Conical surface segment mould processing method and segment mould

A technology of active molds and processing methods, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve problems such as CNC machining program errors, inconsistent inclination angles, reworked workpieces, etc., to ensure accuracy, avoid errors, and save processing procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention includes a method for processing a conical surface movable mold, which comprises the following steps:

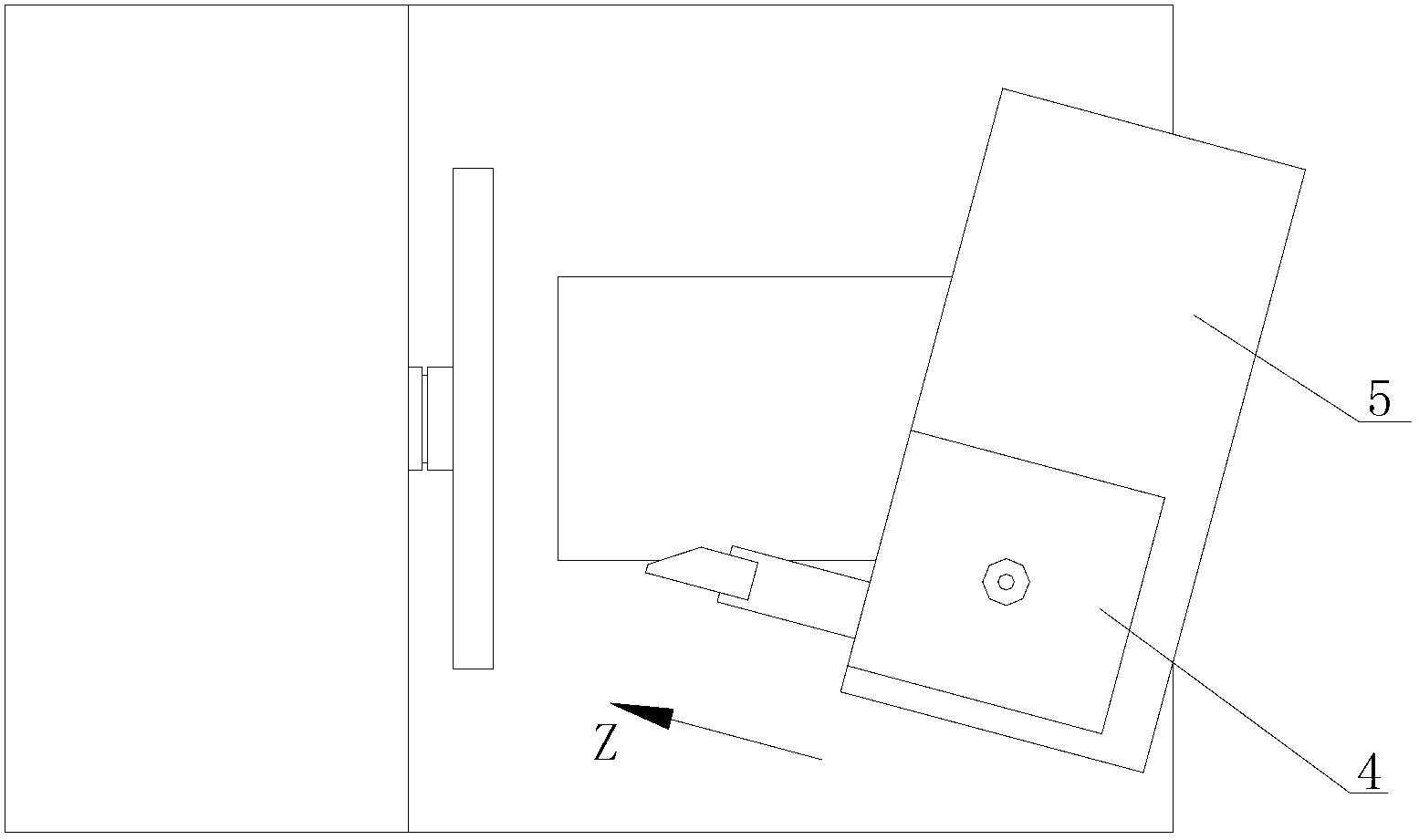

[0022] In the first step, the workpiece to be processed is clamped and fixed on the face plate 2 of the machine tool, and the turning tool is installed on the tool holder 4 as the tool 3 .

[0023] The second step is to establish a coordinate system on the processing machine tool. The coordinate system includes X-axis and Z-axis, wherein the X-axis is vertical and parallel to the surface of the machine tool face; the Z-axis is horizontal and clamped at 15° on the surface of the machine tool face Angle, the included angle is equal to the conical half angle of the conical surface;

[0024] The third step is to move the tool rest 4 to the edge of the workpiece to be processed along the longitudinal moving frame 6 of the tool frame, and then start the machine tool. The rotation of the machine tool disk 2 drives the continuous rotation of the workpiece to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com