Technology for processing soil filled slope by combining geogrids and concrete panels

A geogrid, concrete panel technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of monotonous slope, uneven slope, soil loss, etc., and achieve the effect of speeding up construction and preventing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

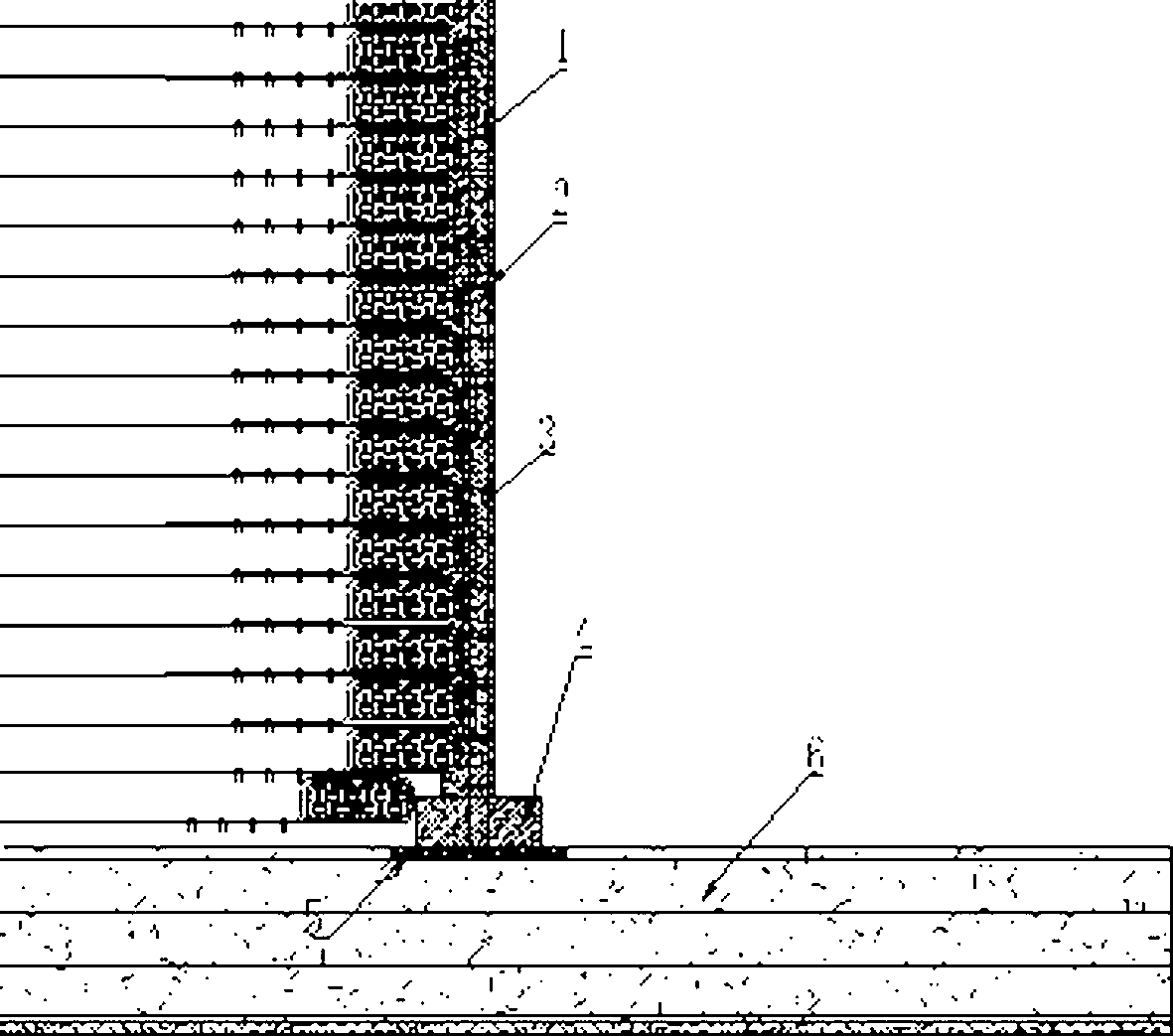

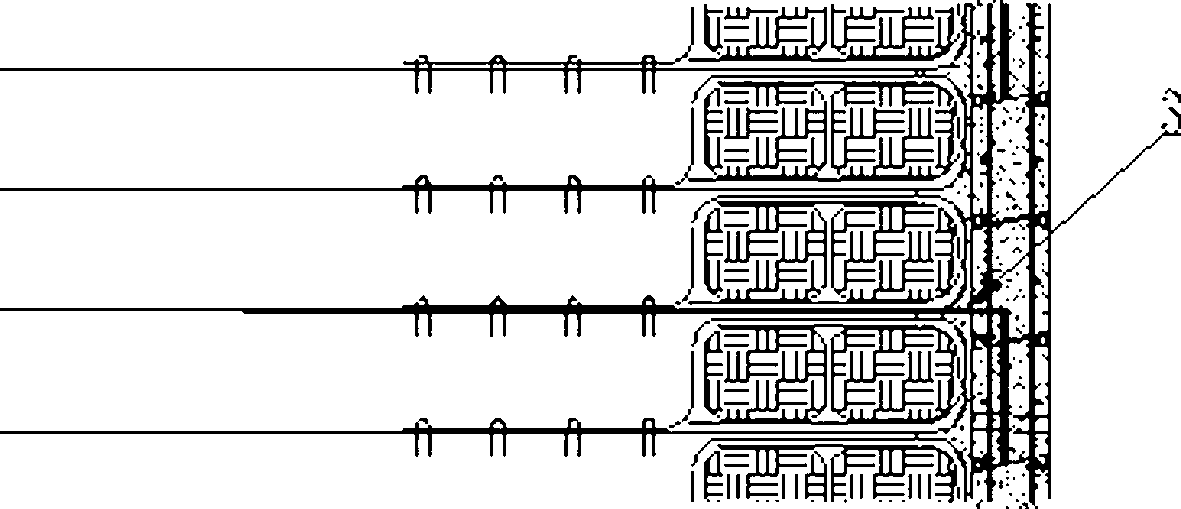

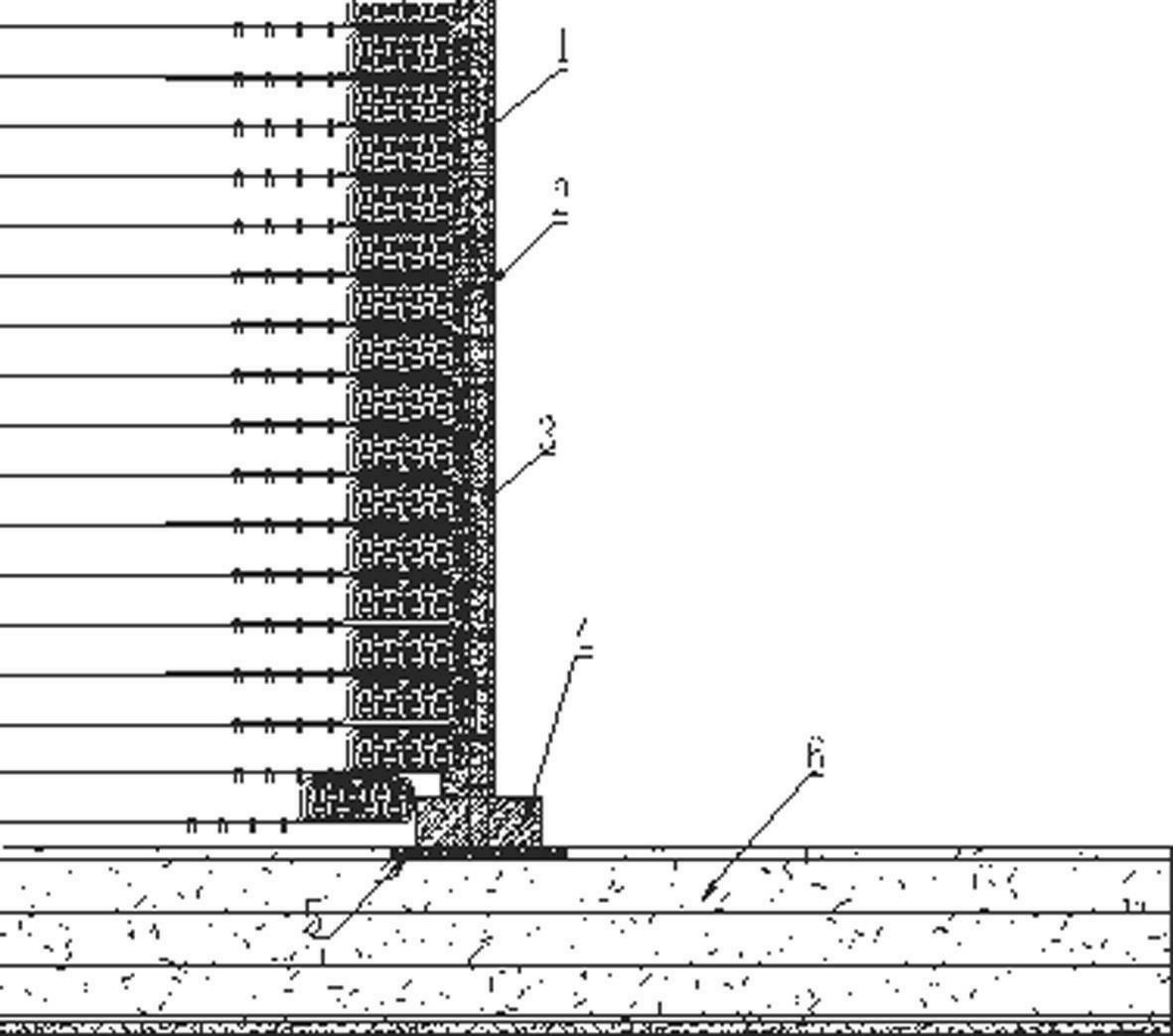

[0016] Root attached figure 1 . figure 2 As shown in (1) first, if the bearing capacity of the shallow part of the foundation does not meet the requirements, replace it first, then level it up to the design elevation, lay a layer of geogrid + graded gravel cushion on the ground ⑥, and pour C15 concrete Cushion layer ⑤, and then start to make concrete ground beams ④. The height of the ground beams is required to be slightly higher than that of the first layer of grids. The geogrid is compressed and fixed with bagged gravel, and the pre-embedded steel bar ③ is placed on the top, and the front end of the steel bar is made into a hook; (2) After the geogrid is laid to a certain height, the concrete panel ① is started on the ground beam, The pre-placed steel bars are connected with the panel steel bars (main bars, tie bars ②), and at the same time, they are used as concrete formwork fixing measures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com