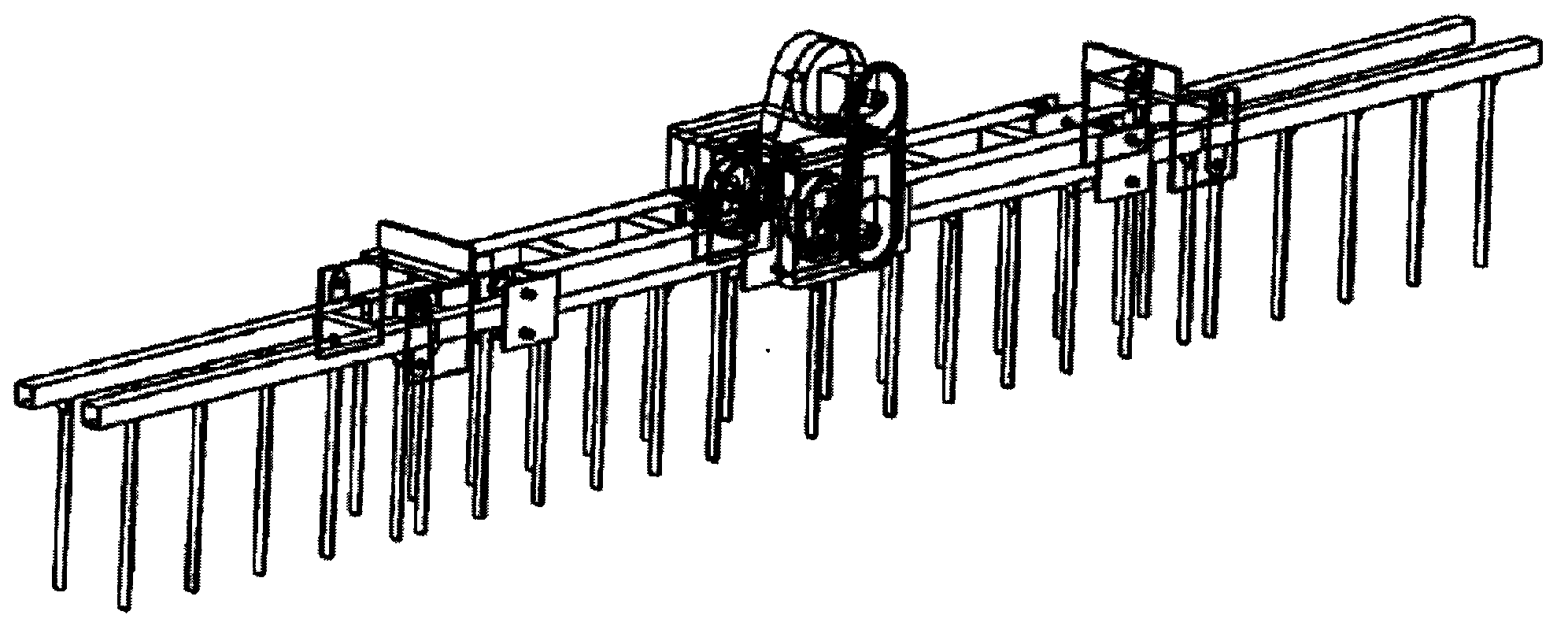

Foldable swinging live ballast machine for salt pond

A ballast machine and swing type technology, applied in the direction of alkali metal chloride, etc., can solve the problems of difficult driving and transportation outside the salt pool, damage to the bottom plate of the salt pool, large resistance, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

