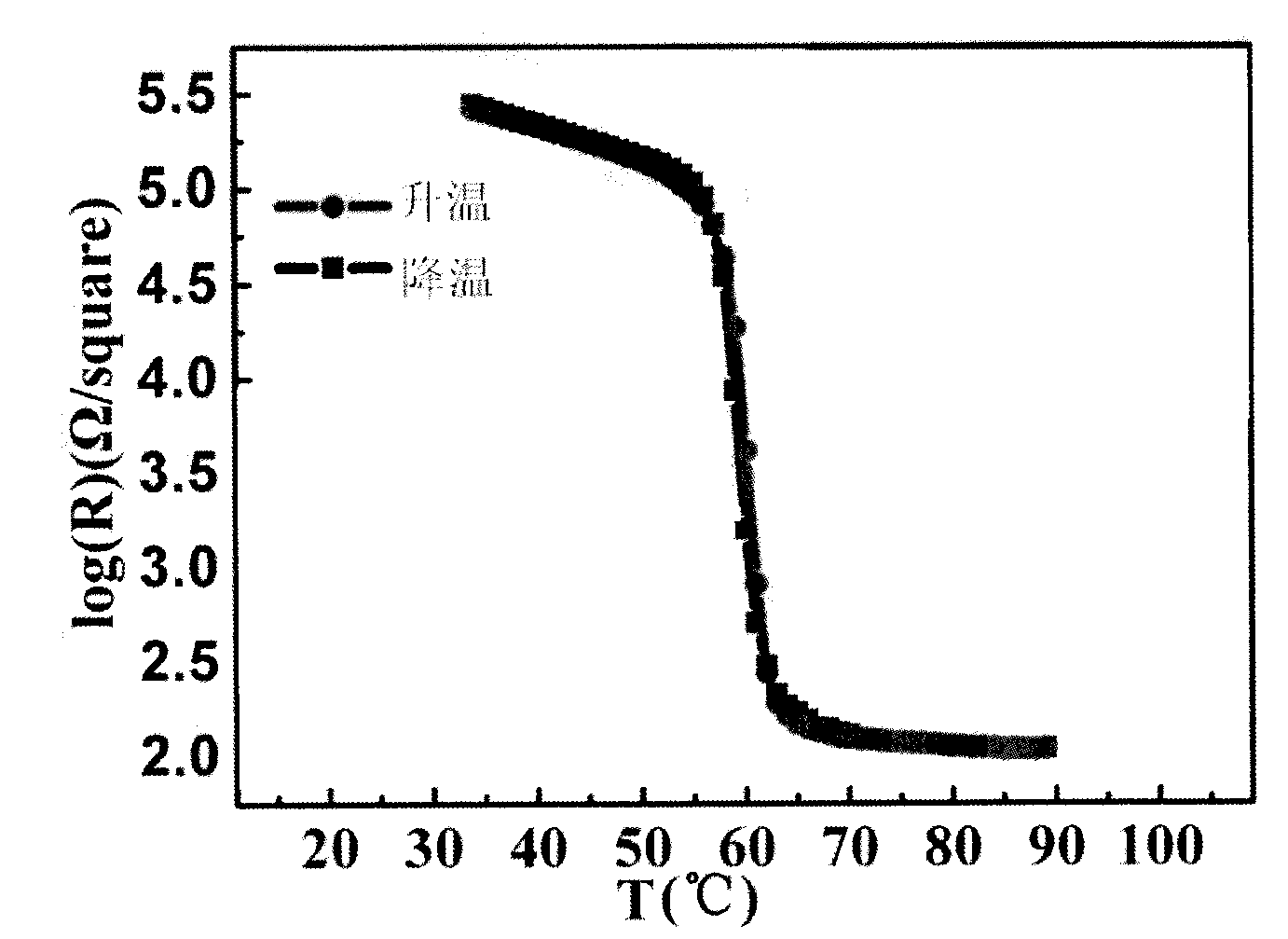

Preparation method of vanadium dioxide thin film of extremely narrow hysteretic curve width and high temperature coefficient of resistance

A temperature coefficient, thin film preparation technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of reducing material TCR, limiting application, temperature hysteresis, etc., achieving good repeatability and simple preparation method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

