Machining tooling fixture for welding joint tensile sample and clamping and positioning method for machining tooling fixture

A technology for fixtures and tensile samples, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problem of not meeting the processing requirements of welded joint tensile samples, affecting the manufacturing progress, and poor verticality of samples, etc. problems, to achieve the effect of improving machining efficiency, reducing processing costs, and positioning reasonably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

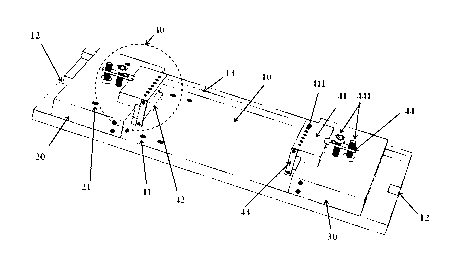

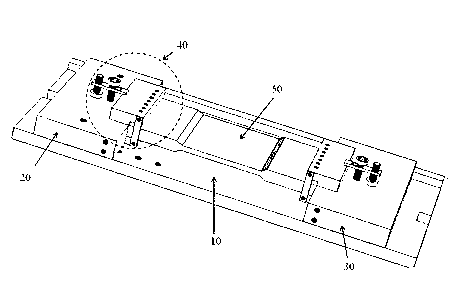

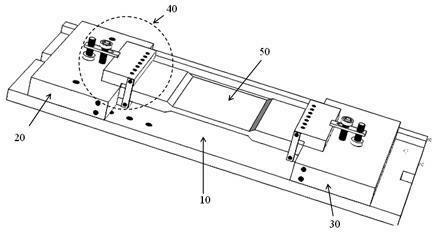

[0035] The present invention provides a machining tooling fixture (hereinafter also referred to as a tooling fixture) for positioning a welded joint tensile specimen (hereinafter also referred to as a tensile specimen, or specimen) during processing. Combine figure 1 , figure 2 The following will mainly describe a specific implementation structure when the above tooling fixture is used to position a plate-shaped sample.

[0036] See also figure 1 , figure 2 As shown, the tooling fixture of the present invention mainly includes: a base 10, a movable support block 20, a fixed support block 30, and two clamping parts 40 of the sample clamping device. The "length direction" of each part in the text refers to the direction that is consistent with the length of the clamp; for any two parts in the clamp that are arranged opposite to each other, "inside" refers to the side close to each other, "outside" It is the side away from each other.

[0037] A number of positioning grooves 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com