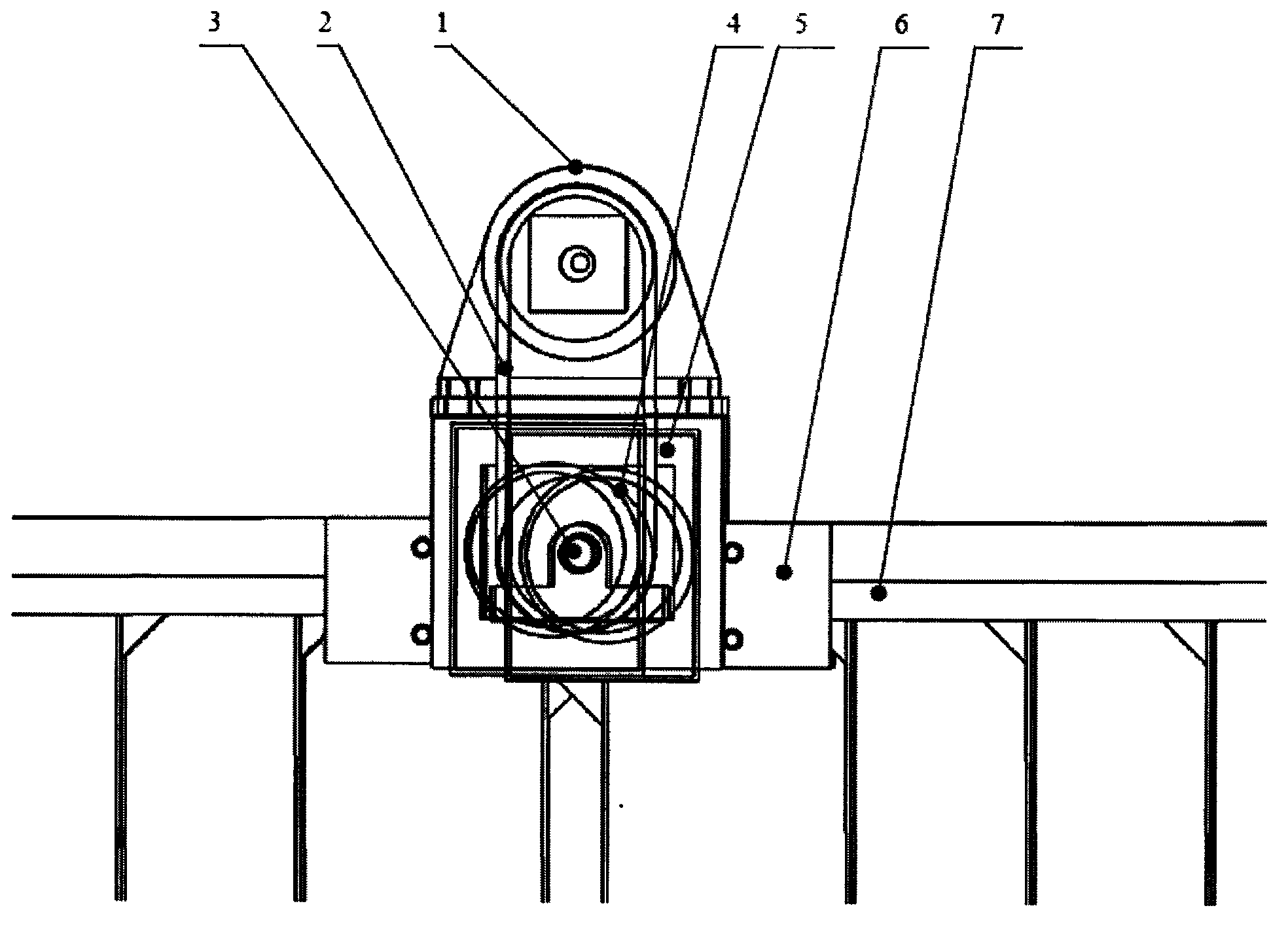

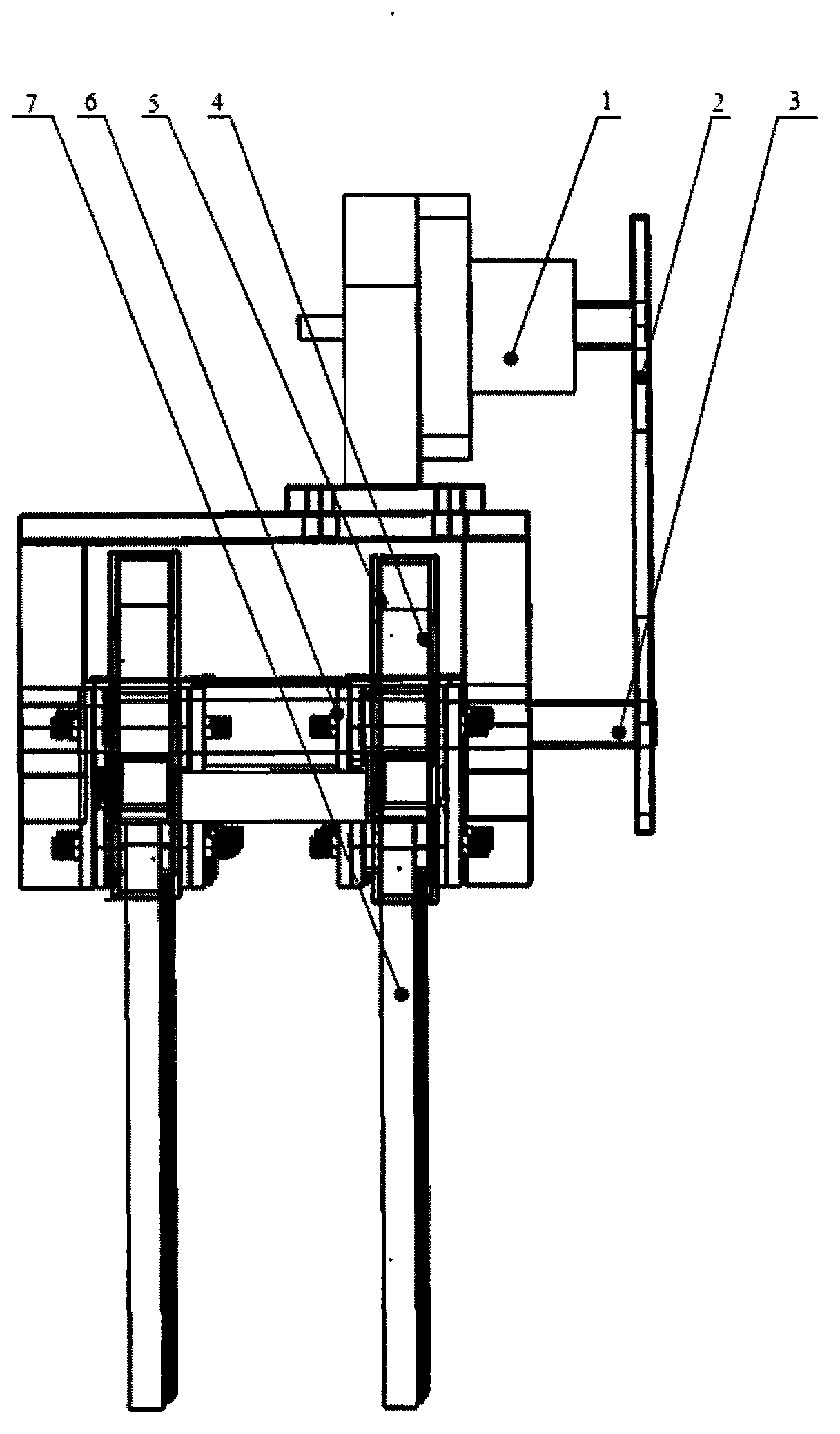

[0012] The ballast machine reducer (1) transmits power to the main shaft (3) through the transmission chain (2). The main shaft (3) drives two cams (4) in opposite directions to rotate, and the two cams (4) each drive a follower The body (5) moves, and the driven body (5) is connected with the rake body (7) to form a left and right reciprocating swing on the bearing (6), thereby realizing the purpose of performing live ballast operation on the salt layer at the bottom of the salt pond. When the live ballast machine is driven by a tractor outside the salt pond, the pin (11) is pulled out, the two ends of the rake body can be folded, and the part of the rake body connected by the connecting plate (9) and the rotating shaft (10) can be turned towards Fold up in the middle and fix it on the stop block (8); on the contrary, put the rake body down to a horizontal state, and then insert the pin (11), then live ballast operation can be carried out in the salt pond.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com