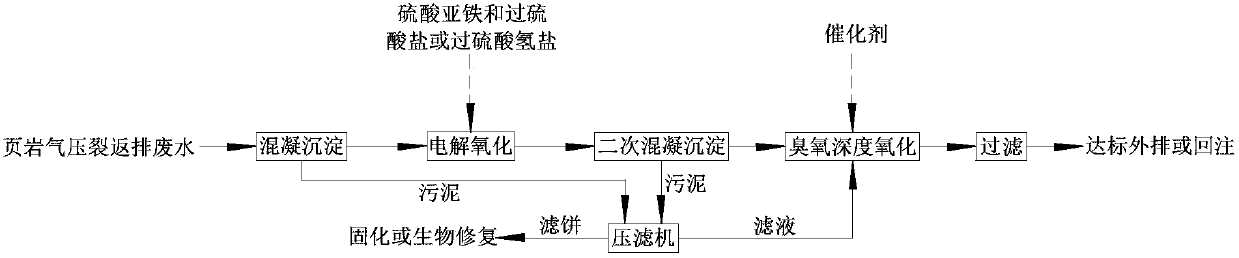

Combined treatment method for shale gas fracturing flowback wastewater

A treatment method and technology for wastewater, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of slow reaction speed, fast indirect oxidation reaction speed and high efficiency, and reduce pollution. , the effect of alleviating water shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Under stirring conditions, a mixture of ferrous sulfate and PFS was dropped into the shale gas fracturing flowback wastewater, the mass ratio of which was 1:1, and the total dosage was 15000mg / L, and the wastewater was adjusted with an alkalizing agent at the same time The pH value is 9.5, then add polymer NSG coagulant 60mg / L, stir rapidly, and stop stirring after a large number of alum flowers are formed; take the effluent after coagulation treatment for electrolytic oxidation treatment, and add ferrous sulfate and Sodium persulfate, its consumption is respectively 4g / L and 5g / L, adjusts the pH value of waste water with alkalizing agent to be 9.0, and the current density of electrolytic oxidation is 50mA / cm 2 , the reaction time is 1.0 hour; carry out secondary coagulation to the wastewater after electrolytic oxidation treatment, add 3000mg / L coagulant ferrous sulfate under stirring conditions, and adjust the pH value of wastewater to 9.0 with an alkalizing ...

Embodiment 2

[0034] Embodiment 2: Under the condition of stirring, drop into the mixture of ferrous sulfate and ferric sulfate in the shale gas fracturing flowback wastewater, its mass ratio is 2:1, the total dosage is 20000mg / L, adjust with alkalizing agent at the same time The pH value of the wastewater is 10.0, then add polyacrylamide coagulant 70mg / L, stir quickly, stop stirring after a large number of alum flowers are formed; take the effluent after coagulation treatment for electrolytic oxidation treatment, and add ferrous sulfate at the same time and sodium persulfate, the dosage is 3g / L and 5g / L respectively, the pH value of wastewater is adjusted to 10.0 with alkalizing agent, and the current density of electrolytic oxidation is 150mA / cm 2 , the reaction time is 1.2 hours; carry out secondary coagulation to the wastewater after electrolytic oxidation treatment, add 4000 mg / L coagulant aluminum sulfate under stirring conditions, and adjust the pH value of the wastewater to 10.0 with...

Embodiment 3

[0035] Example 3: Under stirring conditions, ferrous sulfate was added to the shale gas fracturing flowback wastewater at a dosage of 18,000 mg / L. At the same time, the pH value of the wastewater was adjusted to 9.3 with an alkalizing agent, and then polyacrylamide was added to aid coagulation 65mg / L, stirring quickly, stop stirring after a large amount of alum flowers are formed; take the effluent after coagulation treatment for electrolytic oxidation treatment, and add ferrous sulfate and sodium persulfate at the same time, the dosage is 4g / L and 6g respectively / L, adjust the pH value of wastewater to 9.5 with alkalizing agent, and the current density of electrolytic oxidation is 200mA / cm 2 , the reaction time is 0.8 hours; carry out secondary coagulation to the wastewater after electrolytic oxidation treatment, add 2500 mg / L coagulant ferrous sulfate under stirring conditions, and adjust the pH value of the wastewater to 9.5 with an alkalizing agent at the same time, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com