Material for overweight ring forging and manufacturing process for ring forging

A manufacturing process and ring forging technology, applied in the field of super-heavy ring forgings, can solve the problems of low plasticity and hardenability, unstable quality, etc., and achieve the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The material for super-heavy ring forgings of the present invention and the manufacturing process of the ring forgings will be further described in detail below through specific examples.

[0013] The weight percent composition of each chemical element contained in the super-heavy ring forging material is as follows: C: 0.41-0.45%, Si: 0.17-0.37%, Mn: 0.80-1.00%, P: ≤0.020%, S : ≤0.020%, Cr: 1.05~1.20%, Ni: ≤0.30%, Mo: 0.20~0.25%, Cu: ≤0.20%, Al: 0.02~0.04%, the balance is Fe, and the content of oxygen and hydrogen elements Meet the following requirements: [O]: ≤20ppm, [H]: ≤2.0ppm. The above-mentioned 28t super heavy ring forging can be smelted by the process of "electric furnace + refining outside the furnace + vacuum degassing" and manufactured by die casting to obtain steel ingots.

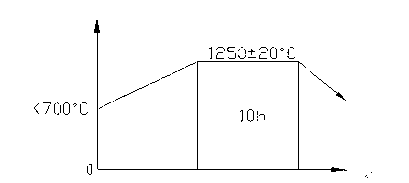

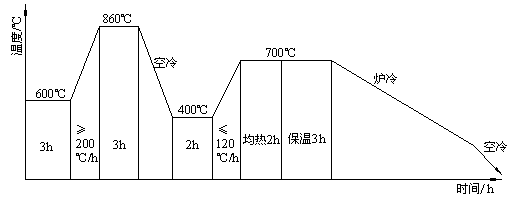

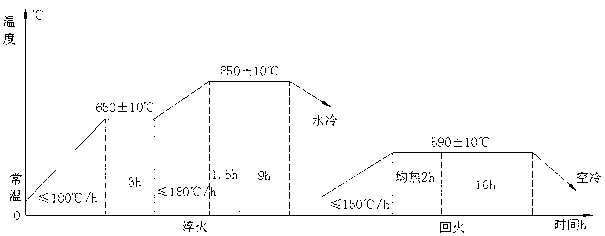

[0014] The technological steps of manufacturing super-heavy ring forgings from the above materials include blanking, forging billets, ring rolling, heat treatment and machining.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com