Method for processing dye wastewater by applying nanocomposite photocatalyst combination-Fenton

A dye wastewater and photocatalyst technology, which is applied in the fields of light water/sewage treatment, oxidized water/sewage treatment, textile industry wastewater treatment, etc. The effect of processing efficiency, reducing dosage and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

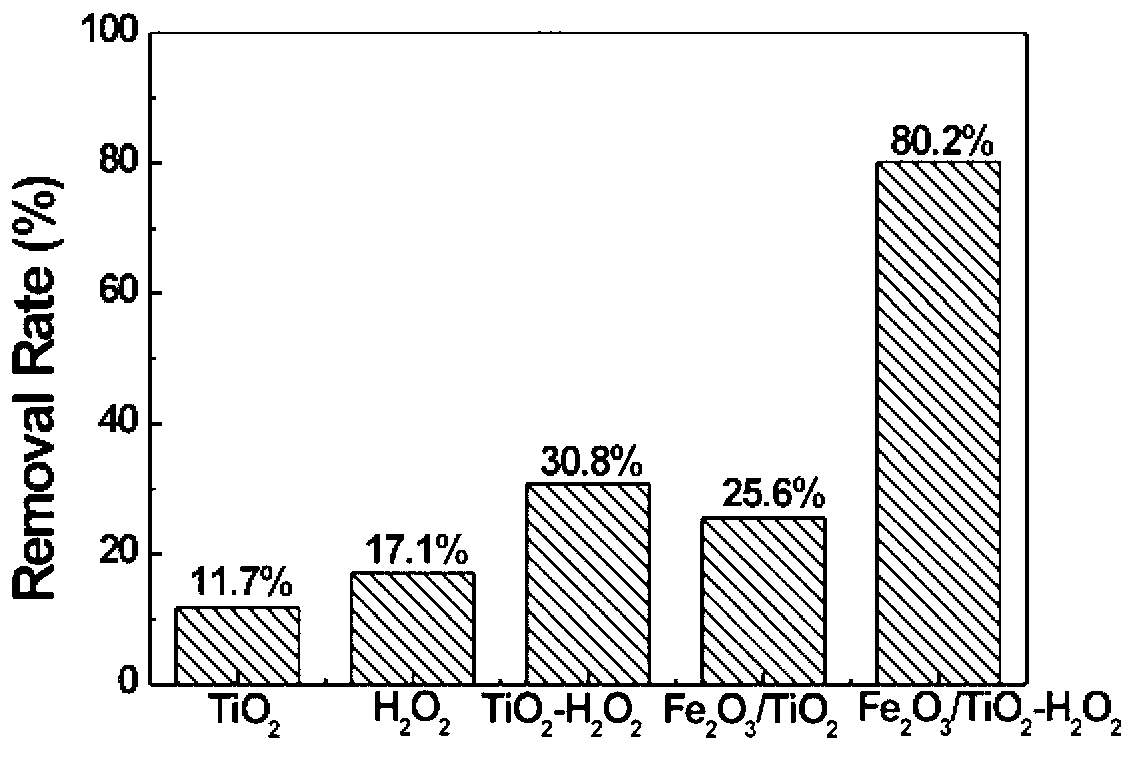

Embodiment 1

[0030] (1) The base material is an industrial Ti plate with a thickness of 2mm and a size of 2cm×3cm. The surface is polished with metallographic sandpaper until there are no scratches, cleaned ultrasonically with acetone, ethanol and three times of water, and dried for later use. Prepare an electrolyte solution of 0.5wt% HF, use the industrial Ti plate as the anode and platinum as the counter electrode at room temperature, electrochemical anodize at 30V for 1h, and then heat treat at 500°C for 2h, that is, on the surface of the industrial Ti plate Obtain ordered TiO 2 Nanotube array photocatalyst, that is, Ti-based TiO 2 Nanotube Array Photocatalysts.

[0031] (2) Ti-based TiO 2 Nanotube array photocatalysts for degradation of dye wastewater. 200mL, 50mg L -1 The dye wastewater is placed in the reactor, the pH of the system is adjusted to 6.5, and then the titanium-based TiO 2 Nanotube Array Photocatalysts. At the beginning of the reaction, air was introduced in a dark ...

Embodiment 2

[0034] h 2 o 2 Degradation of dye wastewater. 200mL, 50mg L -1 The dye wastewater is placed in the reactor, the pH value is adjusted to 6.5, and 0.125mmol H 2 o 2 , and then degrade the dye wastewater under the irradiation of a 200W ultra-high pressure spherical mercury lamp, take water samples every 30 minutes, measure the change of the absorbance of the dye wastewater, and obtain the degradation rate of the dye wastewater.

Embodiment 3

[0036] h 2 o 2 Degradation of dye wastewater. 200mL, 50mg L -1 The dye wastewater is placed in the reactor, the pH value is adjusted to 6.5, and 0.375mmol H 2 o 2 , and then degrade the dye wastewater under the irradiation of a 200W ultra-high pressure spherical mercury lamp, take water samples every 30 minutes, measure the change of the absorbance of the dye wastewater, and obtain the degradation rate of the dye wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com