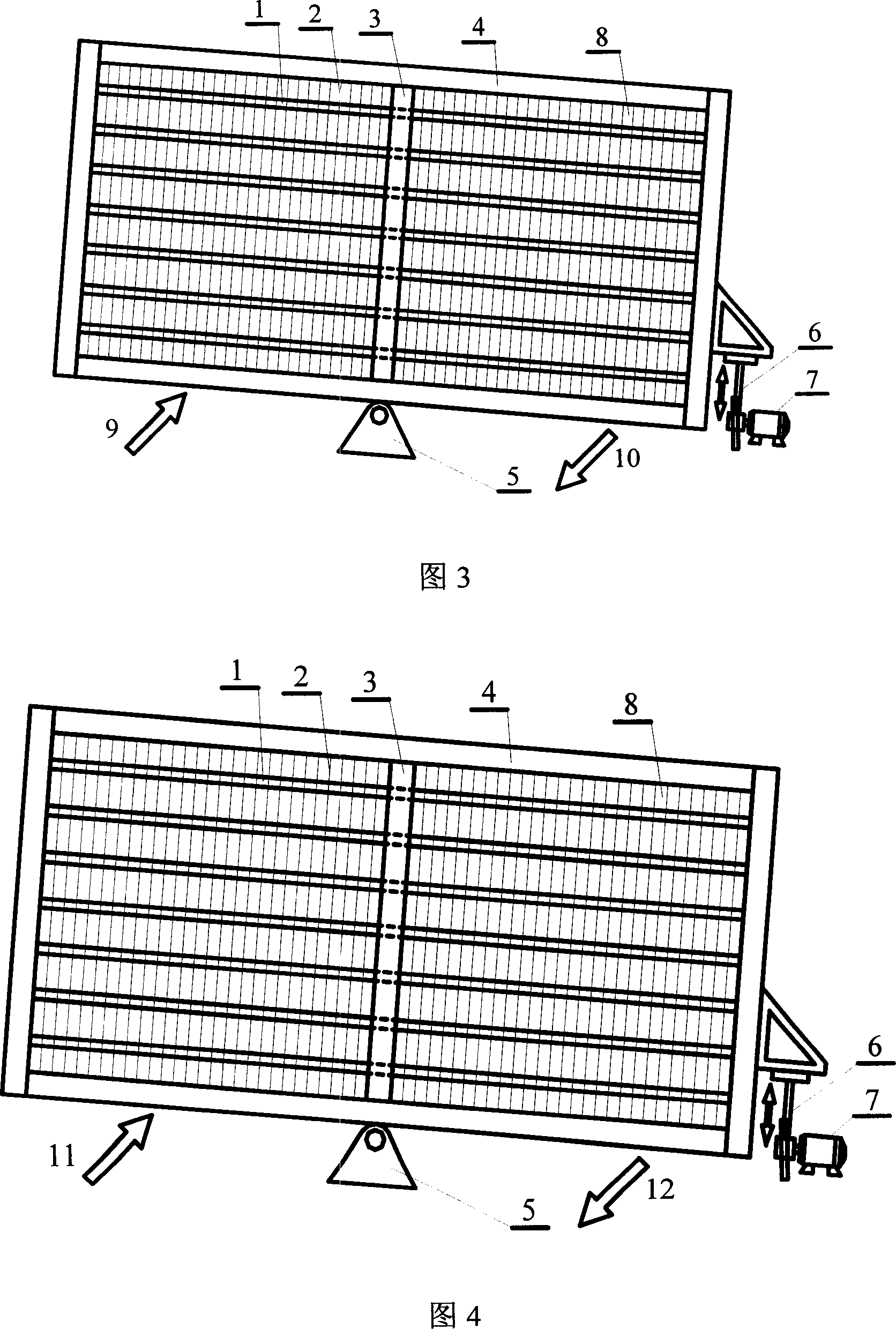

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0015] Referring to Fig. 1, a non-contact building ventilation heat efficient energy recovery device with mutually isolated working fluids includes a thermosiphon 1, fins 2, partitions 3, an outer frame 4, a support 5, a push rod 6 and a driving device 7. Thermosiphon 1 is made of copper tube, aluminum tube or Bondy tube closed at both ends. There is a certain amount of low-boiling-point working substance sealed in the thermosiphon 1, which can be a mixture of one or more low-boiling substances, such as methane, ethane halogenated or ethers, and chlorodifluoromethane in hydrocarbon organic substances, Dichlorotrifluoroethane, propane, propylene, hydrofluoroether or mixtures of pentafluoroethane / trifluoroethane / tetrafluoroethane, mixtures of pentafluoroethane / difluoromethane, etc. A plurality of thermosiphon tubes 1 are coated with a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com