Cyanate ester based thermosetting resin and application thereof

A resin composition and thermosetting technology, applied in the application field of the composition, can solve problems such as limiting the application of materials, and achieve the effect of excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

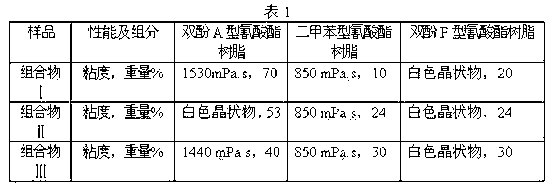

[0014] Examples 1-3 respectively prepared cyanate-based thermosetting resin compositions I-III, and the viscosities and weight percentages of components A, B, and C are shown in Table 1 below.

[0015]

[0016] Note: The above viscosity is measured at 70°C.

Embodiment 4~6

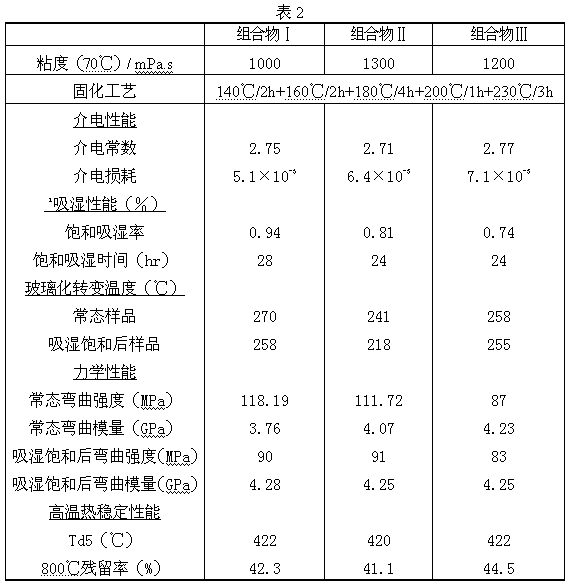

[0018] Examples 4-6 are the viscosity parameters of the compositions at 70° C., and the curing process and various properties of the cured materials are shown in Table 2. According to this curing process, the curing degree of the obtained materials is above 94%, and has excellent comprehensive properties under the premise of excellent dielectric properties.

[0019]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com