High-performance regenerated rubber and preparation method thereof

A reclaimed rubber, high-performance technology, applied in the field of high-performance reclaimed rubber and its preparation, can solve the problems of high energy consumption in the regeneration process and poor quality of reclaimed rubber, and achieve the effect of good regeneration effect, improved quality and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

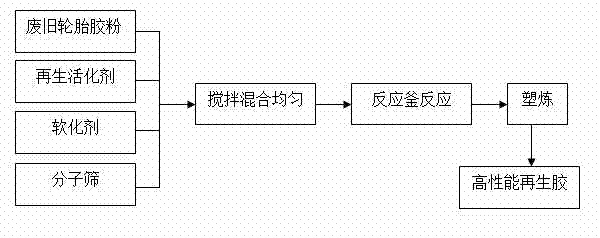

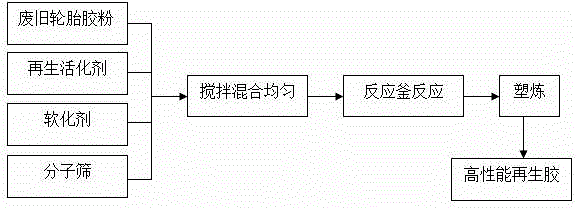

[0024] (1) Improve the preparation formula of waste rubber regeneration. Usually the composition of recycled rubber mainly consists of rubber powder, regeneration activator, softener, activator, tackifier, plasticizer and so on. The main components of the reclaimed rubber prepared by the present invention include waste tire rubber powder, ethyleneamines (diethylenetriamine, triethylenetetramine, tetraethylenepentamine) regeneration activators, petroleum resin softeners, and molecular sieve adsorbents. Their ratio (weight ratio) is 100:2-8:4-12:4-10 in turn.

[0025] (2) Improve the preparation method and process of regenerated rubber: based on the effect of chemical agents, combined with the effect of mechanical field to achieve the purpose of rubber powder regeneration. Mix the rubber powder, regeneration activator, softener and molecular sieve evenly, add it into the reactor, use the three-dimensional network of rubber that reacts in the reactor first, and make the chemical...

Embodiment 1

[0031] Take 100 parts of 40-mesh waste rubber powder, 4 parts of regeneration activator diethylenetriamine, 8 parts of aromatic (C9) petroleum resin softener, 4 parts of 3A molecular sieve adsorbent, stir and mix evenly and add to the reactor. The temperature is 180°C, and the reaction time is 3 hours. The regeneration activator and softener effectively penetrate the three-dimensional network structure of the rubber to make the rubber swell. Use cooling water to cool, reduce the temperature of the material in the reactor to 80°C, take it out and add it to the internal mixer for desulfurization. The temperature parameter of the internal mixer is 180°C, the internal mixing time is 10 minutes, and the speed of the internal mixer is 100 rpm. The desulfurization process first penetrates the regenerated activator and softener into the three-dimensional network of the rubber to make the rubber swell, which is beneficial to the fracture of the cross-linking point, and then uses the she...

Embodiment 2

[0033] In parts by weight, take 100 parts of 100-mesh waste rubber powder, 4 parts of regeneration activator triethylenetetramine, 6 parts of aliphatic (C5) petroleum resin softener, 8 parts of 4A molecular sieve adsorbent, stir and mix evenly Add the reaction kettle, the temperature of the reaction kettle is 180°C, and the reaction time is 1.5 hours. The regeneration activator and softener can effectively penetrate the three-dimensional network structure of the rubber to make the rubber swell. The swollen product from the reactor was taken out and added to the banbury mixer for desulfurization. The temperature parameter of the banbury mixer was 180° C., the banbury time was 8 minutes, and the speed of the banbury mixer was 80 rpm. The desulfurization process uses the regenerated activator softener to penetrate into the three-dimensional network of the rubber to make the rubber swell, which is beneficial to the fracture of the cross-linking point, and then uses the shear force ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com