Advanced municipal sewage treatment method

A technology for urban sewage and advanced treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, infiltration/dialysis water/sewage treatment, etc. Complex, increase the operating cost of the sewage treatment plant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1: Advanced treatment of urban sewage

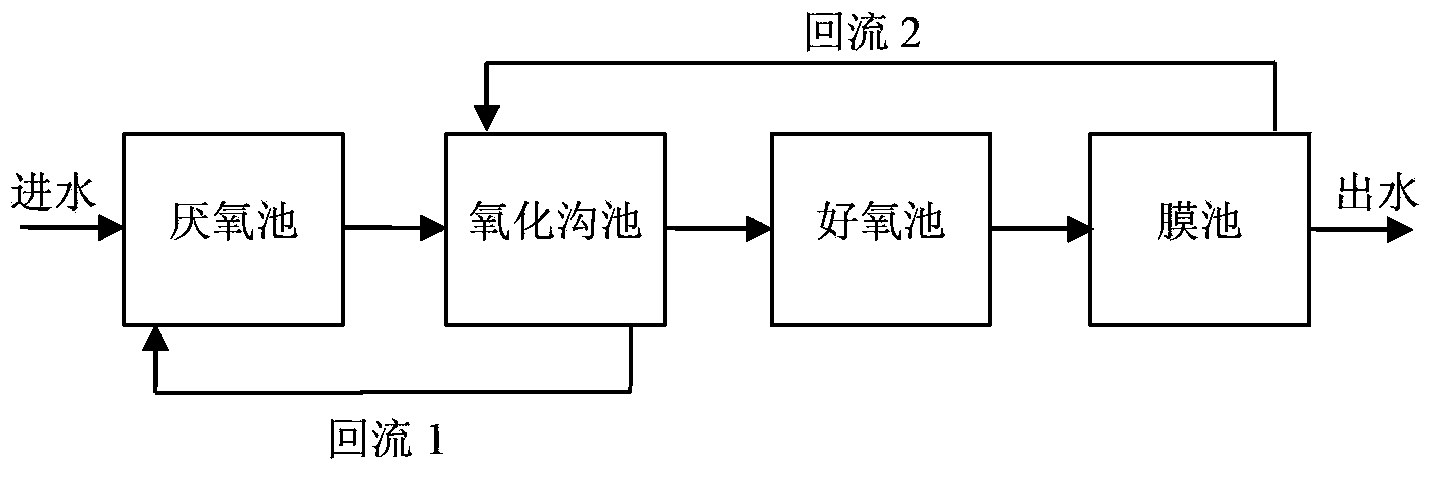

[0067] The urban sewage advanced treatment method is specifically referred to in the appendix figure 1 .

[0068] The implementation steps of this embodiment are as follows:

[0069] The water quality concentration of a pretreated urban sewage is COD cr 212mg / L, ammonia nitrogen 32mg / L, total nitrogen 49mg / L and total phosphorus 2mg / L pretreated sewage, and the return activated sludge mixture from the oxidation ditch pool enters the anaerobic tank, and its reflux ratio is as described 40% of the pretreatment sewage meter. In the anaerobic tank, stir with a stirrer to suspend and mix the activated sludge to achieve dissolved oxygen <0.2mgL, HRT=1h, MLSS=2000mg / L;

[0070] Allow the anaerobic tank to flow out the activated sludge mixed solution into the oxidation ditch pond, and simultaneously allow the activated sludge mixed solution returned from the membrane tank to also enter the oxidation ditch pond, and its reflux ...

Embodiment 2

[0075] Example 2: Advanced treatment of urban sewage

[0076] The urban sewage advanced treatment method is specifically referred to in the appendix figure 1 .

[0077] The implementation steps of this embodiment are as follows:

[0078] The water quality concentration of a pretreated urban sewage is COD cr 812mg / L, ammonia nitrogen 108mg / L, total nitrogen 117mg / L and total phosphorus 19mg / L pretreated sewage, and the backflow activated sludge mixture from the oxidation ditch pond enters the anaerobic tank, and its reflux ratio is as described 150% of the pre-treated sewage meter. In the anaerobic tank, use a stirrer to stir to suspend and mix the activated sludge to achieve dissolved oxygen <0.2mg / L, HRT=3h, MLSS=5000mg / L;

[0079] Allow the anaerobic tank to flow out the activated sludge mixed solution into the oxidation ditch pond, and simultaneously allow the activated sludge mixed solution returned from the membrane tank to also enter the oxidation ditch pond, and its...

Embodiment 3

[0084] Example 3: Advanced treatment of urban sewage

[0085] The urban sewage advanced treatment method is specifically referred to in the appendix figure 1 .

[0086] The implementation steps of this embodiment are as follows:

[0087] The water quality concentration of a pretreated urban sewage is COD cr 870mg / L, ammonia nitrogen 74mg / L, total nitrogen 91mg / L and total phosphorus 11mg / L pretreated sewage, and the return activated sludge mixture from the oxidation ditch pool enters the anaerobic tank, and its reflux ratio is as described 100% of the pre-treated sewage meter. In the anaerobic tank, use a stirrer to stir to suspend and mix the activated sludge to achieve dissolved oxygen <0.2mg / L, HRT=2h, MLSS=4100mg / L;

[0088] Allow the anaerobic tank to flow out the activated sludge mixed solution into the oxidation ditch tank, and simultaneously allow the activated sludge mixed solution returned from the membrane tank to also enter the oxidation ditch tank, and its ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com