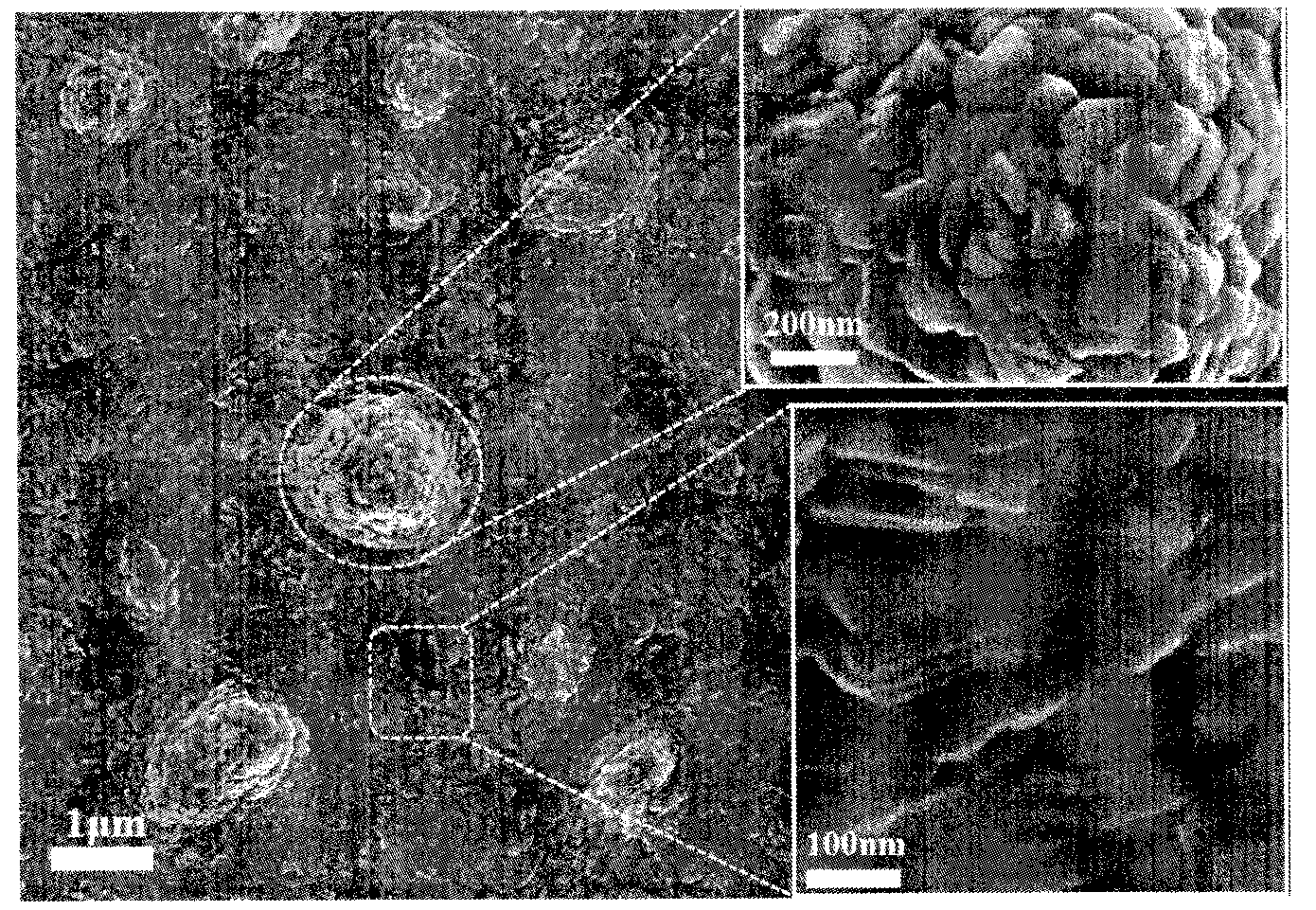

[0022] First, using the metal vanadium target of the JPGF400B-G magnetron sputtering apparatus to Al 2 o 3 The substrate is subjected to DC sputtering to prepare metal vanadium thin films. Al adopted 2 o 3 The substrate is 0001 oriented and the thickness is 0.5mm; the purity of the metal vanadium target used is 99.7%, the diameter of the target is 60mm, the distance between the target and the substrate is 180mm, and the rotation speed of the substrate is 13.6r / min to maintain the uniformity of the film sex. Pre-sputter for 15 minutes to clean the target surface before coating. The preparation parameters of metal vanadium thin films are shown in Table 1.

[0023] Table 1 Preparation parameters of metal vanadium thin film

[0024]

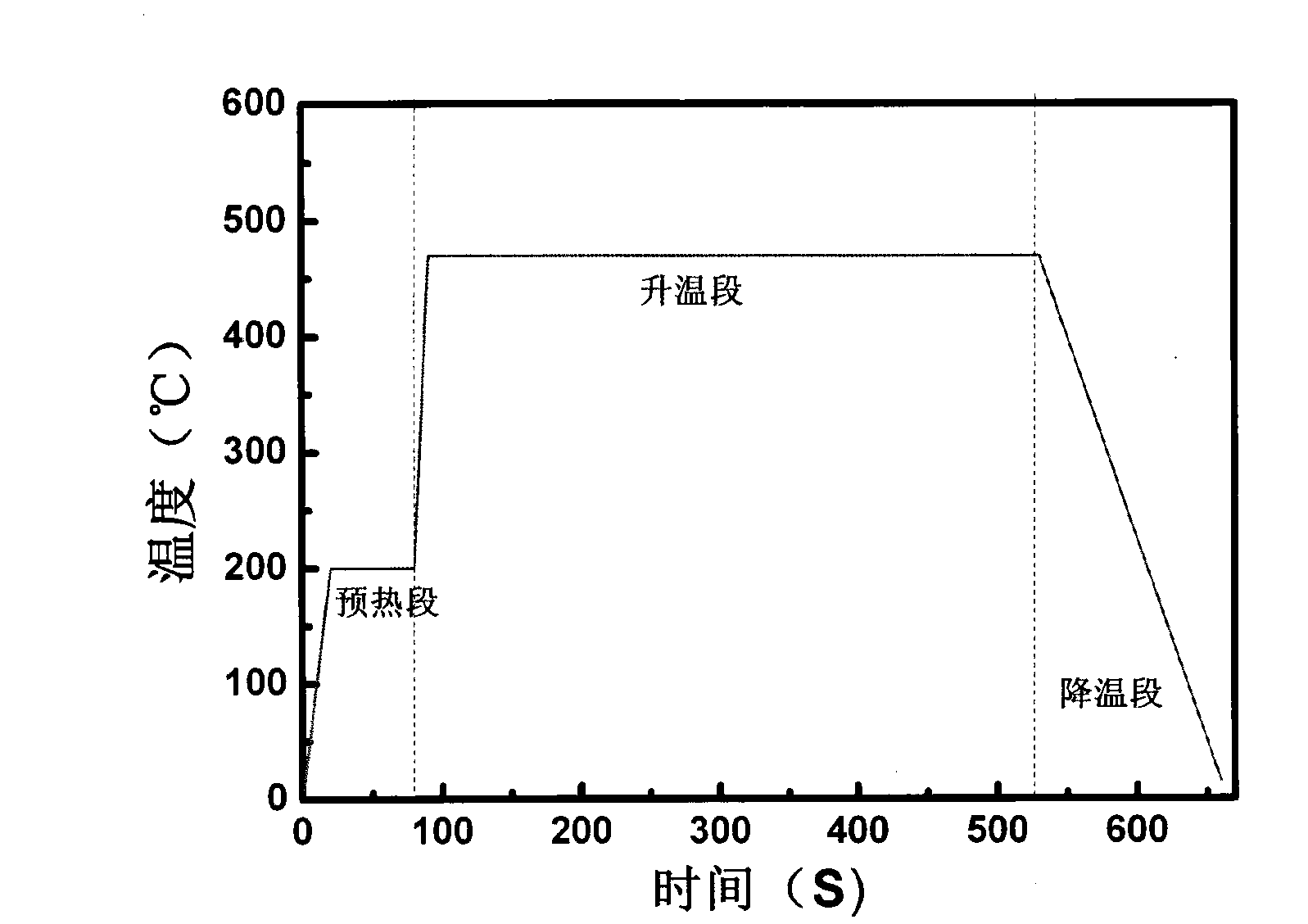

[0025] Place the prepared metal vanadium film in the RTP-500 rapid heat treatment equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com